TM 5-3895-359-14&P

If the crankshaft and camshaft gears are mounted on

A scale reading which exceeds the specified maximum

the engine, a suitable fixture, which may be held in a

indicates binding of the bearing rollers, or rollers

vise, can be made as shown in Fig. 6. Three plates

improperly installed. When the scale reading is less

(shown in Fig. 7) a 1/2"-13 x 2 3/4" bolt and a plain

than the specified minimum, the bearing is more likely

washer are used with a 1/2 "-13 nut and plain washer for

worn and should be replaced.

mounting. One of the plates is used to take the place of

the flywheel housing, and the other two plates, the

After the pre-load test is completed, remove the steel

cylinder block, Engine-mounted conditions are simulated

plates and install the bearing retainer as follows:

by tightening the nut to 80-90 lb-ft (108-122 Nm) torque

and tightening the three plate-to-hub attaching bolts to

1.

Attach the bearing retainer to the idler gear with

25-40 lb-ft (34-54 Nm) torque.

six bolts and three bolt locks. Tighten the bolts to 24-29

lb-ft (33-39 Nm) torque.

Check the pre-load as follows:

IMPORTANT:

New locking bolts

1.

Attach the plates (two upper plate shown in Fig 7)

should always be used when

to the idler gear with 1/2"-13 bolt, washers and nuts as

attaching the bearing retainer to the

shown in Fig. 6. Tighten the bolt to 80-90 lb-ft (108122

idler gear.

Nm) torque.

2.

Bend the ears of each bolt lock against the flat

side of the attaching bolt heads to secure the bolts.

2.

Attach the third plate to the idler gear hub with

three 3/8 "-16 bolts. Tighten the bolts to 25-40 Ib-ft (34-

Install Idler Gear, Hub and Bearing Assembly

54 Nm) torque.

1.

Position the crankshaft gear and the balance shaft

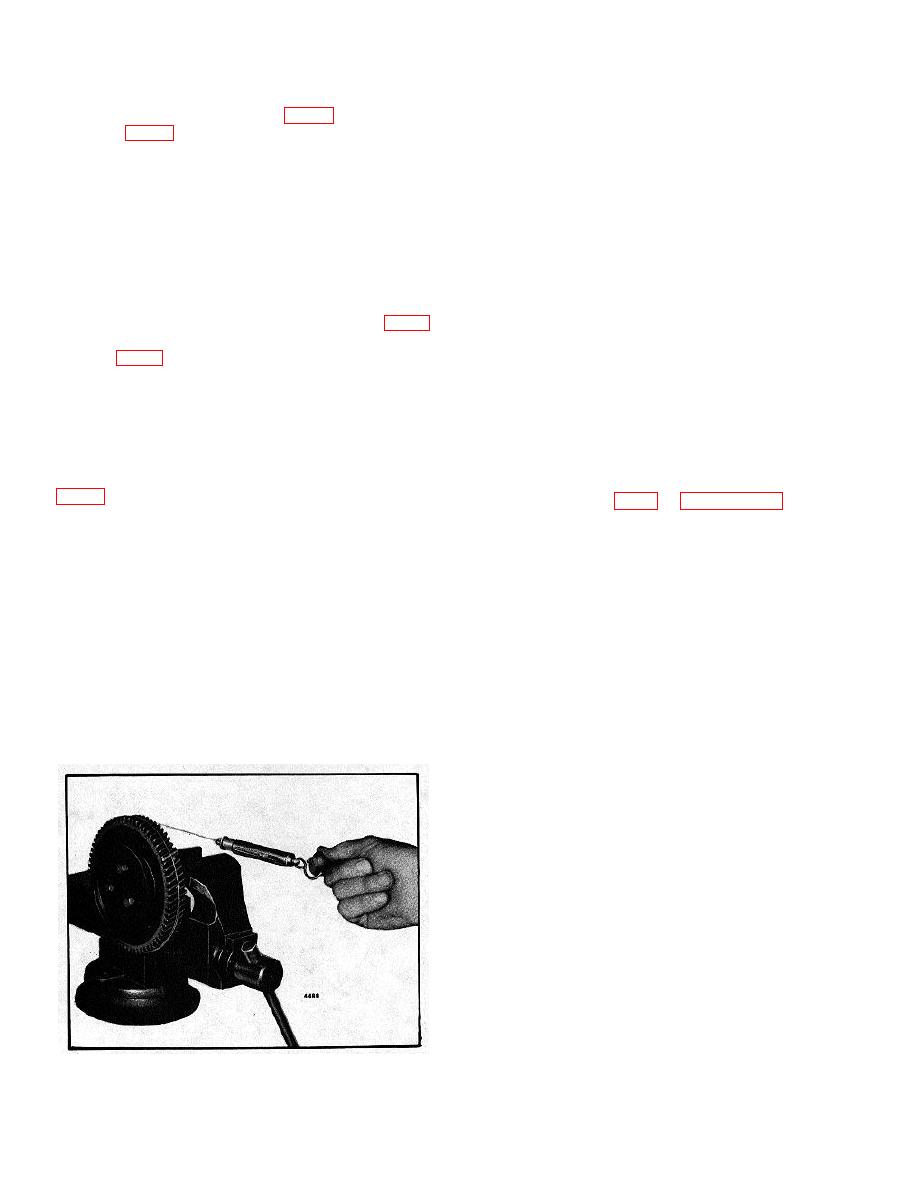

3.

Clamp the idler gear assembly and fixture in vise

gear so that the timing marks will align with those on the

idler gear (refer to Fig. 1 on Page 10-2-103).

4.

Attach the cord to the idler gear and spring scale

2.

With these marks in alignment, start the idler gear

and check the pre-load as outlined in step 4 of the

into mesh with the crankshaft gear and the balance shaft

previous method.

gear, and simultaneously rotate the gear hub so that the

hollow dowel at the inner face of the hub registers with

If the scale reading is within the specified 1/2 to 4 lbs.,

the oil hole in the end plate.

but fluctuates more than the permissible 2 lbs. 11

ounces, the idler gear and bearing assembly must NOT

3.

Roll the idler gear into position, align the hollow

be installed on the engine. Fluctuations in scale reading

dowel with the hole in the end plate, and gently tap the

may be caused by the cones or races not being

hub until it seals against the end plate. Thus the hollow

concentric to each other, damaged cones or races or

dowel in the hub will conduct oil through the end plate

rollers, or dirt or foreign material within the bearings. In

and into the hub where it flows through a drilled passage

these cases, the bearing should be inspected for the

to the roller bearing.

cause of fluctuation in the scale readings and corrected

or a new bearing installed.

4.

After making sure that the hub is tight against the

end plate, secure the idler gear assembly with a 1/2 "13

bolt and special washer. Tighten the bolt to 80-90 lb-ft

(108-122 Nm) torque.

5.

If previously removed, install the idler gear hole

spacer (dummy hub). Secure the spacer to the cylinder

block end plate and cylinder block with a 1/2 "-13 bolt

and special washer. Tighten the bolt to 80-90 lb-ft (108-

122 Nm) torque.

NOTE: Current engines use a new

idler gear hub and idler gear hole

spacer (dummy hub) which requires

1/2 "-13 x 2-1/2" retaining bolts,

replacing the 1/2"-13 x 2" bolts

formerly used.

6.

Lubricate the idler gear and bearing liberally with

Fig. 8. Checking Pre-Load of Idler Gear Bearing

clean engine oil.

10-2-121