TM 5-3895-359-14&P

ENGINE RUN-IN INSTRUCTIONS

A basic engine includes only those items actually

required to run the engine. The addition of any engine

Following a complete overhaul or any major repair job

driven accessories will result in a brake horsepower

involving the installation of piston rings, pistons, cylinder

figure less than the values shown in the Basic Engine

liners or bearings, the engine should be "Run-In" on a

Run-In Schedule. The following items are included on

dynamometer prior to release for service.

the basic engine: blower, fuel pump, water pump and

governor. The fan and battery-charging generator typify

The dynamometer is a device for applying specific loads

accessories not considered on the basic engine.

to an engine. It permits the serviceman to physically

and visually inspect and check the engine while it is

operating. It is an excellent method of detecting

improper tune-up, misfiring injectors, low compression

and other malfunctions, and may save an engine from

damage at a later date.

The operating temperature within the engine affects the

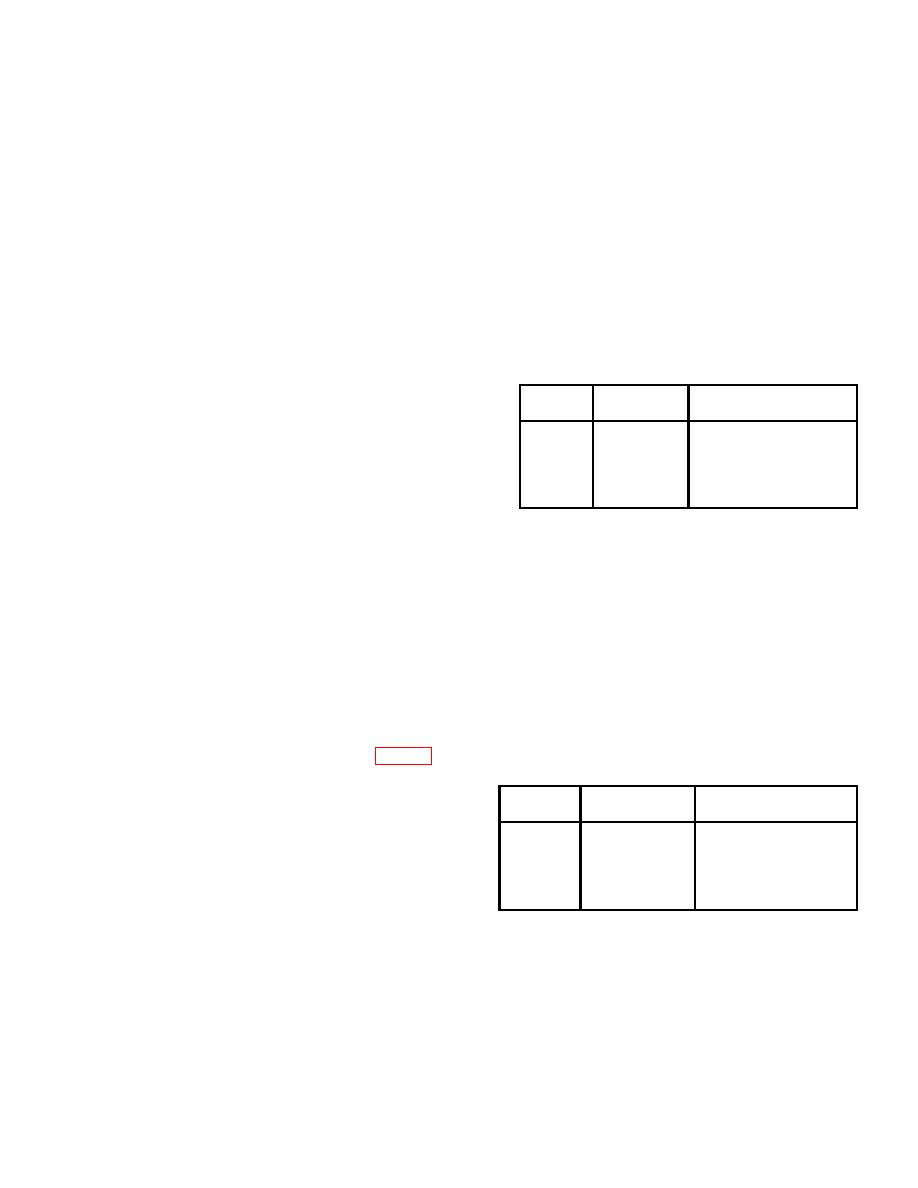

BASIC ENGINE RUN-IN SCHEDULE

operating clearances between the various moving parts

Speed

Time

of the engine and determines to a degree how the parts

(rpm)

(minutes)

Horsepower

will wear. Normal coolant temperature (160-185 or

F

1200

10

28

71-85 ) should be maintained throughout the Run-In.

C

1800

30

90

*1800

30

110

The rate of water circulation through the engine on a

*2100

30

118

dynamometer should be sufficient to avoid having the

*2300

30

128

engine outlet water temperature more than 100 higher

than the water inlet temperature. Though a 10 rise

*Run at only one of the speeds shown, whichever is at

across an engine is recommended, it has been found

or nearest to the governed speed and reset governor

that a 15 temperature rise maximum can be

after final run, if necessary.

permitted.

A thermostat is used in the engine to control the coolant

flow. Therefore, be sure it is in place and fully operative

or the engine will overheat during the Run-In. However,

if the dynamometer has a water standpipe with a

temperature control regulator, such as a Taylor valve or

equivalent, the engine should be tested without the

thermostat.

The Basic Engine Run-In Schedule is shown in Table 1.

FINAL ENGINE RUN-IN SCHEDULE

The horsepower shown is at SAE conditions: dry air

density .0705 lb/cu. ft. (1.129 Kg/m3), air temperature

Speed

Time

of 85 (29.4 ), and 500 ft. (152 m) elevation.

F

C

(rpm)

(minutes)

Horsepower

DYNAMOMETER TEST AND RUN-IN PROCEDURES

1200

10 (minimum)

28

2100

30

116

The Basic Engine

2100

30

130

2100

30

+

The great number of engine applications make any

+Within + 5% of rated bhp.

attempt to establish comparisons for each individual

model impractical. For this reason, each model has a

TABLE 1

basic engine rating for comparison purposes.

10-9-2