TM 5-3895-359-14&P

or scratches. Also check the surface which contacts the

injector bushing for scratches, scuff marks or other

damage. If necessary, lap this surface. A faulty sealing

surface at this point will result in high fuel consumption

and contamination of the lubricating oil. Replace any

loose injector body plugs or a loose dowel pin. Install

the proper number tag on a service replacement injector

body.

Inspect the injector plunger and bushing for scoring,

erosion, chipping or wear. Check for sharp edges on

that portion of the plunger which rides in the gear.

Remove any sharp edges with a 500 grit stone. Wash

the plunger after stoning it. Check the port holes in the

inner diameter of the bushing for cracks or chipping.

Slip the plunger into the bushing and check for free

movement. Replace the plunger and bushing as an

assembly if any of the above damage is noted, since

they are mated parts. Use new mated factory parts to

assure the best performance from the injector.

Injector plungers cannot be reworked to change the

output. Grinding will destroy the hardened case at the

helix and result in chipping and seizure or scoring of the

plunger.

Examine the spray tip seating surface of the injector nut

and spray tip for nicks, burrs, erosion or brinelling.

Reseat the surface or replace the nut or tip if it is

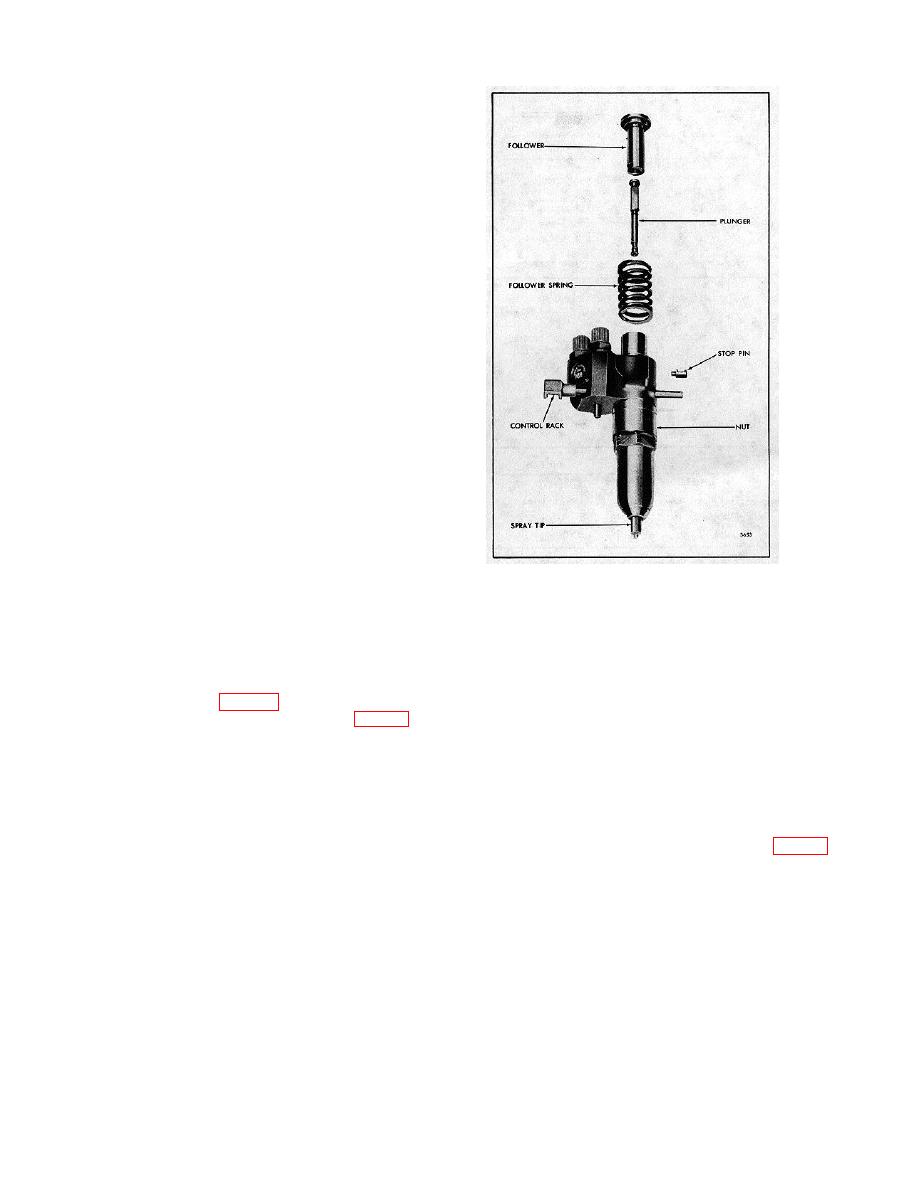

Fig. 37. Injector Plunger, Follower and Relative

severely damaged.

Location of Parts

The injector valve spring plays an important part in

stick 6 to 12 times, applying a light pressure with the

establishing the valve opening pressure of the injector

thumb and forefinger.

assembly. Replace a worn or broken spring.

NOTE:

Inspect the sealing surfaces of the injector parts

Be sure that no compound is

indicated by arrows in Fig. 31. Examine the sealing

accidentally placed on the lapped

surfaces with a magnifying glass as shown in Fig. 32 for

surfaces located higher up in the

even the slightest imperfections will prevent the injector

spray tip.

The slightest lapping

from operating properly. Check for burrs, nicks, erosion,

action on these surfaces can alter

cracks, chipping and excessive wear. Also check for

the near-perfect fit between the

enlarged orifices in the spray tip. Replace damaged or

needle valve and tip.

excessively worn parts. Check the minimum thickness

of the lapped parts as noted in Table 1.

Before reinstalling used injector parts, lap all of the

sealing surfaces indicated by the arrows in Fig. 31. It is

Examine the seating area of the needle valve for wear

also good practice to lightly lap the sealing surfaces of

or damage. Also examine the needle quill and its

new injector parts which may become burred or nicked

contact point with the valve spring seat. Replace

during handling.

damaged or excessively worn parts.

NOTE:

Examine the needle valve seat area in the spray tip for

The sealing surface of current spray

foreign material. The smallest particle of such material

tips is precision lapped by a new

can prevent the needle valve from seating properly.

process which leaves the surface

Polish the seat area with polishing stick J 22964. Coat

with a dull satin-like finish; the

only the tapered end of the stick with polishing

lapped surface on former spray tips

compound J 23038 and insert it directly into the center

was

of the spray tip until it bottoms. Rotate the

10-3-19