TM 5-3895-359-14&P

CONNECTING ROD BEARINGS

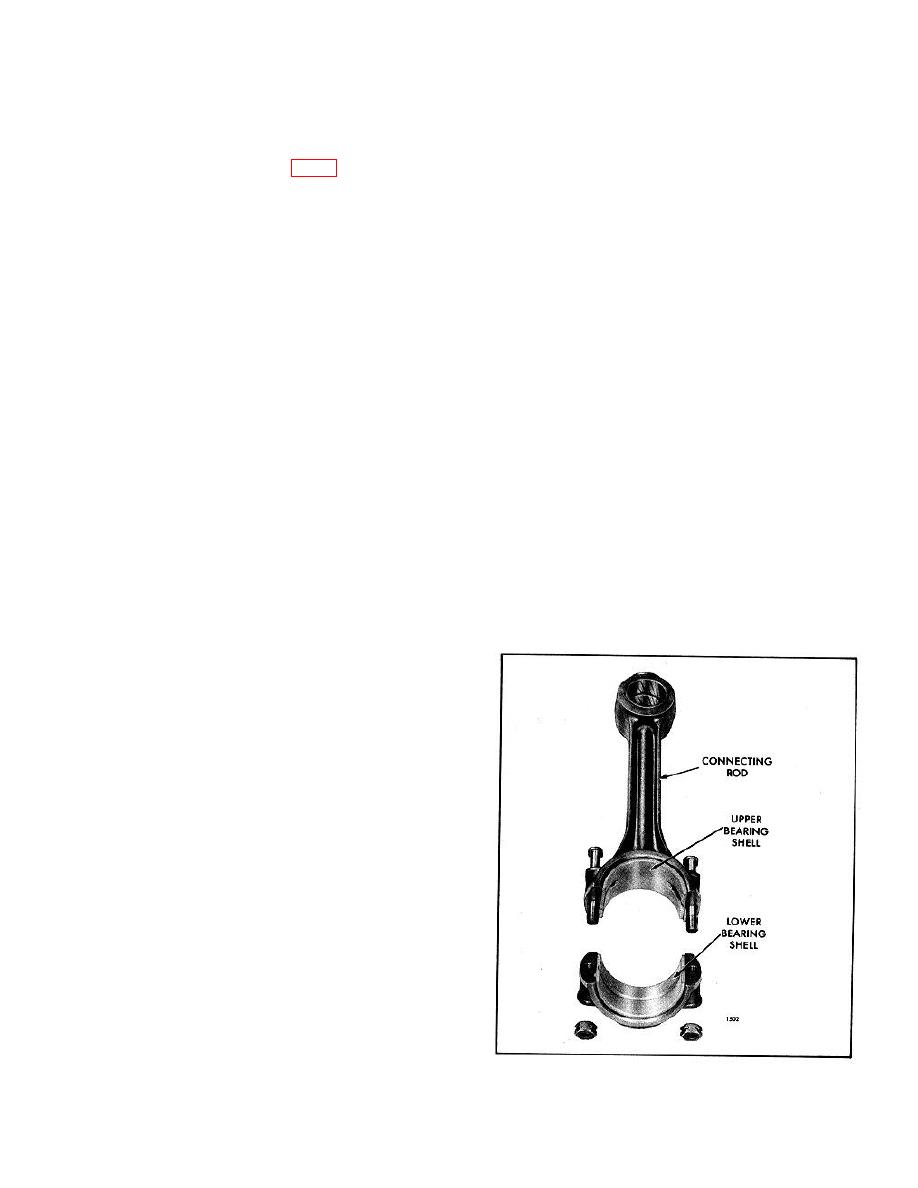

The connecting rod bearing shells (Fig. 1) are precision

NOTE: If shims are used between the oil pump

made and are replaceable without shim adjustments.

body and the main bearing caps, save the shims

They consist of an upper bearing shell seated in the

so they may be reinstalled when installing the oil

connecting rod and a lower bearing shell seated in the

pump.

connecting rod cap. The bearing shells are prevented

from endwise or radial movement by a tang at the

parting line at one end of each bearing shell.

3. Remove one connecting rod bearing cap. Push the

piston and rod assembly up into the cylinder liner far

Various types of bearings have been used. Currently,

enough to permit removal of the upper bearing shell.

multiple layer copper-lead coplated or aluminum

Do not pound on the edge of the bearing shell with a

triplated bearings are in use. These bearings have an

sharp tool.

inner surface, called the matrix, of copper-lead or

aluminum. A thin deposit of babbitt is then plated onto

4. Inspect the upper and lower bearing shells as

the matrix. This babbitt overlay has excellent resistance

outlined under Inspection.

to friction, corrosion and scoring tendencies which,

combined with the material of the matrix, provides

5. Install the bearing shells and bearing cap before

improved load carrying characteristics. These bearings

another connecting rod bearing cap is removed.

are identified by the satin silver sheen of the babbitt

when new and a dull gray after being in service. The

former copper-lead bearings had a copper color when

Inspection

new and turned very dark during engine operation.

Bearing failures may result from deterioration (acid

The upper and lower connecting rod bearing shells are

formation) or contamination of the oil or loss of oil. An

different and are not interchangeable.

The upper

analysis of the lubricating oil may be required to

bearing shell is grooved midway between the bearing

determine if corrosive acid and sulphur are present

edges, part way up from each parting line, with an oil

which cause acid etching, flaking and pitting. Bearing

hole through the shell at the termination of each groove.

seizure may be due to low oil or no oil.

The lower bearing shell has a continuous oil groove,

extending from one parting line to the other, in line with

that of the upper bearing shell. These grooves maintain

a continuous registry with the oil hole in the crankshaft

connecting rod journal, thereby providing a constant

supply of lubricating oil to the connecting rod bearings,

piston pin bushings and spray nozzle through the oil

passage in the connecting rod.

Remove Bearing Shells

The connecting rod bearing caps are numbered 1, 2, 3,

etc., with matching numbers stamped on the connecting

rods. When removed, each bearing cap and the bearing

shells must always be reinstalled on the original

connecting rod.

Remove the connecting rod bearings as follows:

1. Drain the oil and remove the oil pan.

2. Remove the lubricating oil pump and the pump inlet

and outlet pipes.

Fig. 1 - Connecting Rod and Bearing Shells

10-2-90