TM 5-3895-359-14&P

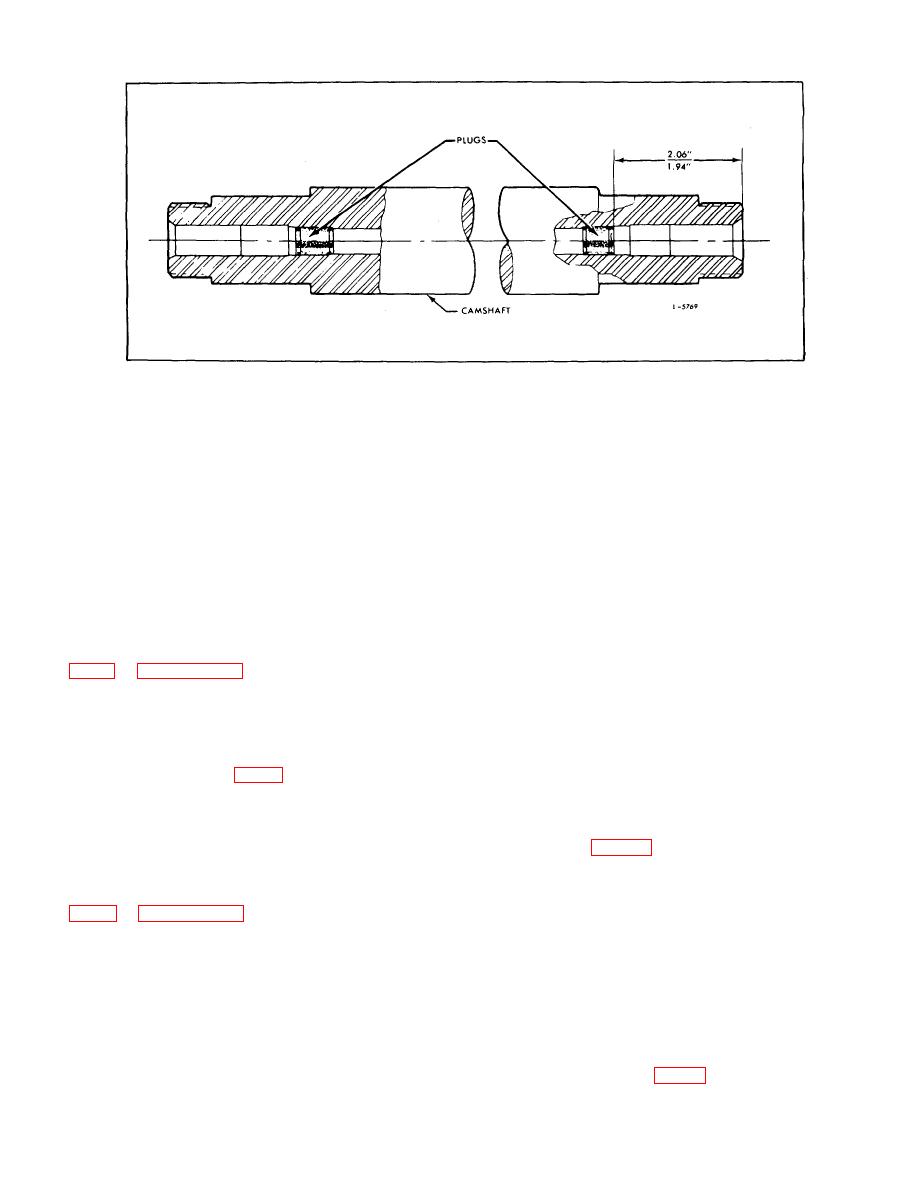

Fig. 12. Camshaft Plug Installation

8. Install the camshaft and balance shaft front end

Install Camshaft and Balance Shaft

bearings with the bolts and lock washers. Tighten the

bolts to 35-40 Ib-ft (47-54 Nm) torque.

1. Insert the front end of the camshaft into the opening

on the blower side of the engine. Push the camshaft

NOTE:

into the cylinder block until the camshaft gear teeth

almost engage the teeth of the mating gear. Use care

Install the front bearings with care to

when installing the camshaft to avoid damaging the cam

avoid dislodging the thrust washers.

lobes.

Do not hammer the bearings into the

cylinder block.

NOTE:

The right-hand gear (viewing the

9. Apply grease to the steel face of each thrust washer

engine from the flywheel end), has

and place them so that the steel faces are against the

left-hand helical teeth.

outer end of the camshaft and balance shaft front

bearings.

2. Align the timing marks on the mating gears as shown

10. Turn the camshaft intermediate bearings until the

in Fig. 1 on Page 10-2-103 and slide the camshaft gear

holes in the bearings are in alignment with the tapped

in place.

holes in the top of the cylinder block. Install the lock

screws and tighten them to 15-20 Ib-ft (20-27 Nm)

3. Secure the camshaft rear end bearing to the cylinder

torque.

block with the three bolts and lock washers. Rotate the

camshaft gear as required to install the bolts through

the hole in the gear web (Fig. 5). Tighten the bolts to

NOTE:

35-40 lb-ft (47-54 Nm) torque.

The current "high" cylinder blocks

incorporate longer lock screws than

4. Insert the balance shaft in the bore in the cylinder

were used formerly on the "low"

block and push it in until the teeth of the balance shaft

blocks (Fig. 13).

gear almost engage the camshaft gear teeth.

IMPORTANT:

5. Align the timing marks on the mating gears as shown

When the intermediate bearings are

in Fig. 1 on Page 10-2-103 and slide the balance shaft

locked into position with the

gear into place.

lockscrew, the bearing must have

slight movement in the block bore.

6. Secure the balance shaft rear end bearing. Use the

same procedure as outlined for the camshaft rear end

11. Install the front balance weights on the shafts.

bearing (Step 3).

12. Place an internal tooth lock washer on the end of

7. Apply grease to the steel face of each thrust washer.

each shaft and start the nuts on both shafts.

Then place a thrust washer against the inner end of the

camshaft and balance shaft front end bearing. The steel

13. Use a wood block (Fig. 4) between the balance

face of the thrust washer must be against the bearing.

weights or wedge a clean cloth between the camshaft

10-2-113