TM 5-3895-359-14&P

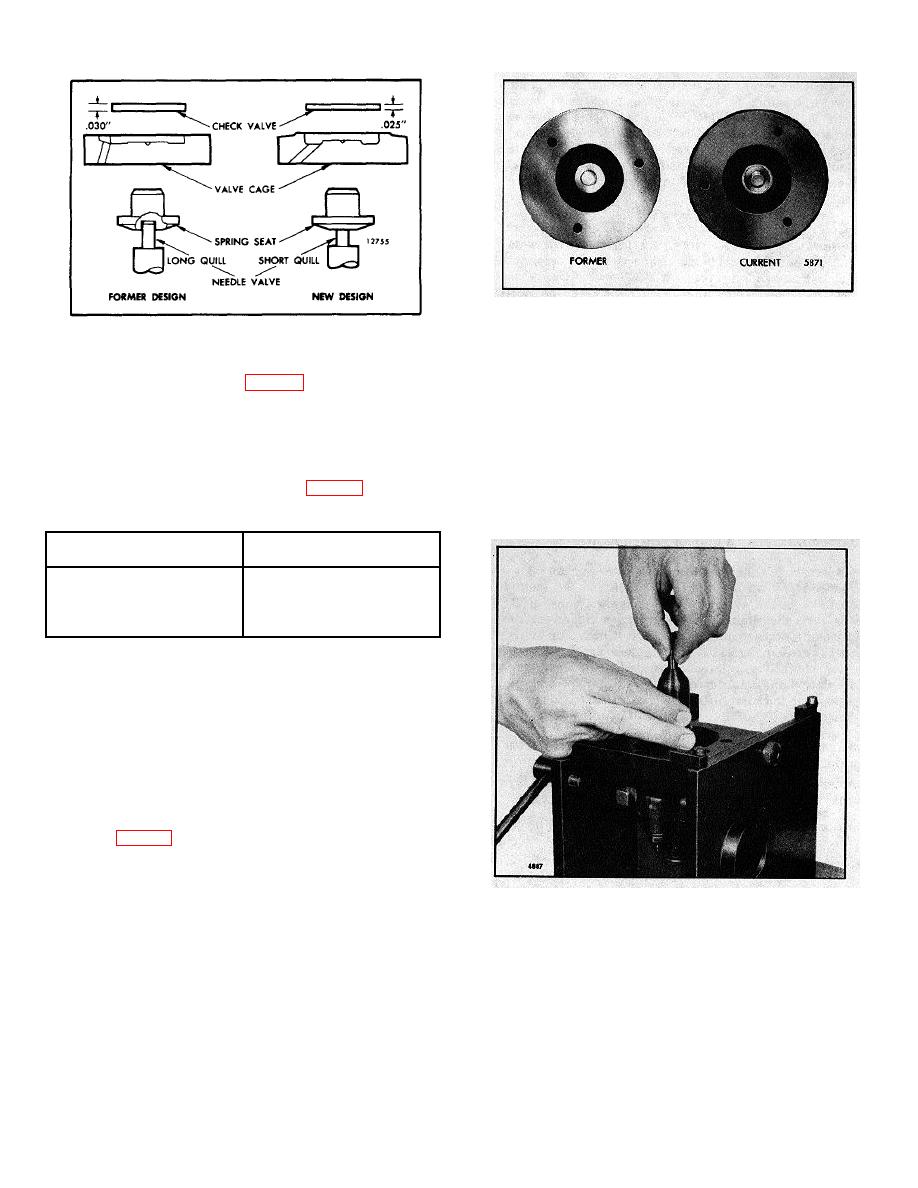

Fig. 39. Spray Tip Sealing Surface Identification

Fig. 38. Comparison of Former and New Design

5. When the part is flat, wash it in cleaning solvent and

Injector Parts

dry it with compressed air.

bright and shinny (Fig. 39). It is not

6. Place the dry part on the second block. After

recommended to lap the surface of

applying lapping powder, move the part lightly across

the new current spray tip.

the block in a figure eight motion several times to give it

a smooth finish. Do not lap excessively. Again wash

Lapping Injector Parts

the part in cleaning solvent and dry it with compressed

air.

Lap the sealing surfaces indicated in Fig. 31 and Table

I as follows:

7. Place the dry part on the third block. Do not use

lapping powder on this block. Keep the part flat and

Minimum

Part Name

Thickness

Spray Tip (shoulder)

.199"

Check Valve Cage

.163" -.165"

Check Valve

.022"

Valve Spring Cage

.602"

TABLE 1. Minimum Thickness (Used Parts)

1. Clean the lapping blocks (J 22090) with compressed

air. Do not use a cloth or any other material for this

purpose.

2. Spread a good quality 600 grit dry lapping powder on

one of the lapping blocks.

3. Place the part to be lapped flat on the block as

shown in Fig. 33 and, using a figure eight motion, move

it back and forth across the block. Do not press on the

part, but use just enough pressure to keep the part flat

on the block. It is important that the part be kept flat on

Fig. 40. Tightening Injector Nut by Hand

the block at all times.

4. After each four or five passes, clean the lapping

powder from the part by drawing it across a clean piece

of tissue placed on a flat surface and inspect the part.

Do not lap excessively (refer to Table 1).

10-3-20