TM 5-3895-359-14&P

It is very important that all old gasket material be

and idler gear hole spacer, finger tight.

Remove the

pilot studs.

thoroughly removed from the flywheel housing and the

endplate, otherwise runout of the pilot and the face of

A self-locking type bolt and steel washer are currently

the housing may be affected when the housing is

being used to attach the flywheel housing to the idler

installed on the engine.

gear hub and hole spacer. With this type bolt, the

additional operation of securing the bolts with a lock wire

Remove and discard the crankshaft rear oil seal. Install

is eliminated, inasmuch as the head of the bolt is so

a new oil seal as outlined on Page 10-2-56.

designed that it will lock itself to the attaching member

when the specified torque is applied.

Install Flywheel Housing

NOTE

1. Lubricate the gear train teeth with clean engine oil.

2. Affix a new housing-to-end plate gasket to the

The self-locking bolts must be used

flywheel housing.

in sets of three.

3. Coat the lip of the oil seal lightly with engine oil. Do

not scratch or nick the sealing edge of the oil seal.

7. Install the six 1/2 "-13 housing to block bolts with

4. Thread four pilot studs J 1927-01 into the cylinder

lockwashers, finger tight.

block to guide the housing in place (Fig. 2). Use oil

8. Install the remaining flywheel housing attaching bolts

seal expander J 22425 (standard size seal) or expander

and washers, finger tight.

J 4195-01 and handle J 8092 (oversize seal) on the end

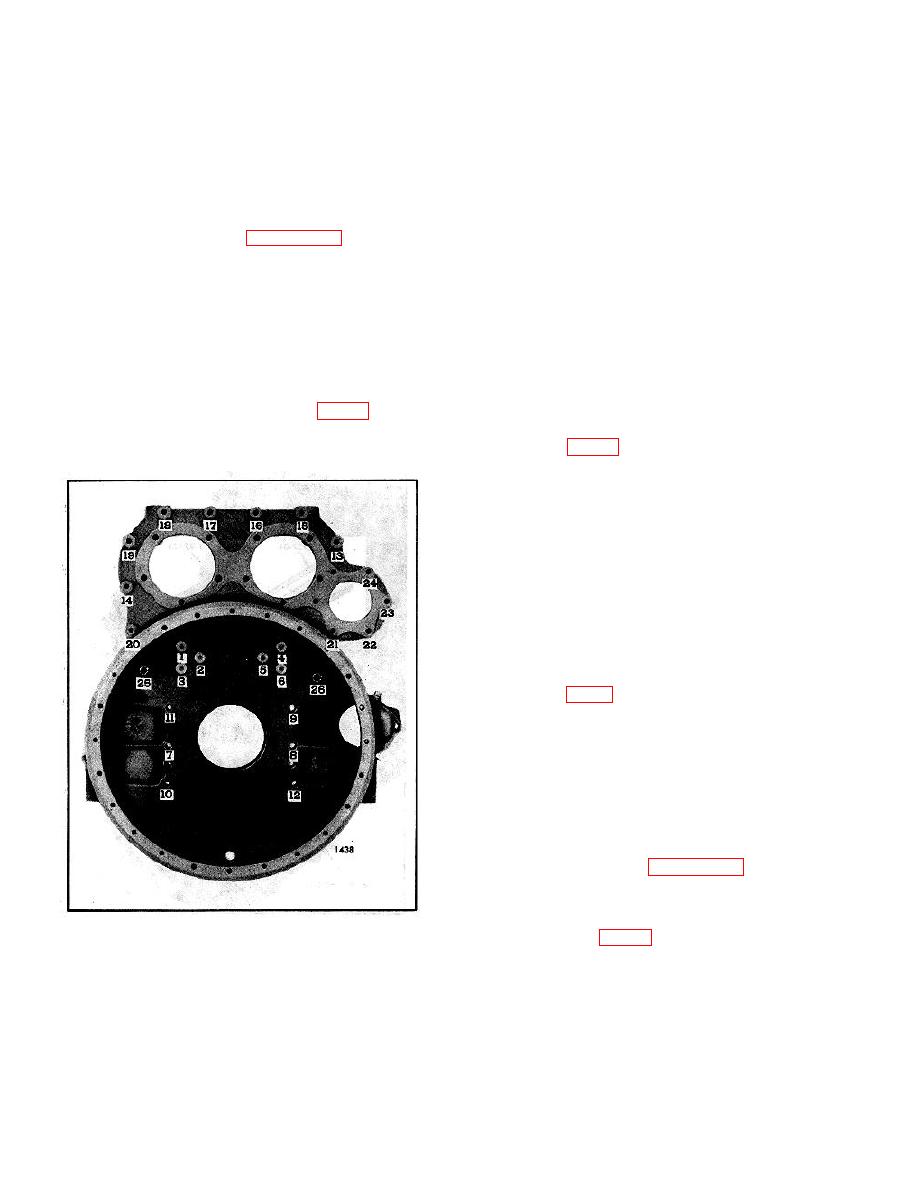

9. Refer to Fig. 3 for the bolt tightening sequence.

of the crankshaft to pilot the oil seal on the crankshaft.

Start at number I and, using the proper sequence, bring

all bolts to within 10-15 lb-ft (14.20 Nm) of their

specified torque, drawing the mating parts together

evenly.

NOTE

When tightening the idler gear hub

bolts, turn the crankshaft to prevent

any bind or brinelling of the idler

gear bearing. The crankshaft must

be rotated for the flywheel housing

bell tightening also.

10. Refer to Fig. 4 for the final bolt tightening sequence

and, starting at number 1, tighten all of the bolts to the

specified torque. Tighten the 3/8 "-16 idler gear hub and

hole spacer self-locking bolts to 40-45 lb-ft (54-61 Nm)

torque. Tighten all other 3/8 "-16 and 3/8 "-24 bolts to

25-30 lb-ft (34-41 Nm) torque, and the 1/2 "-13 bolts to

90-100 lb-ft (122-136 Nm) torque. Be sure to rotate the

crankshaft when tightening the idler gear hub bolts and

flywheel housing bell.

11. Install the flywheel (Page 10-2-72).

12. Check the flywheel housing concentricity and

bolting flange face with tool set J 9737-01 as follows:

Fig. 3. Flywheel Housing Bolt Tightening Sequence

a. Refer to Fig. 5 and thread the base post J

(Operation 1)

9737-3 tightly into one of the tapped holes in the

5. With the housing suitably supported, position it over

flywheel. Then assemble the dial indicators on

the crankshaft and up against the cylinder block rear

the base post.

end plate and gasket. Remove the oil seal expander.

6. Refer to Fig. I and install the six 3/8 "-16 bolts with

flat washers in the tapped holes of the idler gear hub

10-2-76