TM 5-3895-359-14&P

SHOP NOTES - TROUBLE SHOOTING

SPECIFICATIONS - SERVICE TOOLS

SHOP NOTES

TEFLON WRAPPED PIPE PLUG

2.

Start the tape one or two threads from the small or

Pipe plugs with a baked teflon coating are available for

leading edge of the plug, joining the tape together with

service. However, pipe plugs can be hand wrapped

an overlap of approximately 1/8"

satisfactorily with teflon tape to provide a better seal and

facilitate plug removal. When a teflon wrapped plug is

3.

Wrap the tape tightly in the same direction as you

installed, it is extremely important that the specified

would turn a nut. The tape must conform to the

torque not be exceeded.

configuration of the threads (be pressed into the minor

diameter of the threads) without cutting or ripping the

Hand wrap a pipe plug with teflon tape as follows:

tape.

1.

Be sure the pipe plug is thoroughly clean and dry

4.

Hand tighten and hand torque the pipe plug and

prior to applying the teflon tape. All dirt, grease, oil and

do not exceed the specified torque. Do not use power

scale must be removed.

tools.

CHECKING BEARING CLEARANCES

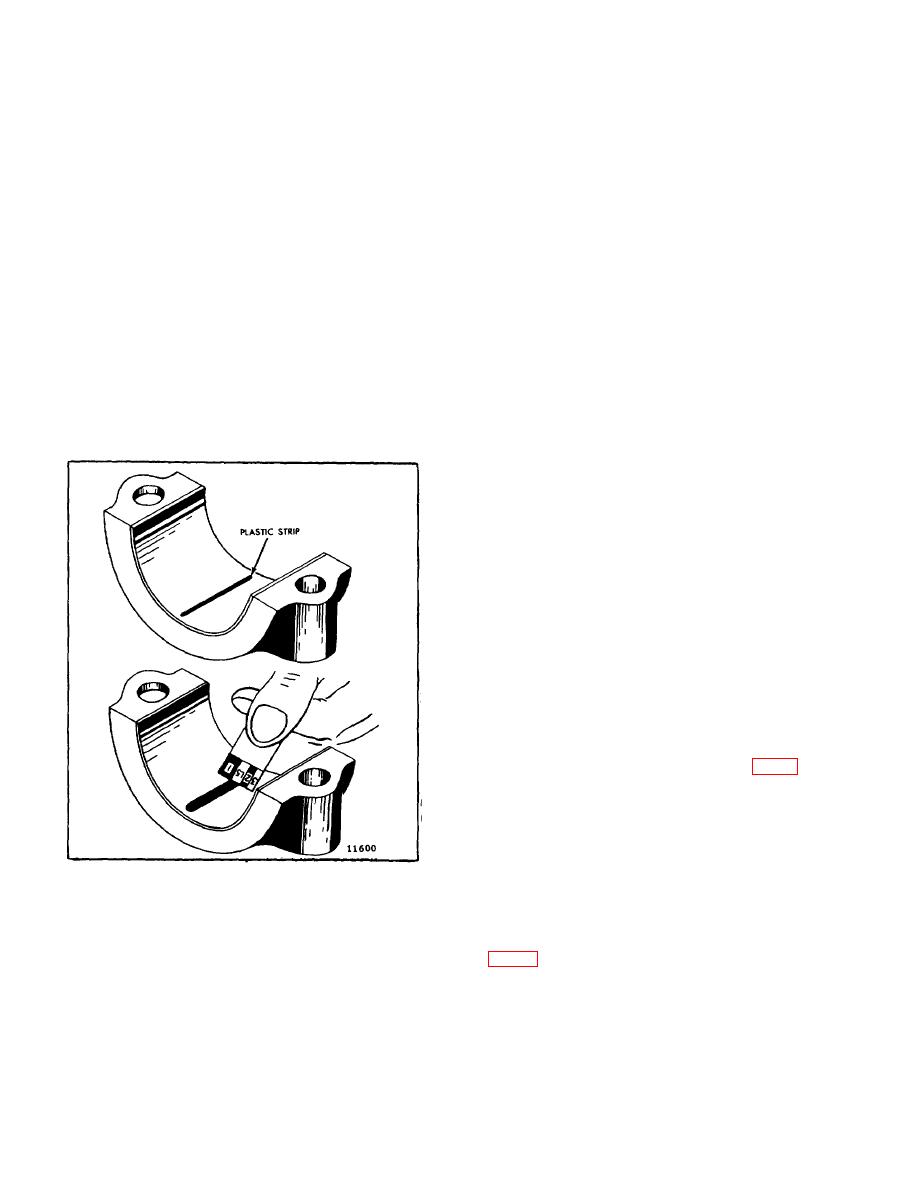

The plastic strip may be used for checking the bearing

clearances as follows:

1.

Remove the bearing cap and wipe the oil from the

bearing shell and the crankshaft journal.

NOTE:

When checking the main

bearing clearances with the engine in

a position where the main bearing

caps are supporting the weight of the

crankshaft and the flywheel, an

erroneous reading, due to the weight

of the crankshaft and flywheel, can

be eliminated by supporting the

weight of the crankshaft with a jack

under the counterweight adjoining

the bearing being checked.

2.

Place a piece of the plastic strip the full width of

the bearing shell, about 1/4" off center (Fig. 1).

3.

Rotate the crankshaft about 30 from bottom dead

center and reinstall the bearing cap. Tighten the bolts to

the specified torque.

4.

Remove the bearing cap. The flattened plastic

Fig. 1. Using Plastic Strip to Measure Bearing-to-

strip will be found adhering to either the bearing shell or

Crankshaft Clearance

the crankshaft.

A strip of soft plastic squeezed between the crankshaft

5.

Compare the width of the flattened plastic strip at

journal and the connecting rod bearing or main bearing

its widest point with the graduations on the envelope

may be used to measure the bearing clearances.

The strip is a specially molded plastic "wire"

envelope indicates the bearing clearance in thousandths

manufactured commercially and is available in three

of an inch. Taper may be indicated when one end of the

sizes and colors. Type PG-1 (green) has a clearance

flattened plastic strip is wider than the other. Measure

range of .001" to .003", type PR-1 (red) has a range of

each end of the plastic; the difference between the

.002" to .006" and type PB-1 (blue) has a range of .004"

readings is the approximate amount of taper.

to .009".

10-2-131