TM 5-3895-359-14&P

5. Remove all of the accessories and assemblies with

18. Remove the thrust washers from each side of the

their attaching parts as necessary to permit the engine

rear main bearing.

to be mounted on an overhaul stand.

19. Remove the pistons, connecting rods and liners.

6. Mount the engine on an overhaul stand and fasten it

securely to the mounting plate.

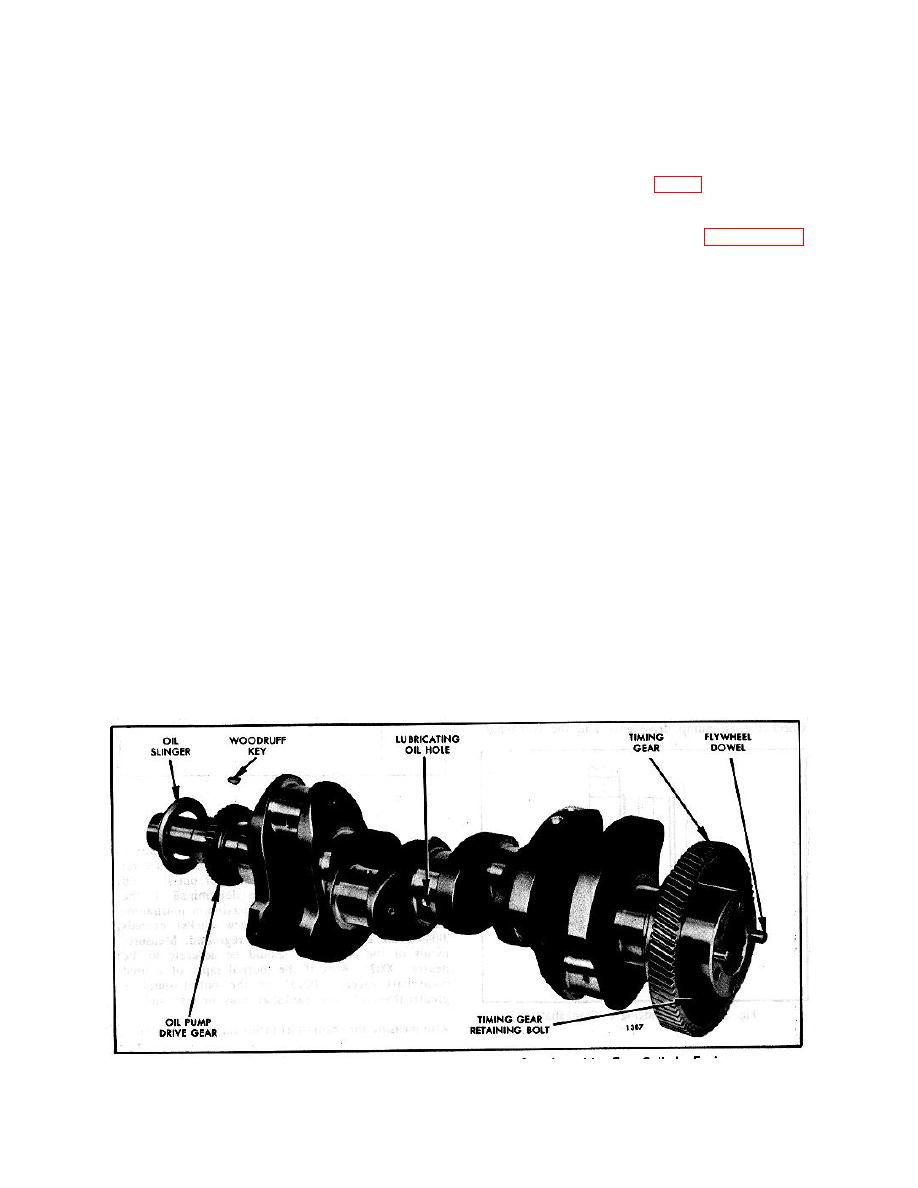

20. Remove the crankshaft, including the timing gear

and oil pump drive gear (Fig. 2).

WARNING

21.

Refer to Page 10-2.123 for removal of the

Be absolutely sure the engine is

crankshaft timing gear and Page 10-5-9 for the

securely attached to the stand before

procedure covering removal of the oil pump drive gear.

releasing the lifting sling. Severe

injury to personnel and destruction

Inspection

of engine parts will result if the

engine breaks away from the stand.

After the crankshaft has been removed, clean and

inspect it thoroughly before reinstalling it in the engine.

7. Remove the oil pan.

Remove the plugs and clean out the oil passages

8. Remove the lubricating oil pump.

thoroughly with a stiff wire brush. Clean the crankshaft

with fuel oil and dry it with compressed air. Then

9. Remove the flywheel and flywheel housing.

reinstall the plugs.

10. Remove the crankshaft pulley.

Inspect the keyways for evidence of cracks or wear.

Replace the crankshaft, if necessary.

11. Remove the vibration damper.

If the crankshaft shows evidence of excessive

12. Remove the front engine support.

overheating, replace the crankshaft since the heat

treatment has probably been destroyed.

13. Remove the crankshaft front cover.

Used crankshafts will sometimes show a certain amount

14. Remove the vibration damper inner cone or oil seal

of ridging caused by the groove in the upper

spacer.

15. Remove the cylinder head.

16. Remove the connecting rod bearing caps.

17. Remove the main bearing caps.

Fig. 2. Typical Crankshaft, Timing Gear and Oil Pump Drive Gear Assembly-Four Cylinder Engine

10-2-49