TM 5-3895-359-14&P

If main hearing trouble is suspected, remove the oil pan,

a. To remove all except the rear main bearing

then remove the main hearing caps, one at a time, as

shell, insert a 1/4 " x I " bolt with a 1/2 "

outlined below and examine the bearing shells.

diameter and 1/16" thick head (made from a

standard bolt) into the crankshaft journal oil

Remove Main Bearing Shells (Crankshaft in Place)

hole. Then revolve the shaft to the right

The bearing caps are numbered 1. 2, 3, etc., indicating

(clockwise) and roll the bearing shell out of

their respective positions and, when removed, must

position as shown in Fig. 3. The head of the

always be reinstalled in their original position.

bolt must not extend beyond the outside

All crankshaft main bearing journals, except the rear

diameter of the bearing shell.

journal, are drilled for an oil passage. Therefore, the

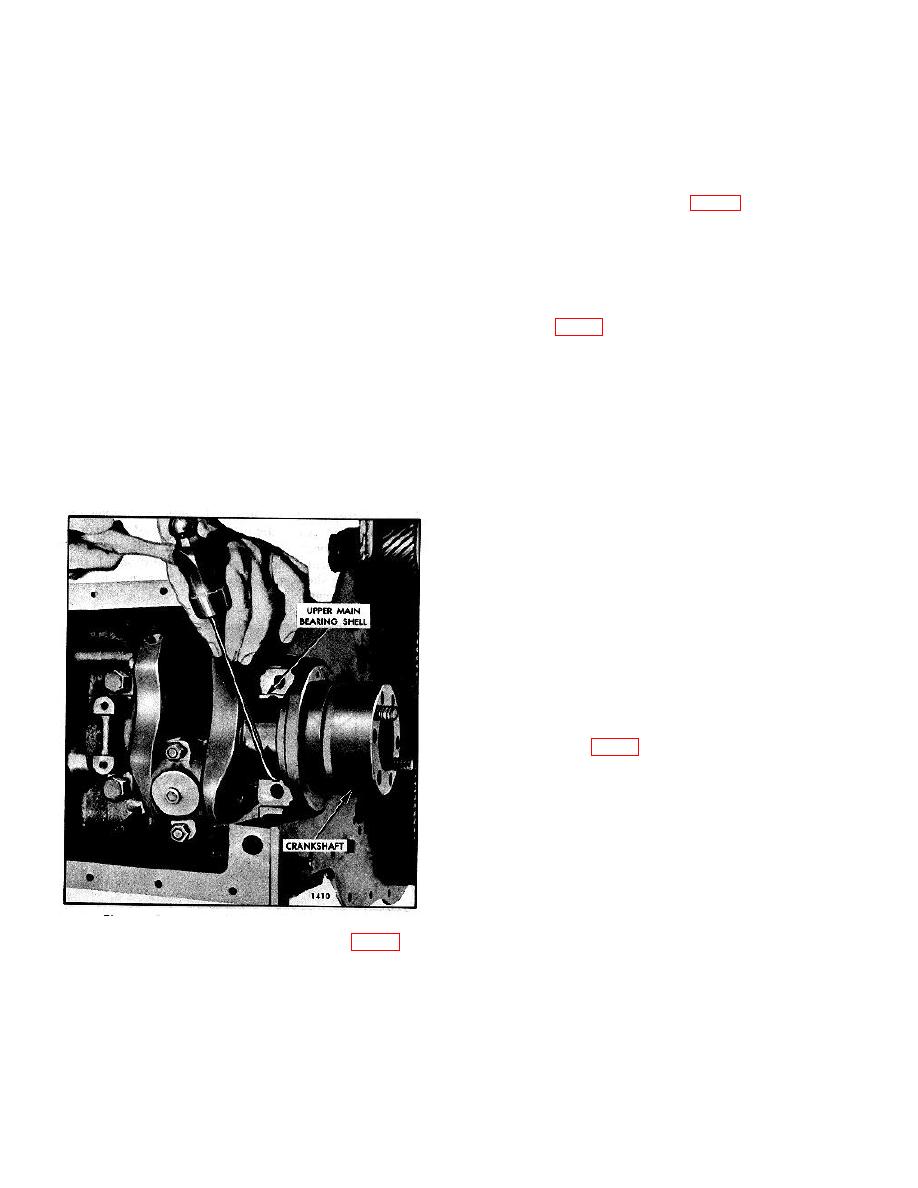

b. Remove the rear main bearing upper shell by

procedure for removing the upper bearing shells with the

tapping on the edge of the bearing with a small

crankshaft in place is somewhat different on the drilled

curved rod, revolving the crankshaft at the

journals than on the rear journal.

same time to roll the bearing shell out as shown

Remove the main bearing shells as follows:

in Fig. 4.

1. Drain and remove the oil pan to expose the main

c. The lower halves of the crankshaft thrust

bearing caps.

washers will be removed along with the rear

2. Remove the oil pump and the oil inlet and outlet pipe

main bearing cap. The upper halves of the

assemblies.

washers can be removed for inspection by

NOTE

pushing on the ends of the washers with a small

If shims are used between the oil

rod, forcing them around and out of the main

pump and the main bearing caps,

bearing support.

save the shims so that they may be

reinstalled in exactly the same

Inspection

location.

Bearing failures may result from deterioration (acid

formation) or contamination of the oil or loss of oil. An

analysis of the lubricating oil may be required to

determine if corrosive acid and sulphur are present

which cause acid etching, flaking and pitting. Bearing

seizure may be due to low oil or no oil.

Check the oil filter elements and replace them if

necessary. Also. check the oil by-pass valve to make

sure it is operating freely.

After removal, clean the bearings and inspect them for

scoring, pitting, flaking, etching, loss of babbitt or signs

of overheating (Fig. 5). The lower bearing shells, which

carry the load, will normally show signs of distress

before the upper bearing shells. However, babbitt

plated bearings may develop minute cracks or small

isolated cavities on the bearing surface during engine

operation. These are characteristics of and are not

detrimental to this type of bearing. They should not be

replaced for these minor surface imperfections since

function of the bearings is in no way impaired and they

will give many additional hours of trouble-free operation.

Fig. 4. Removing Upper Rear Main Bearing Shell

Inspect the backs of the bearing shells for bright spots

3. Remove one main bearing cap at a time (Fig. 2) and

which indicate they have been moving in the bearing

inspect the bearing shells as outlined under Inspection.

caps or bearing supports. If such spots are present,

Reinstall each bearing shell and bearing cap before

discard the bearing shells.

removing another bearing cap:

10-2-60