TM 5-3895-359-14&P

The non-turbocharged (naturally aspirated) engines use

an 18.7:1 compression ratio piston and the turbocharged

engines use a 17:1 compression ratio piston. To aid

identification of a piston, refer to Fig. 3. Fit the end of

the gage between the top of the piston crown and the

machined step below the third compression ring groove.

A "GO" check identifies a piston used in a turbocharged

engine. A space of approximately .030" ("NO-GO")

identifies a piston used in a naturally aspirated engine.

NOTE

Cross-head pistons and trunk-type

pistons must not be used together in

an engine. The difference in weight

of the pistons will affect engine

balance.

Inspect Piston Rings

When an engine is hard to start, runs rough or lacks

power, worn or sticking compression rings may be the

cause. Replacing the rings will aid in restoring engine

operation to normal.

The compression rings may be inspected through the

ports in the cylinder liners after the air box covers have

been removed. If the rings are free and are not worn to

the extent that the plating or grooves are gone,

compression should be within operating specifications.

Refer to Page 10-11-9 for the procedure for checking

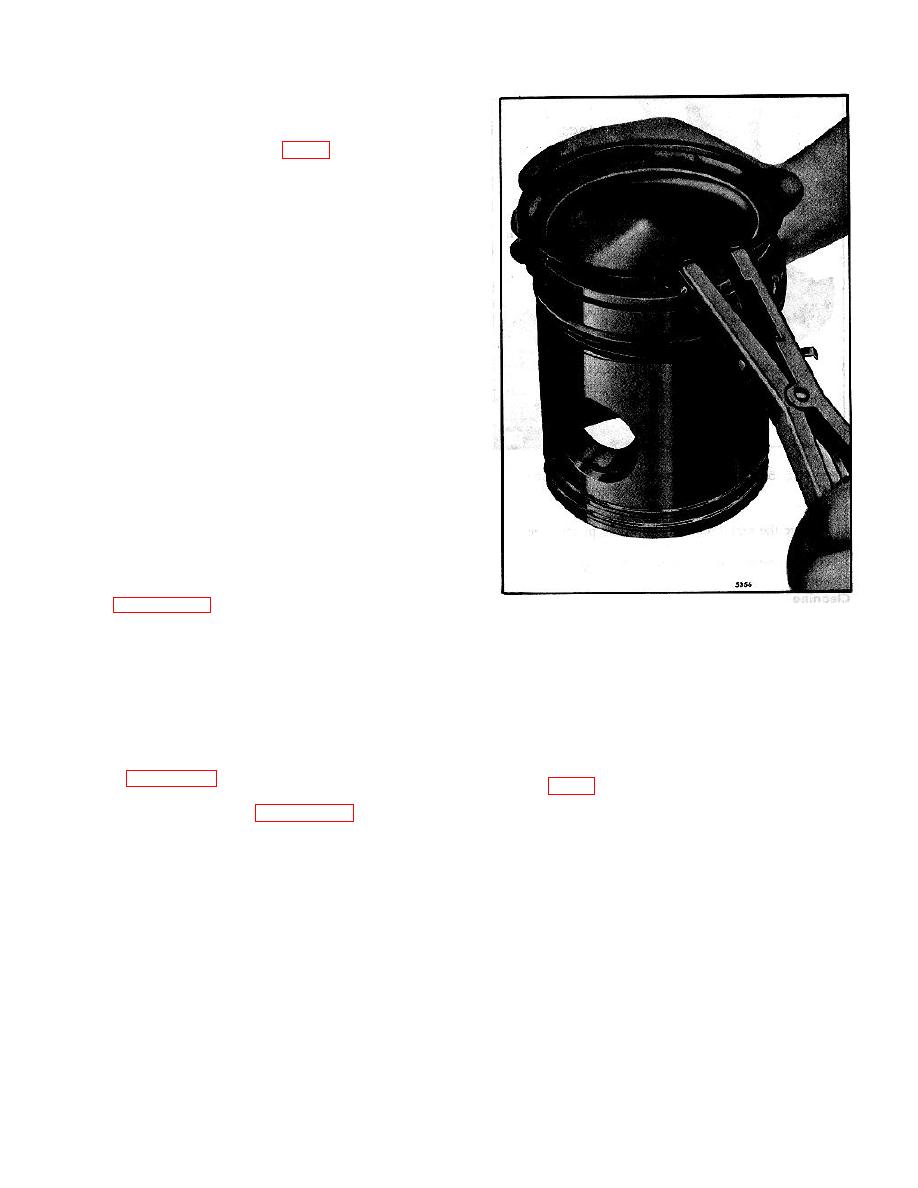

Fig. 4. Removing or Installing Piston Rings using

compression pressure.

Tool J 8128

Remove Piston and Connecting Rod

Disassemble Piston and Connecting Rod

1. Drain the cooling system.

Note the condition of the piston and rings. Then remove

the rings and disassemble the piston as follows:

2. Drain the oil and remove the oil pan.

1. Secure the connecting rod in a vise equipped with

3. Remove the oil pump and inlet and outlet pipes, if

soft jaws and remove the piston rings with tool J 8128 as

necessary (Page 10-5-6).

shown in Fig. 4.

2. Punch a hole through the center of one of the piston

4. Remove the cylinder head (Page 10-2-20).

pin retainers with a narrow chisel or punch and pry the

retainer from the piston, being careful not to damage the

5. Remove the carbon deposits from the upper inner

piston or bushing. Remove the opposite retainer in the

surface of the cylinder liner.

same manner.

3. Loosen the two bolts which secure the connecting rod

6. Remove the bearing cap and the lower bearing shell

to the piston pin. Then remove the rod and piston

from the connecting rod. Then push the piston and rod

assembly from the vise and place the assembly on the

assembly out through the top of the cylinder block. The

bench. Remove the two bolts and spacers and remove

piston cannot be removed from the bottom of the

the connecting rod.

cylinder block.

4. Withdraw the piston pin.

5. Separate the piston skirt from the piston crown.

7. Reassemble the bearing cap and lower bearing shell

to the connecting rod.

10-2-79