TM 5-3895-359-14&P

7. Shut the calibrator off (the calibrator will stop in less

time at full-fuel).

8. Observe the vial reading and refer to Fig. 19 to

determine whether the injector fuel output falls within the

specified limits. If the quantity of fuel in the vial does

not fall within the specified limits, refer to Trouble

the cause and remedy.

NOTE:

Refer to Page 10-3-59 for different

factors that may affect the injector

calibrator output reading.

The calibrator may be used to check and select a set of

injectors which will inject the same amount of fuel in

each cylinder at a given throttle setting, thus resulting in

a smooth running, well balanced engine.

An injector which passes all of the above tests may be

put back into service. However, an injector which fails

to pass one or more of the tests must be rebuilt and

checked on the calibrator.

Any injector which is disassembled and rebuilt must be

Fig. 26. Removing Spray Tip from Injector Nut

tested again before being placed in service.

sound briefly until the lubricating oil

reaches the proper pressure.

Disassemble Injector

5. After the calibrator has started, set the injector rack

If required, disassemble an injector as follows:

into the full-fuel position. Allow the injector to operate

for approximately 30 seconds to purge the air that may

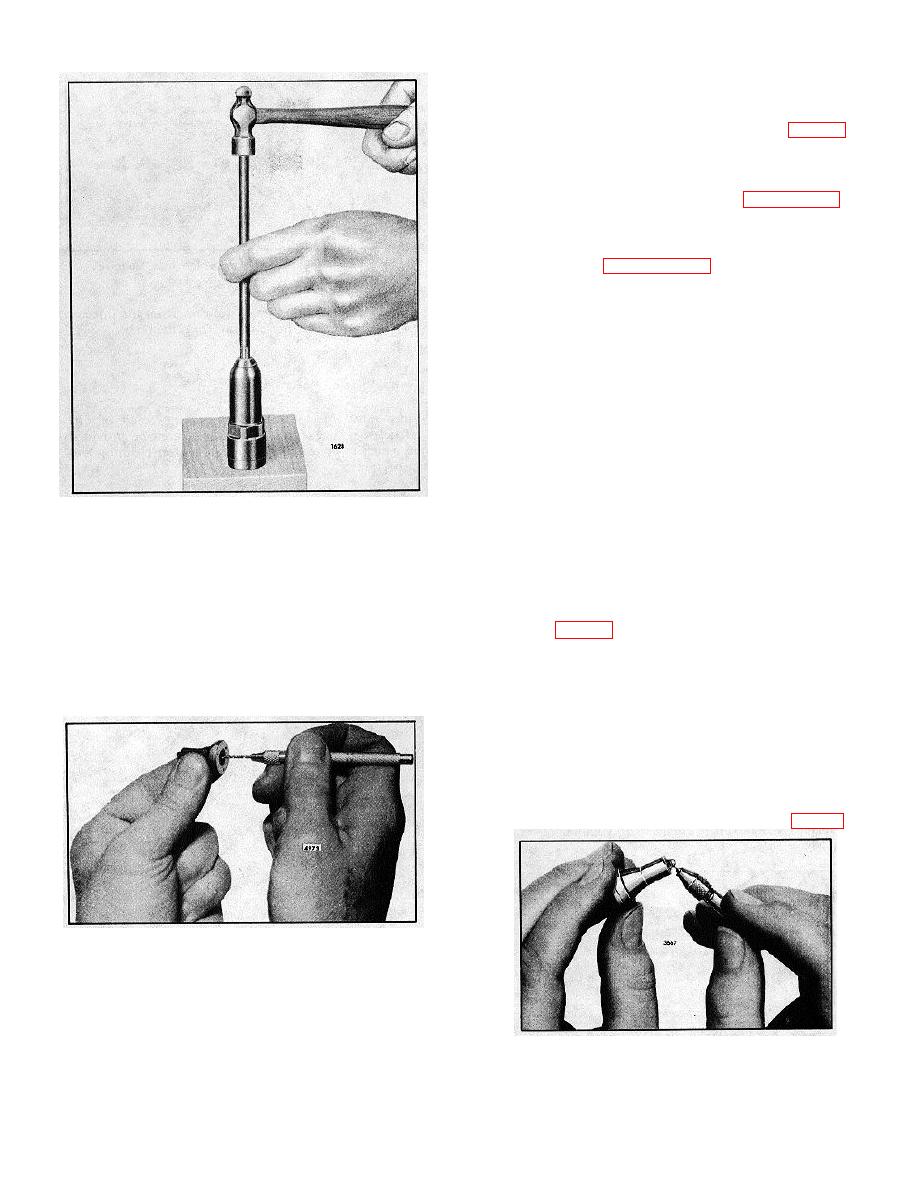

1. Support the injector upright in injector holding fixture

be in the system.

J 22396 (Fig. 23) and remove the filter caps, gaskets

and filters.

6. After the air is purged, press the fuel flow start button

(red). This will start the flow of fuel into the vial. The

NOTE:

fuel flow to the vial will automatically stop after 1000

Whenever

a

fuel

injector

is

strokes.

disassembled, discard the filters and

gaskets and replace with new filters

and gaskets. In the offset injector, a

filter is used in the inlet side only.

No filter is required in the outlet side

(Fig. .34).

2. Compress the follower spring as shown in Fig. 11.

Fig. 27. Cleaning injector Spray Tip

Fig. 28. Cleaning Spray Tip Orifices

10-3-15