TM 5-3895-359-14&P

sealed with synthetic rubber seal rings which fit into

counterbored holes in the block. A synthetic rubber seal

fits into a milled groove near the perimeter of the block.

When the cylinder head is drawn down, a positive

leakproof metal-to-metal contact is assured between the

head and the block.

NOTE: Production non-turbocharged

cylinder heads include cast steel

exhaust valve seat inserts which have

magnetic qualities. An easy method for

determining the type of exhaust valve

seat insert in a cylinder head is with a

magnet. The magnet will be attracted

to the non-turbo insert (will stick). The

magnet will not be attracted to the turbo

insert, it will jump to the cylinder head.

Cylinder Head Maintenance

The engine operating temperature should be maintained

between 160-185 (71-85 ) and the cooling system

F

C

should be inspected daily and kept full at all times. The

cylinder head fire deck will overheat and crack in a short

time if the coolant does not cover the fire deck surface.

When necessary, add coolant slowly to a hot engine to

avoid rapid cooling which can result in distortion and

cracking of the cylinder head (and cylinder block).

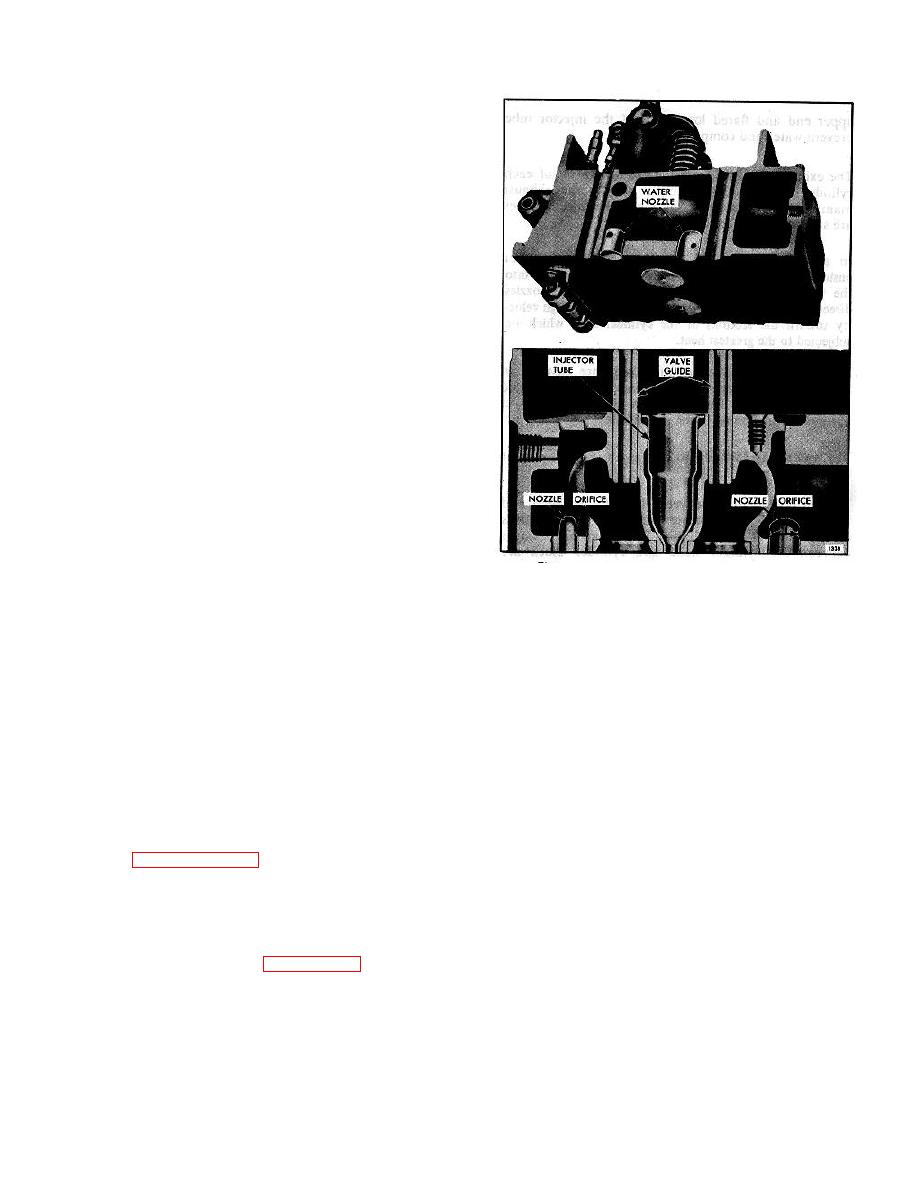

Fig. 4. Water Nozzle in Two-Valve Cylinder Head

Abnormal operating conditions or neglect of certain

Other conditions which may eventually result in cylinder

maintenance items may cause cracks to develop in the

head cracks are:

cylinder head. If this type of failure occurs, a careful

inspection should be made to find the cause and avoid a

1. Excess fuel in the cylinders caused by leaking

recurrence of the failure.

injectors.

Unsuitable water in the cooling system may result in

2. Slipping fan belts can cause overheating by reducing

lime and scale formation and prevent proper cooling.

air flow through the radiator.

The cylinder head should be inspected around the

exhaust valve water jackets. This can be done by

3. Accumulation of dirt on the radiator core which will

removing an injector tube. Where inspection discloses

reduce the flow of air and slow the transfer of heat from

such deposits, use a reliable non-corrosive scale

the coolant to the air.

remover to remove the deposits from the cooling system

of the engine, since a similar condition will exist in the

4. Inoperative radiator cap which will result in loss of

cylinder block and other components of the engine.

coolant.

Refer to Page 10-9-13 for engine coolant

recommendations.

Remove Cylinder Head

Loose or improperly seated injector tubes may result in

Certain service operations on the engine require

compression leaks into the cooling system and also

removal of the cylinder head:

result in loss of engine coolant. The tubes must be tight

to be properly seated. Refer to Page 10-3-25.

1. Remove and install pistons.

Overtightened injector clamp bolts may also cause head

2. Remove and install cylinder liners.

cracks. Always use a torque wrench to tighten the bolts

to the specified torque.

10-2-20