TM 5-3895-359-14&P

IDLER GEAR AND BEARING ASSEMBLY

spacer was used on early design bearings. The bearing

type idler gear. The early flanged type idler gear and

cup(s) has a light press fit in the idler gear and is held

the former single spacer type idler gear are no longer

against a flanged lip inside the idler gear on one side

serviced.

When replacing any part of the gear

and by a bearing retainer secured with six bolts and

assembly a complete current roller bearing type idler

three bolt locks on the other side.

gear assembly must be used.

A right-hand helix gear is provided for left-hand rotation

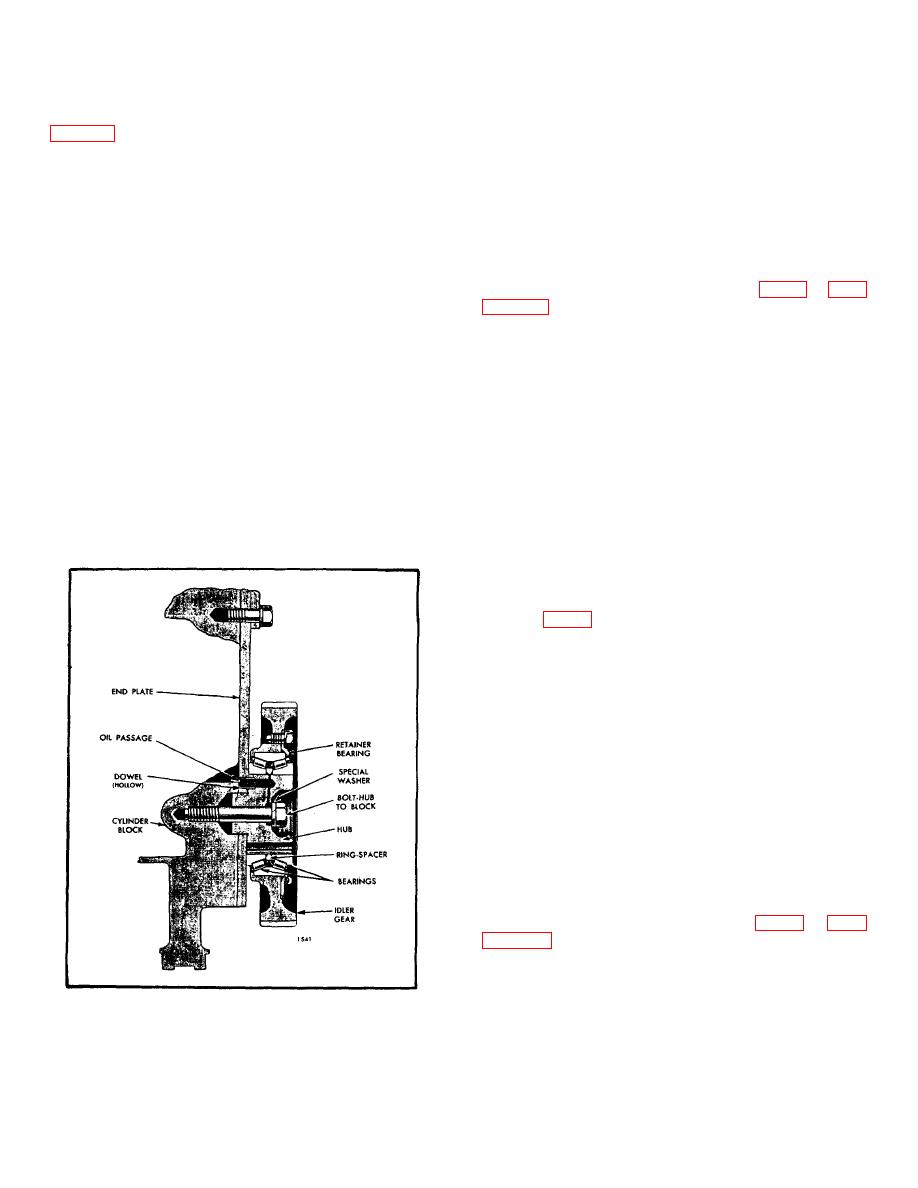

The idler gear is mounted on a double row, tapered

engines, and a left-hand helix gear is provided for right-

roller bearing which, in turn, is supported on a stationary

hand rotation engines. Since the engine is right hand

hub. This hub is secured directly to the cylinder block

by a bolt which passes through the hub and rear end

plate. A hollow dowel serves a two-fold purpose; first,

as a locating dowel it positions the hub and prevents it

An idler gear hole spacer (dummy hub) is used on the

from rotating and, second, conducts oil under pressure

side opposite the idler gear. NO gasket is used between

from an oil gallery in the cylinder block through a

the idler gear hub or dummy hub and the flywheel

passage in the gear hub to the roller bearing.

housing. The flywheel housing bears against the inner

races of the idler gear bearing and also against the

The current idler gear bearing consists of two cups, two

dummy hub. Three self-locking bolts and steel washers

cones and an outer and inner spacer ring. The former

are used to attach the flywheel housing at the idler gear

idler gear bearing consists of a cup, two cones and a

and dummy hub locations. The washers seat in 7/8"

spacer ring.

spot faces at the flywheel housing attaching bolt holes,

thus preventing oil leakage at these locations.

The inner and outer cones of the idler gear bearing are

pressed onto the gear hub and, therefore, do not rotate.

Remove Idler Gear, Hub and Bearing Assembly and

Spacer rings or a spacer, separate the cones. No

Idler Gear Hole Spacer (Flywheel Housing

Previously Removed)

1. Remove the idler gear hub to cylinder block bolt and

washer (Fig. 1) and withdraw the assembly from the

cylinder block rear end plate.

NOTE:

Before removing the idler gear check

the idler gear, hub and bearing

assembly for any perceptible wobble

or shake when pressure is applied;

by firmly grasping the rim of the gear

with both hands and rocking in

relation to the bearing. The bearing

must be replaced if the gear wobbles

or shakes. If the gear assembly is

satisfactory, it is only necessary to

check

the

pre-load

before

reinstallation,

completely reconditioned.

Disassemble Idler Gear, Hub and Bearing Assembly

Fig. 1. Idler Gear Mounting Typical

While removing or installing an idler gear bearing, the

bearing MUST be rotated to avoid the possibility of

damaging the bearing by brinelling the bearing cones.

Brinelling refers to the marking of the cones by applying

a heavy load through the rollers of a non-

10-2-117