TM 5-3895-359-14&P

Examine the piston skirt and crown for score marks,

The bearing must be installed before

cracks, damaged ring groove lands or indications of

assembling the piston skirt and

overheating. Any piston that has been severely scored

crown.

or overheated must be replaced.

Indications of

2. Lubricate the metal seal ring (Fig. 6) with engine oil

overheating or burned spots may be the result of an

and install it with the chamfer or counterbore directed

obstruction in the connecting rod oil passage.

toward the bottom of the piston.

NOTE

Check the tapered fire ring groove width in the current

The current seal rings are made of

piston crown with tool J 24599 as shown in Fig. 5 Slide

cast iron and are identified by the tin-

the "NO-GO" wire (.106" diameter) of the tool

plating on the outside diameter, a

completely around the fire ring groove. Should the wire

black oxide finish, or a dull cast iron

be below flush at any one area, the piston crown must

color. These rings can be mixed in

be replaced. The "GO" wire (.100" diameter) should be

an engine. The former steel ring,

flush or protrude slightly from the fire ring groove.

identified

by

a

very

shiny

appearance, must not be used for

Check the cylinder liner and block bore for excessive

service.

out-of-round, taper or high spots which could cause

3. Compress the seal ring with ring compressor J 23453

failure of the piston (refer to Page 10-2-133 for

and push the skirt into position on the piston crown.

specifications.)

NOTE

Before completely assembling the

Inspection of the connecting rod, piston pin and piston

piston, check to make sure the seal

pin bushing are covered on Page 10-2-86.

ring does not stick in the ring

groove.

It is imperative for

Other factors that may contribute to piston failure

satisfactory engine operation that the

include oil leakage into the air box, oil pull-over from the

seal ring is free in the piston crown

air cleaner, dribbling injectors, combustion blow-by and

groove.

Check the full 360

low oil pressure (dilution of the lubricating oil).

circumference of the groove to be

sure there are no tight spots. When

the piston crown, seal ring and

piston skirt are assembled, the skirt

should spin freely on the crown

(crown top down on the bench). If

the seal ring sticks, remove high

spots or nicks in the groove with a

flat file. If this does not relieve

sticking, replace the piston crown.

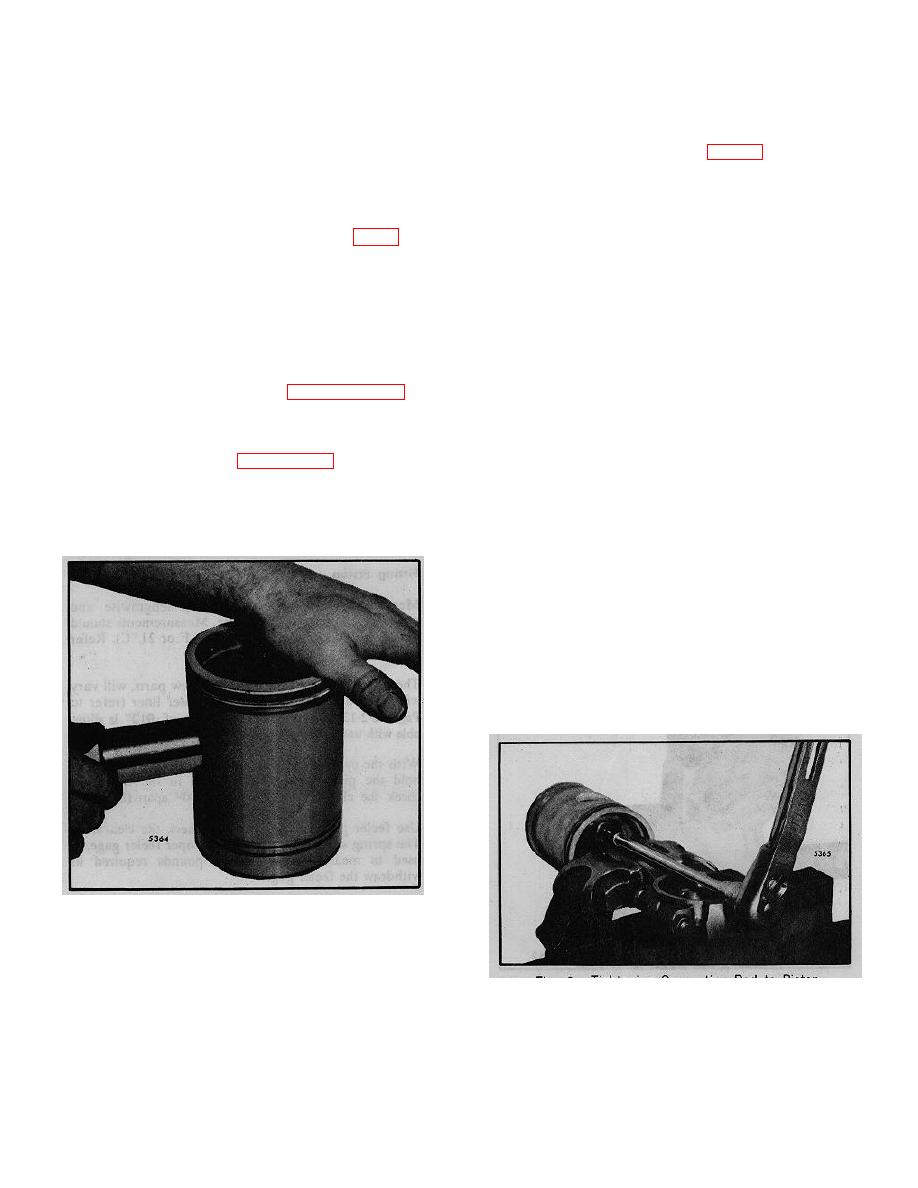

Fig. 7. Installing Piston Pin

Assemble Piston

1. Install the bearing (bushing) in the piston crown. It

should slide into the piston crown without force. With

Fig. 8. Tightening Connecting Rod to Piston Pin

new parts, there is .0005" to .0105" clearance between

Bolts

the edge of the bushing and the groove in the piston

crown.

NOTE

10-2-81