TM 5-3895-359-14&P

Bearing shells are available in .010", .020" and .030 "

After removal, clean the bearings and inspect them for

scoring, pitting, flaking, chipping, cracking, loss of

undersize for service with reground crankshafts. To

determine the size bearings required, refer to

babbitt or signs of overheating. If any of these defects

are present, the bearings must be discarded. However,

Crankshaft Grinding on Page 10-2-52. Bearings which

are .002" undersize are available to compensate for

babbitt plated bearings may develop minute cracks or

slight journal wear where it is unnecessary to regrind the

small isolated cavities on the bearing surface during

crankshaft.

engine operation. These are characteristics of and are

NOT detrimental to this type of bearing. The bearings

should not be replaced for these minor surface

NOTE: Bearing shells are NOT reworkable

imperfections. The upper bearing shells, which carry

from one undersize to another under any

the load, will normally show signs of distress before the

circumstances.

lower bearing shells do.

Install Connecting Rod Bearing Shells

Inspect the backs of the bearing shells for bright spots

With the crankshaft and the piston and connecting rod

which indicate they have been shifting in their supports.

assembly in place, install the connecting rod bearings as

If such spots are present, discard the bearing shells.

follows:

Also inspect the connecting rod bearing bore for burrs,

foreign particles, etc.

1. Rotate the crankshaft until the connecting rod journal

is at the bottom of its travel, then wipe the journal clean

Measure the thickness of the bearing shells, using a

and lubricate it with clean engine oil.

micrometer and ball attachment J 4757, as described

2. Install the upper bearing shell -the one with the short

under Inspection on Page 10-2-60. The minimum

groove and oil hole at each parting line -in the

thickness of a worn standard connecting rod bearing

connecting rod. Be sure the tang on the bearing shell

shell should not be less than .1530" and, if either

fits in the groove in the connecting rod.

bearing shell is thinner than this dimension, replace both

3. Pull the piston and rod assembly down until the

bearing shells. A new standard bearing shell has a

upper rod bearing seats firmly on the crankshaft journal.

thickness of .1548" to .1553". Refer to Table 1.

4. Note the numbers stamped on the connecting rod

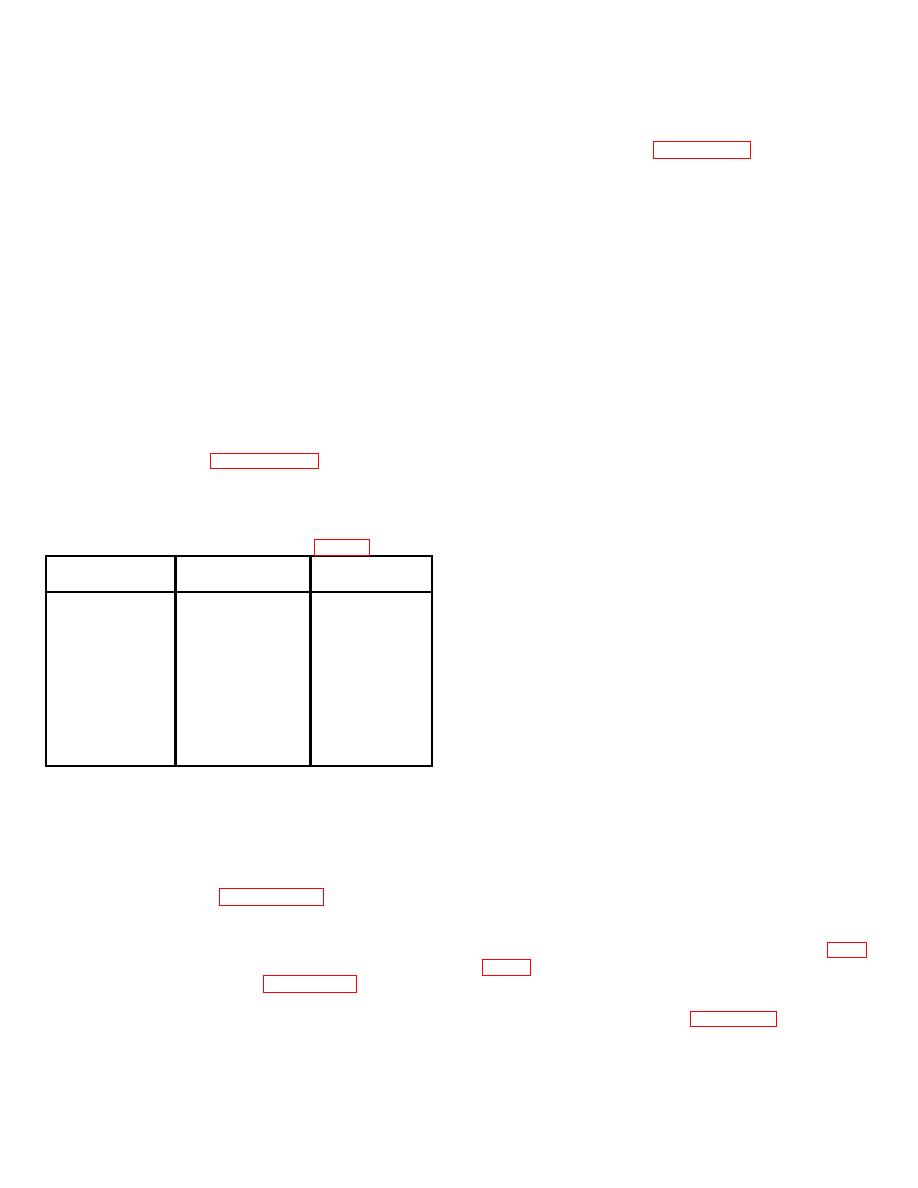

Bearing

'New Bearing

Minimum Worn

and the bearing cap and install the lower bearing shell -

Size

Thickness

Thickness

the one with the continuous oil groove -in the bearing

cap, with the tang on the bearing shell in the groove in

the bearing cap.

Standard

.1548"/. 1553"

.1530"

5.

Install the bearing and cap and tighten the

connecting rod bolt nuts to 60-70 lb-ft (81-95 N )

.002" Undersize

.1558".1563"

/

.1540"

m

torque (lubrite nut) or 65-75 lb-ft (88-102 N ) torque

m

.010" Undersize

.1598"/.1603"

.1580"

(castellated nut).

.020" Undersize

.1648"/.1653"

.1630"

NOTE: Be sure the connecting rod bolt has not

turned in the connecting rod before torque is

.030" Undersize

.1698"/.1703"

.1 680"

applied to the nut.

*Thickness 90from parting line of bearing.

TABLE 1

6. Install the lubricating oil pump and the oil inlet and

In addition to the thickness measurement, check the

outlet pipes.

clearance between the connecting rod bearing shells

and the crankshaft journal. This clearance may be

NOTE: If shims were used between the oil

checked by means of a soft plastic measuring strip

pump body and the main bearing caps, install

which is squeezed between the journal and the bearing

the shims in exactly the same location from

(refer to Shop Notes on Page 10-2-131.) The maximum

which they were removed.

connecting rod bearing-to-journal clearance with used

parts is .006" .

7. Install the oil pan, using a new gasket.

8. Refer to the Lubricating Oil Specifications on Page

Before installing the bearings, inspect the crankshaft

journals (refer to Inspection on Page 10-2-49).

dipstick.

If new bearings were installed, operate the engine on the

Do not replace one connecting rod bearing shell alone.

run-in schedule as outlined on Page 10-9-2.

If one bearing shell requires replacement, install both

new upper and lower bearing shells. Also, if a new or

reground crankshaft is to be used, install all new bearing

shells.

10-2-91