TM 5-3895-359-14&P

NOTE:

Care must be exercised when

inserting the carbon remover J 9464-

01 in the spray tip to avoid

contacting the needle valve seat in

the tip.

Wash the tip in fuel oil and dry it with compressed air.

Clean the spray tip orifices with pin vise J 4298-1 and

the proper size spray tip cleaning wire. Use wire J

21460 to clean .0055 " diameter holes and wire J 21461

to clean .006 " diameter holes (Fig. 28).

Before using the wire, hone the end until it is smooth

and free of burrs and taper the end a distance of 1/16 "

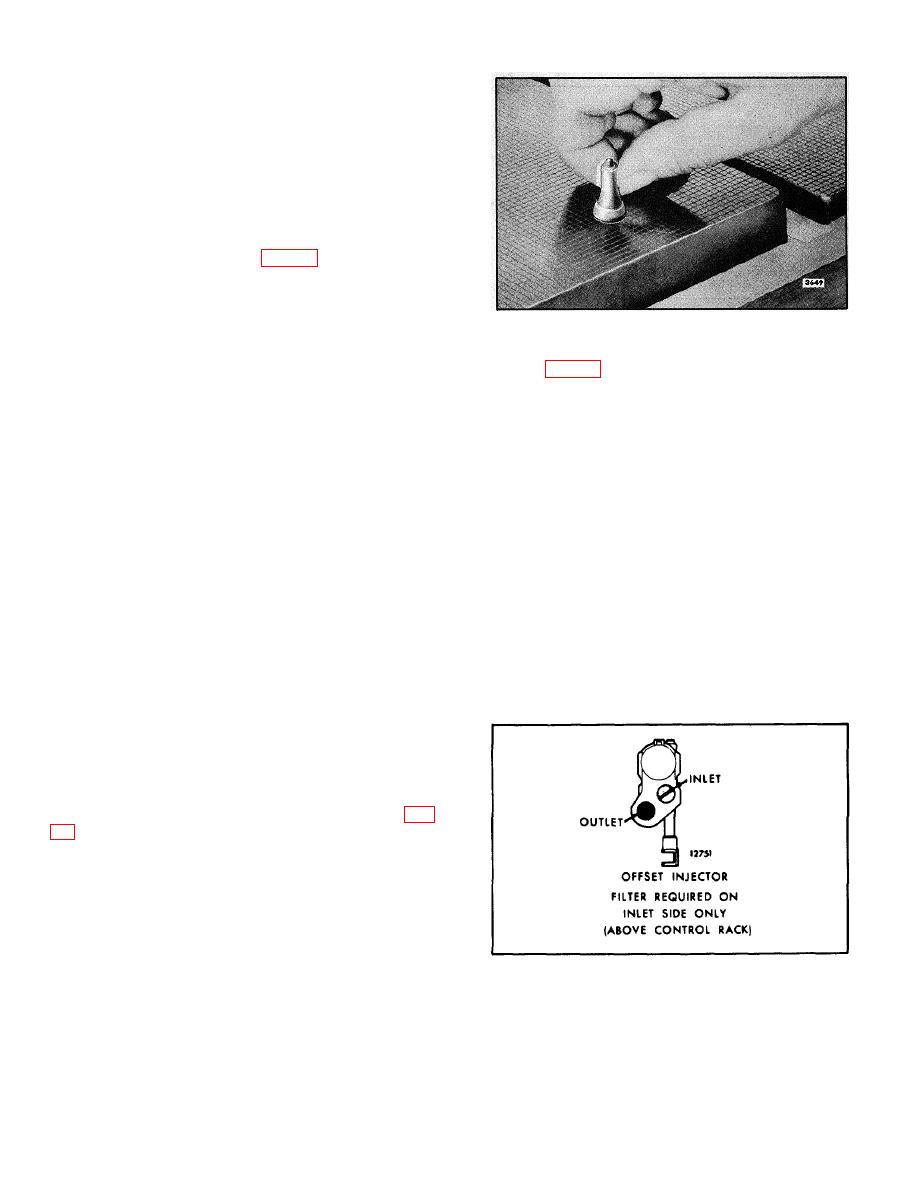

Fig. 33. Lapping Spray Tip on Lapping Blocks J

with stone J 8170. Allow the wire to extend 1/8 " from

22090

tool J 4298-1.

J 9418-5 (Fig. 30). Use care to minimize removing metal

The exterior surface of an injector spray tip may be

or setting up burrs on the spray tip seat. Remove only

cleaned by using a brass wire buffing wheel, tool J 7944.

enough metal to produce a clean uniform seat to prevent

To obtain a good polishing effect and longer brush life,

leakage between the tip and the nut. Carefully insert

the buffing wheel should be installed on a motor that

carbon remover J 9418-1 in the injector nut. Turn it

turns the wheel at approximately 3000 rpm.

A

clockwise to remove the carbon deposits on the flat spray

convenient method of holding the spray tip while

tip seat.

cleaning and polishing is to place the tip over the drill

end of the spray tip cleaner tool J 1243 and hold the

Wash the injector nut in clean fuel oil and dry it with

body of the tip against the buffing wheel. In this way,

compressed air. Carbon deposits on the spray tip seating

the spray tip is rotated while being buffed.

surfaces of the injector nut will result in poor sealing and

CAUTION:

consequent fuel leakage around the spray tip.

Do not buff excessively. Do not use

a steel wire buffing wheel or the

When handling the injector plunger, do not touch the

spray tip holes may be distorted.

finished plunger surfaces with your fingers. Wash the

When the body of the spray tip is clean, lightly buff the

plunger and bushing with clean fuel oil and dry them with

tip end in the same manner. This cleans the spray tip

compressed air. Be sure the high pressure bleed hole in

orifice area and will not plug the orifices.

the side of the bushing is not plugged. If this hole is

plugged, fuel leakage will occur at the upper end of the

Wash the spray tip in clean fuel oil and dry it with

bushing where it will drain out of the injector body vent

compressed air.

and rack holes, during engine

Clean and brush all of the passages in the injector body,

using fuel hole cleaning brush J 8152 and rack hole

cleaning brush J 8150. Blow out the passages and dry

them with compressed air.

Carefully insert reamer J 21089 in the injector body (Fig.

remove the reamer and check the face of the ring for

reamer contact over the entire face of the ring. If

necessary, repeat the reaming procedure until the

reamer does make contact with the entire face of the

ring. Clean up the opposite side of the ring in the same

manner.

Carefully insert a .375" diameter straight fluted reamer

Fig. 34. Location of Filter in Injector Body

inside the ring bore in the injector body. Turn the

reamer in a clockwise direction and remove any burrs

inside the ring bore. Then wash the injector body in

clean fuel oil and dry it with compressed air.

Remove the carbon deposits from the lower inside

diameter taper of the injector nut with carbon remover

10-3-17