TM 5-3895-359-14&P

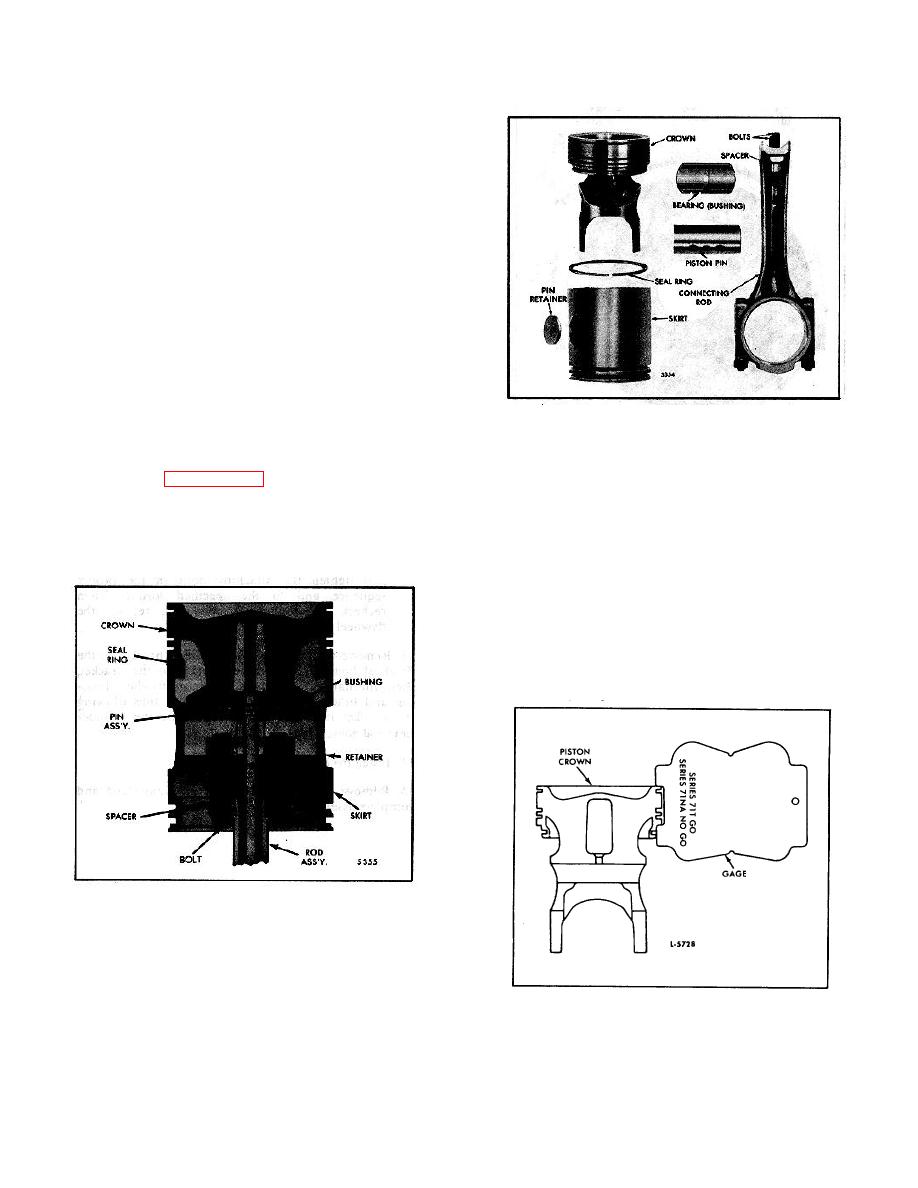

CROSS-HEAD TYPE PISTON

The cross-head piston (Figs. I and 2) is a two-piece

piston consisting of a crown and skirt. A metal oil seal

ring is used between the crown and skirt which are held

together by the piston pin. Ring grooves are machined

in the piston crown for a fire ring and two compression

rings. The crown is also machined to accept a

150 lipper type bushing (bearing). The piston skirt

s

incorporates two oil control ring grooves, piston pin

holes and piston pin retainer counterbores. Equally

spaced drain holes are located in the oil ring groove

area to permit excess oil, scraped from the cylinder

walls, to return to the crankcase. A lubricating oil tube

and floating nut are contained inside of the piston pin.

Two bolts and spacers are used to attach the connecting

rod to the floating nut in the piston pin.

Detroit Diesel engines are designed to operate on diesel

fuels containing less than 0.5% sulfur. Plasma-faced

fire rings may be used in areas where approved fuel is

Fig. 2. Cross-Head Piston and Connecting Rod

not commercially available or economically feasible to

Components

obtain. It should be recognized that even with the use of

Internal parts of the piston are lubricated and cooled by

the high sulfur fuel modification and maintenance

the engine lubricating oil. Oil is pressure-fed up the

procedures (see Page 10-9-7), engine life may still not

drilled passage in the connecting rod. through the oil

equal that with our recommended fuels.

tube in the piston pin. then through the center hole in

NOTE

the bushing to the underside of the piston crown. A

Recommended engine modifications

portion of the oil flows along the grooves in the bushing

do not apply to U.S.

certified

to lubricate the piston pin.

automotive engines.

During engine operation, gas loads pushing down on the

piston crown are taken directly by the piston pin and

bushing. The piston skirt, being separate, is free from

vertical load distortion; thermal distortion is also reduced

as the piston crown expands. As the connecting rod

swings to one side during downward travel of the piston,

the major portion of the side load is taken by the piston

skirt.

Fig. 1. Cross-Head Piston and Connecting Rod

Assembly

Fig. 3. Piston Identification using Gage J 25397

10-2-78