TM 5-3895-359-14&P

CONNECTING ROD

Cross-Head Type Piston

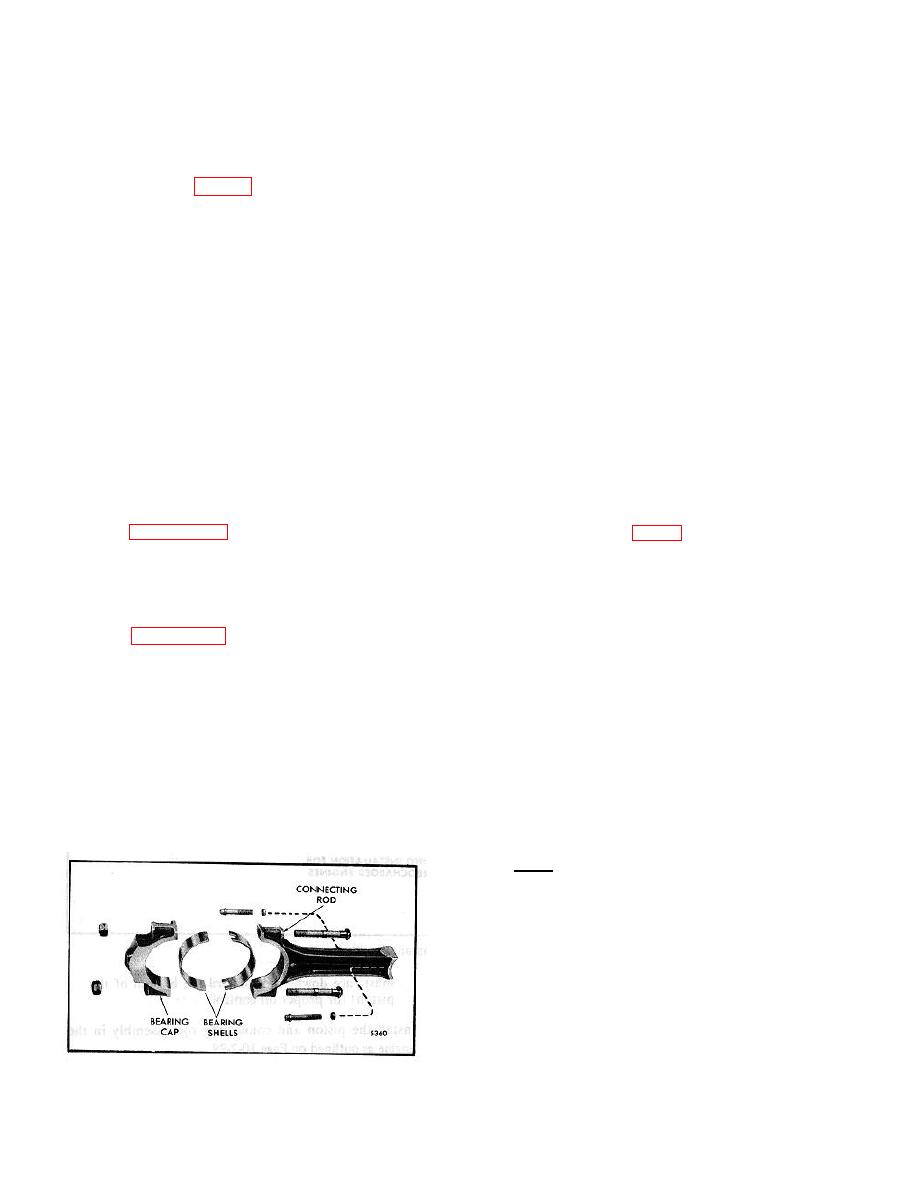

The connecting rod (Fig. 1) is forged to an "I" section

NOTE: Never use crocus cloth on the bearing

with an open or saddle type contour at the upper end

side of the pin.

and a bearing cap at the lower end. The bearing cap

and connecting rod are forged in one piece and bored

Connecting rods being removed from an original build

prior to separation.

engine can be reused as is, after considering the

following:

The upper end of the connecting rod is machined to

1. Check for visual damage (bent).

match the contour of the piston pin. The piston pin is

2. A previous bearing(s) or related failure.

secured to the connecting rod with two self-locking bolts

3. Is the connecting rod blue at the top or bottom end?

and spacers. The bearing cap is secured to the

4. Fretting at split line between the connecting rod and

connecting rod by two specially machined bolts and

cap.

nuts.

5. Excessive pound-in of the bolt head or nut.

Lubricating oil is forced through a drilled oil passage in

If the connecting rod has been subjected to any of the

the connecting rod to the piston pin and bushing.

above, it should be scrapped.

A service connecting rod includes the bearing cap and

In qualifying a used connecting rod from a source other

the attaching bolts and nuts.

than an original build engine, the following checks

should be made in addition to the above.

The replaceable connecting rod bearing shells are

covered on Page 10-2-90.

1. Check for cracks (Fig. 2) by the magnetic particle

method outlined on Page 10-2.49 under Crankshaft

Disassemble Connecting Rod from Piston

Inspection.

With the rod and piston assembly removed from the

2. Determine bore diameter of the rod, using a dial bore

engine, disassemble the piston and connecting rod as

gage and master ring as follows (Fig. 3).

outlined on Page 10-2-79.

a. Install the connecting rod cap on the connecting rod

Inspection

and tighten the bolt nuts to 60-70 lb ft (81-95 N )

m

torque.

Clean the connecting rod and piston pin with a

suitable solvent and dry them with compressed air.

Blow compressed air through the oil passage in the

rod bolt nuts. Over torque may permanently

connecting rod to be sure it is clear of obstructions. Use

distort the connecting rod cap.

crocus cloth, wet with fuel oil, to remove any trace of

fretting and/or corrosion on the connecting rod saddle

b. Measure diameter A and B as shown in Fig. 3.

and piston pin contact surface with the rod before

reassembly.

c. Obtain average of A and B to obtain size at split line.

A+B

=

X

which is the average of A + B

2

d. Measure C. The difference in the results of the

measurements X and C gives bore out-of-round and can

be .005 " maximum.

e. Add C with X and average to obtain average bore

size.

Fig. 1. Connecting Rod Details.

10-2-86