TM 5-3895-359-14&P

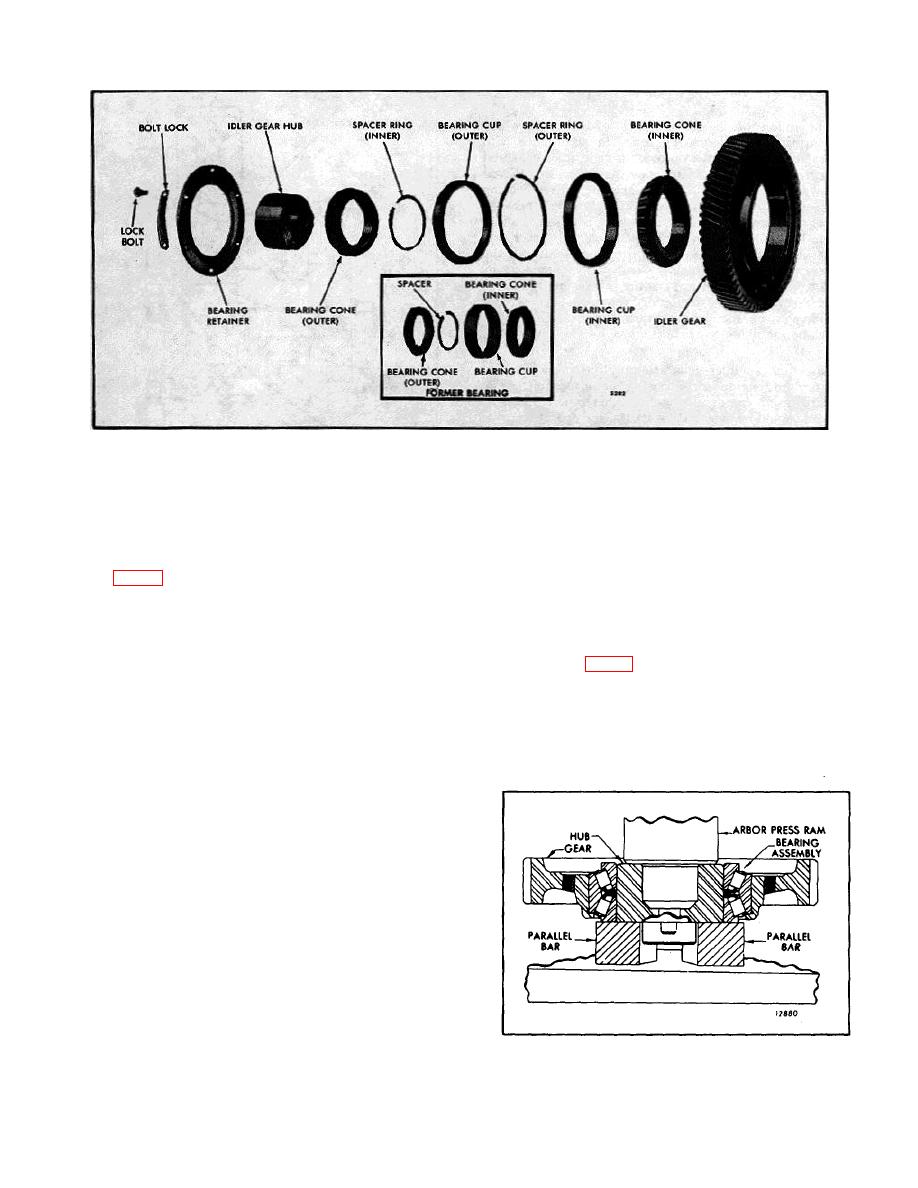

Fig. 4. Idler Gear Details and Relative Location of Parts

5.

Install the inner spacer ring on the idler gear hub

Examine the gear teeth for evidence of scoring, pitting

so that the oil hole in the hub is 180from the gap in the

and wear. If severely damaged or worn, replace the

inner spacer ring.

gear. Also, inspect the other gears in the gear train.

6.

Position the gear with both cups over the hub and

Assemble Idler Gear, Hub and Bearing

the inner bearing cone.

Refer to Fig. 4 and assemble the bearing components

7.

Press the outer idler gear bearing cone over the

in their original positions (refer to identification marks

hub while rotating the gear to seat the rollers properly

made during disassembly) as outlined below:

between the cones.

The bearing cones must be

supported so as not to load the bearing rollers during

NOTE:

The current idler gear

this operation (Fig. 5).

bearing is a matched assembly. Do

not mix components.

8.

Before installing the gear and bearing assembly,

check the pre-load.

1.

Support the idler gear, shoulder down, on the bed

of an arbor press. Start one of the bearing cups,

numbered side up, squarely into the bore of the gear.

Then press the bearing cup against the shoulder of the

gear. Use a flat steel plate (pre-load test plate) between

the ram of the press and the bearing cup.

2.

Lay the outer spacer ring on the face of the

bearing cup.

3.

Start the other bearing cup, numbered side down,

squarely into the bore of the gear. Then press the cup

tight against the spacer ring. Use a flat steel plate (pre-

load test plate) between the ram of the press and the

bearing cup.

4.

Press the inner bearing cone (numbered side up)

on the idler gear hub, flush with the inner hub mounting

face. Use the pre-load test plate (with the large center

Fig. 5. Pressing Hub into Bearing

hole) between the ram of the press and the bearing.

10-2-119