TM 5-3895-359-14&P

extending into the journal fillet. If main bearings are

circumferential fillet cracks at the critical areas and 45

replaced due to one or more badly damaged bearings, a

cracks (45 with the axis of the shaft) starting from

careful inspection must be made to determine if any

either the critical fillet locations or the connecting rod

cracks have started in the crankshaft. These cracks are

journal holes as shown in Fig. 5. Replace the

most likely to occur on either side of the damaged

crankshaft when cracks of this nature are found.

bearing.

Crankshaft Grinding

Torsional fatigue failures result from torsional vibration

which takes place at high frequency.

In addition to the standard size main and connecting rod

bearings, .002 ", .010", .020" and .030" undersize

A combination of abnormal speed and load conditions

bearings are available.

may cause the twisting forces to set up a vibration,

referred to as torsional vibration, which imposes high

NOTE:

stresses at the locations shown in Fig. 4.

The .002 " undersize bearings are

used only to compensate for slight

Torsional stresses may produce a fracture in either the

wear on crankshafts on which

connecting rod journal or the crank cheek. Connecting

regrinding is unnecessary.

rod journal failures are usually at the fillet at 45 to the

axis of the shaft.

If the crankshaft is to be reground, proceed as follows:

A loose, damaged or defective vibration damper, a

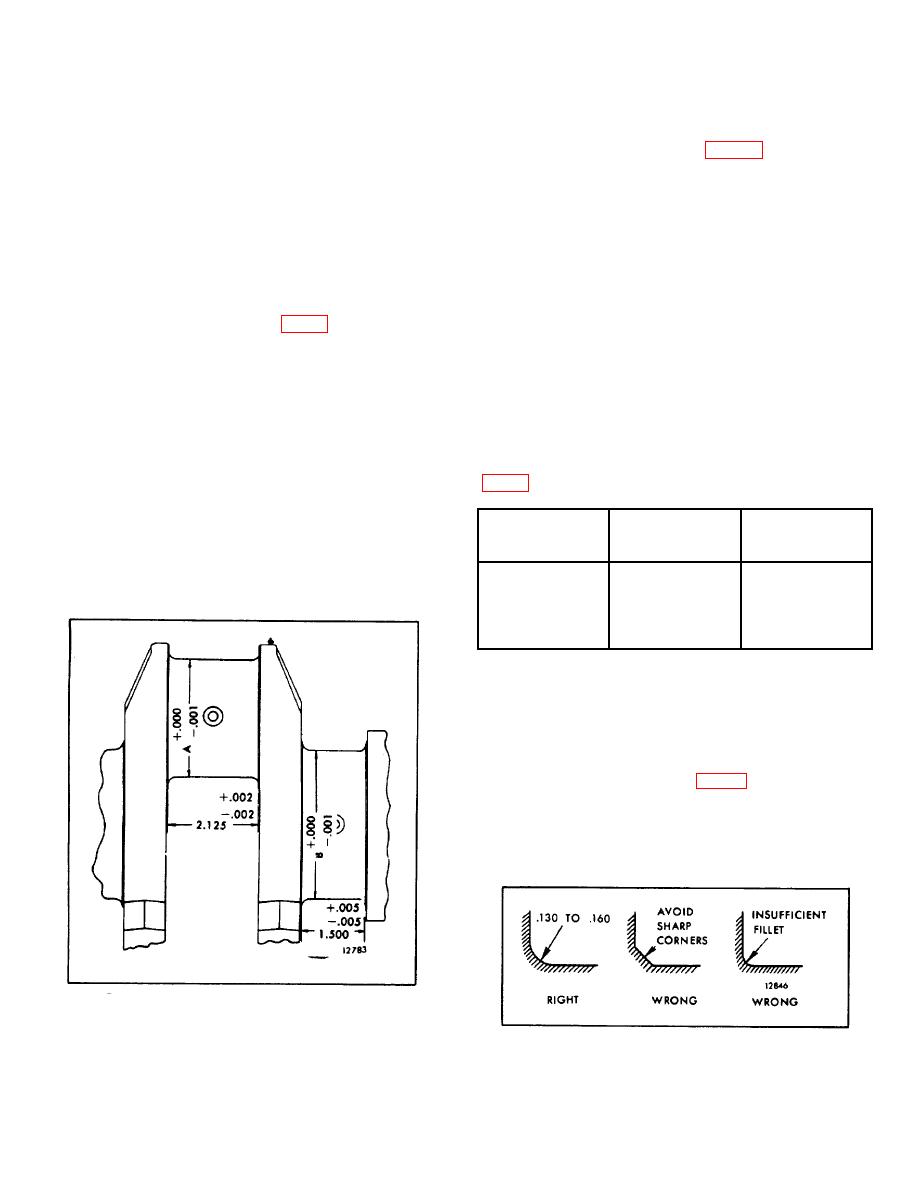

1. Compare the crankshaft journal measurements taken

loose flywheel or the introduction of improper or

during inspection with the dimensions in Table 2 and

type of failure. Also, overspeeding of the engine or

to be reground.

resetting the governor at a different speed than intended

Conn. Rod

Main Bearing

for the engine application may be contributory factors.

Bearing

Journal Dia.

Journal Dia.

Sizes

A

"B

As previously mentioned, most of the indications found

Standard

2.750"

3.500"

during inspection of the crankshaft are harmless. The

.002" Undersize

2.750"

3.500"

two types of indications to look for are

.010" Undersize

2.740"

3.490"

.020" Undersize

2.730"

3.480"

.030" Undersize

2.720"

3.470"

TABLE 2

2. If one or more main connecting rod journals require

grinding, then grind all of the main journals or all of the

connecting rod journals to the same required size.

3. All journal fillets must have a .130 " to .160 " radius

between the crank cheek and the journal and must not

have any sharp grind marks (Fig. 7). The fillet must

blend smoothly into the journal and the crank cheek and

must be free of scratches. The radius may be checked

with a fillet gage.

4. Care must be taken to avoid localized heating which

Fig. 6. Dimensions of Crankshaft Journals

Fig. 7. Crankshaft Journal Fillets.

10-2-52