TM 5-3895-359-14&P

COMPRFSSION RINGS

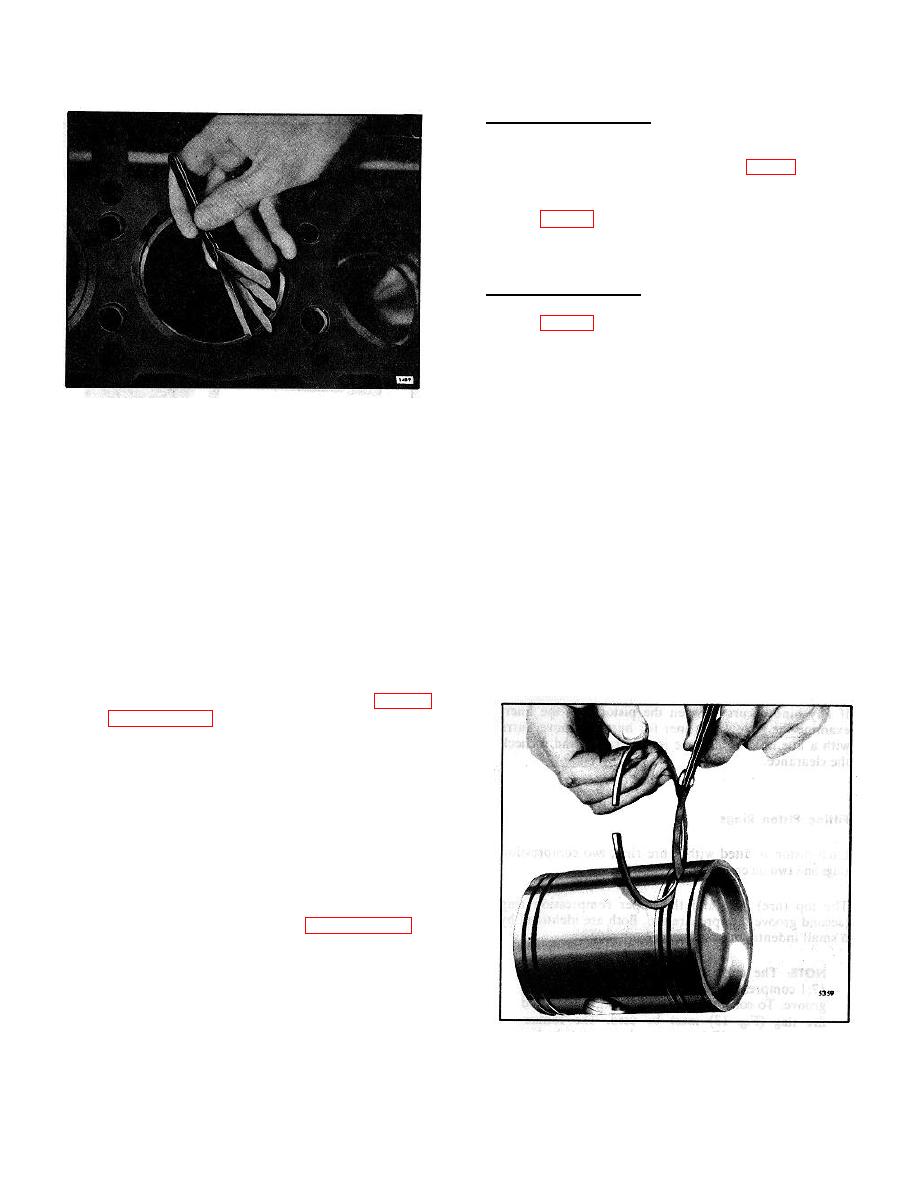

1. Starting with the bottom ring, install the compression

rings with tool J 8128 as shown in Fig. 4. To avoid

breaking or overstressing the rings, do not spread them

any more than necessary to slip them over the piston.

Refer to Fig. 16 for ring identification and location.

2. Stagger and ring gaps around the piston.

OIL CONTROL RINGS

Refer to Fig. 16 for the type and location and install the

oil control rings as follows:

1. Install the ring expanders in the oil control ring

grooves in the piston skirt. When installing the oil

control rings, use care to prevent overlapping the ends

of ring expanders. An overlapped expander will cause

Fig. 14 - Measuring Piston Ring Gap

the oil ring to protrude beyond allowable limits and will

result in breakage when the piston is inserted in the ring

A two-piece oil control ring is used in both oil ring

compressor during installation in the cylinder liner. Do

grooves in the pistons for all current engines with N75 or

not cut or grind the ends of the expanders to prevent

below injectors.

overlapping. Cutting or grinding the ends will decrease

the expanding force on the oil control rings and result in

All new piston rings must be installed whenever a piston

high lubricating oil consumption.

is removed, regardless of whether a new or used piston

or cylinder liner is installed. Refer to the parts catalog or

microfiche to select the current piston rings for a

expanders are used, install them with the legs of

particular engine.

the free ends toward the top of the piston. With

the free ends pointing up, a noticeable

Insert one ring at a time inside of the cylinder liner and

resistance will be encountered during installation

far enough down to be within the normal area of ring

of the piston if the ends of the expander are

travel. Use a piston skirt to push the ring down to be

over-lapped and corrective action can be taken

sure it is parallel with the top of the liner. Then measure

before ring breakage occurs.

the ring gap with a feeler gage as shown in Fig. 14.

Refer to Page 10-2-134 for ring gap specifications.

If the gap on a compression ring is insufficient. it may

be increased by filing or stoning the ends of the ring.

File or stone both ends of the ring so the cutting action

is from the outer surface to the inner surface. This will

prevent any chipping or peeling of the chrome plate on

the ring. The ends of the ring must remain square and

the chamfer on the outer edge must be approximately

.015".

Check the ring side clearance as shown in Fig. 15.

Ring side clearances are specified on Page 10-2-134.

Install Piston Rings

NOTE: Lubricate the piston rings and piston

Fig. 15 Measuring Piston Ring Side Clearance

with engine oil before installing the rings.

10-2-84