TM 5-3895-359-14&P

2.

Take out the drive coupling bolts (72) and remove

Remove Blower Drive Gear and Support

the retainer (71) and coupling support (67), see Fig. 5.

Assembly (Flywheel Housing Removed)

3.

Remove the drive gear hub nut (57), lock washer

Removal of the flywheel housing is not necessary when

(58), lock ball (55) and thrust washer (56) and withdraw

removing the blower drive gear, however, an inspection

the blower drive gear hub.

of the gear train is advisable when any one of the gears

requires service. The procedures for the removal of the

4.

Remove the thrust washer (Fig.

2) from the

flywheel and flywheel housing are found on Pages 10-2-

blower drive gear hub.

71 and 10-2-75.

5.

Press the gear hub out of the blower drive gear.

Before removing the blower drive gear, the blower drive

shaft must be removed as previously outlined.

Inspection

1.

Remove the blower as outlined on Page 10-4-9.

Clean the parts with fuel oil and dry them with

compressed air. Ensure that the oil grooves, oil holes,

2.

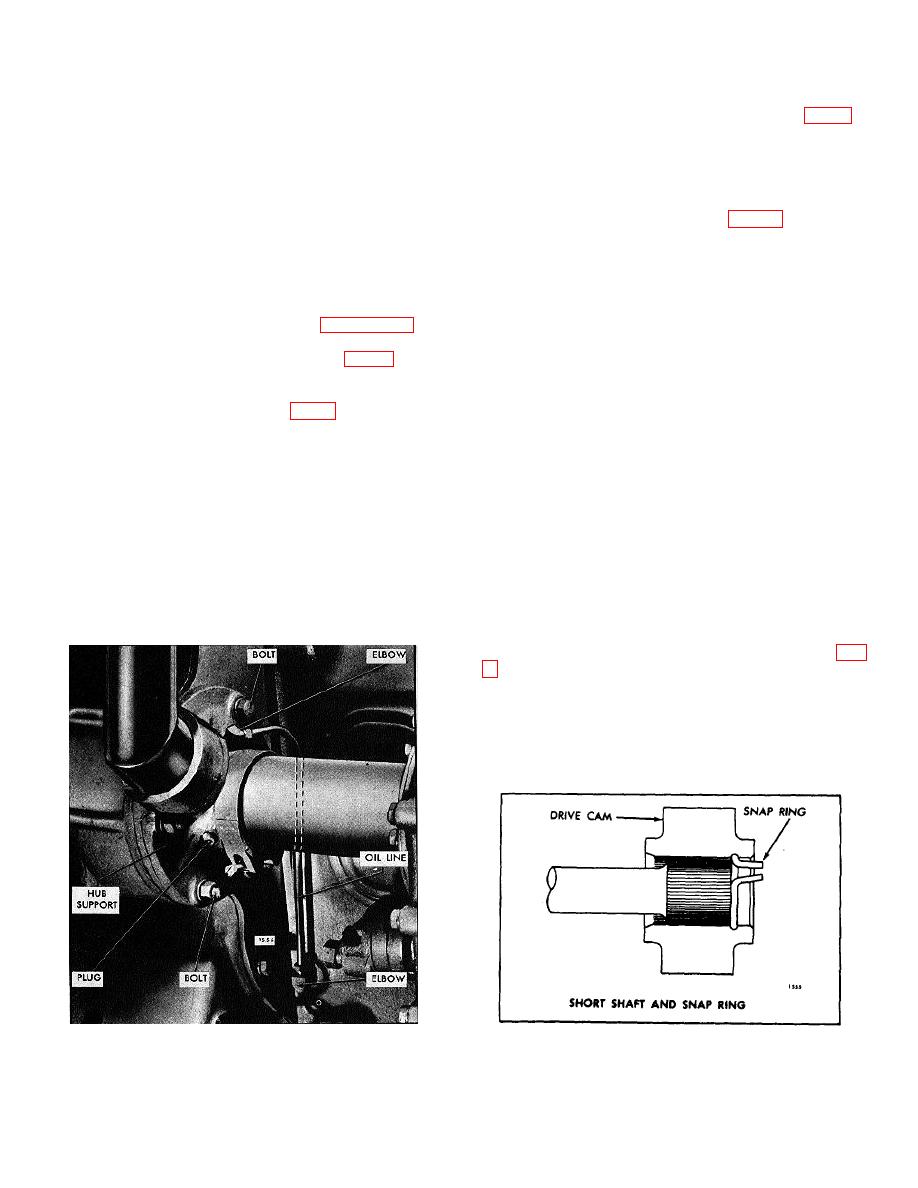

Remove the blower drive oil line, see Fig. 3.

and cavities are free of dirt.

3.

Straighten the ears on the lock washer (58) and

Replace the thrust washers if they are worn or scored.

loosen the drive gear hub nut (57), Fig. 5.

If the bearings are worn or scored excessively the drive

4.

Remove the blower drive support attaching bolts.

gear hub support or bearings will have to be replaced.

These bushing type bearings are diamond bored to an

5.

Loosen the blower drive support by tapping it

inside diameter of 1.6260" to 1.6265", after installation

lightly and withdraw the support from the cylinder block

in the hub.

rear end plate. Take care to prevent damage to the

blower drive gear teeth. Discard the gasket.

The clearance between the bearings and the hub is

.0010" to .0025" with new parts and a maximum of

Disassemble

Blower

Drive

Gear

and

Support

.0050" with used parts.

Assembly

The current bearing on the gear end protrudes .045" to

1.

Secure the blower drive gear and support

.055" above the surface of the face to facilitate the

assembly in a vise with soft jaws.

installation of the blower drive thrust washer (102) Fig.

.030" below the surface of the face of the support. Each

of the former bearings were flanged. Replacement

bearings must withstand a 2000 lb end load without

moving, also the bearing bores must be square with the

inner and outer faces of the support within .001" total

indicator reading.

Fig. 3. Blower Drive Gear and Support Assembly

Fig. 4. Bower Drive Shaft Mounting

Mounting

10-2-125