TM 5-3895-359-14&P

rotating bearing in such a way that the rollers leave

impressions on the contact surfaces of the cones.

These impressions may not be easily discerned during

normal inspection. For example, a bearing may be

brinelled if a load were applied to the inner cone of the

bearing assembly in order to force the outer cone into

the idler gear bore, thus transmitting the force through

the bearing rollers. A brinelled bearing may have a very

short life.

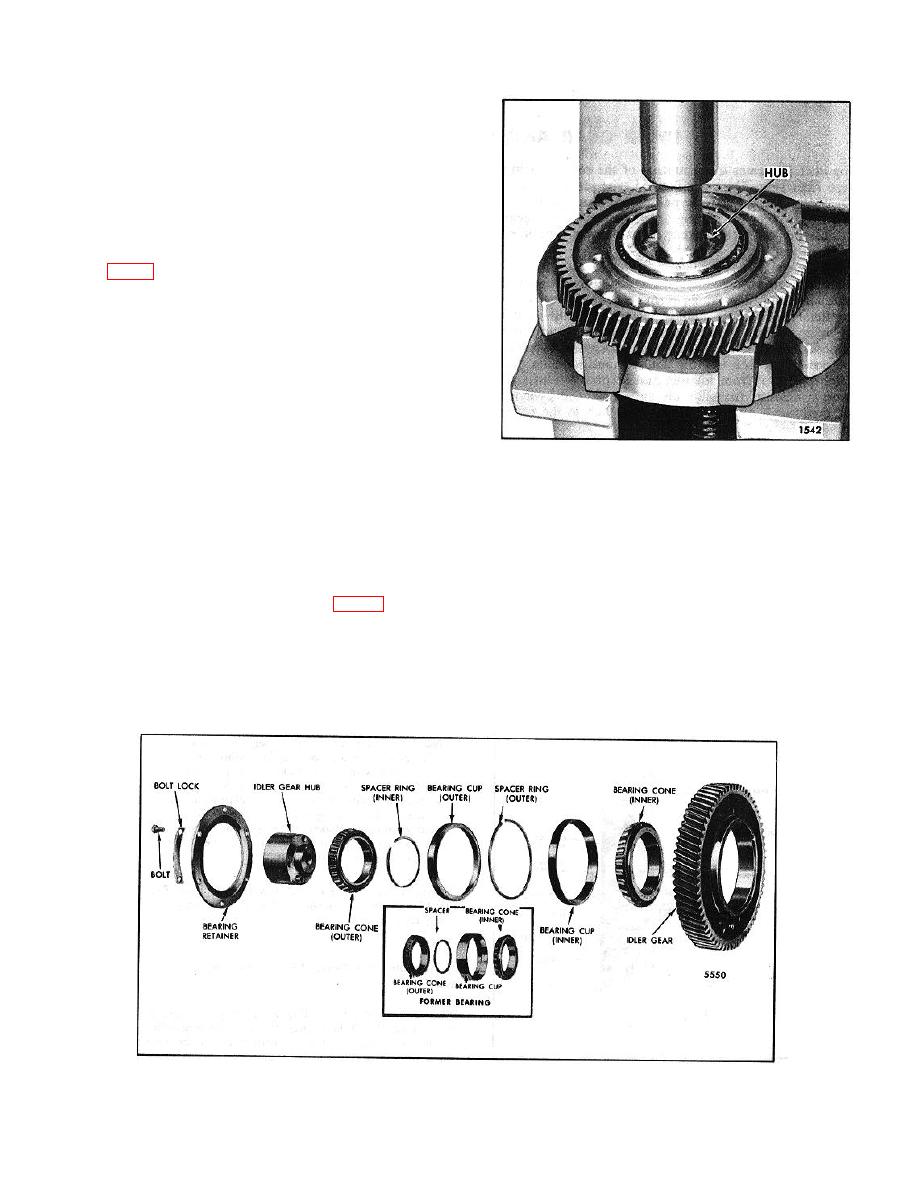

Refer to Fig. 3 for the location and identification of parts

and disassemble the bearing as follows:

1. Remove the six bolts and three bolt locks which

secure the bearing retainer to the idler gear, and remove

the bearing retainer.

NOTE:

The component parts of the idler

gear bearing are matched: therefore.

matchmark

the

parts

during

Fig. 2. Pressing Hub Out of Bearing

disassembly to ensure reassembly of

the parts in their original positions.

Inspection

2. Clean the idler gear and bearing assembly with fuel

Wash the idler gear, hub, and bearing components

oil and dry it with compressed air.

thoroughly in clean fuel oil and dry with compressed air.

3. Place the idler gear and bearing assembly in an

Check the idler gear hub and spacer.

arbor press with the bearing cone or inner race

supported on steel blocks as shown in Fig. 2. While

Inspect the bearings carefully for wear, pitting, scoring

rotating the gear assembly, press the hub out of the

or flat spots on the rollers or cones. Replace the

bearing. Remove the gear assembly from the arbor

bearing if it is defective.

press and remove the bearing cones and spacers.

4. Tap the bearing cups and spacer rings from the idler

gear by using a brass drift alternately at four notches

provided around the shoulder of the gear.

Fig. 3. Idler Gear Details and Relative Locating Parts (Current Bearing)

10-2-118