TM 5-3895-359-14&P

it is less than .018", inspect for foreign material between

the needle valve and the tip seat.

Meat

4. If the needle valve lift is within limits, install a new

needle valve spring and recheck the valve opening

pressure and valve action. Low valve opening pressure or

poor atomization with a new spring and seat indicates the

spray tip and needle valve assembly should be replaced.

5. Reassemble the injector as outlined under Assemble

Injector and check the injector output with calibrator J

22410.

Needle Valve Tip Test (Using Auxiliary Tester J 22640)

1. Connect the pipe from auxiliary tester J 22640 to the

rear of the J 23010 tester at the connection located near

the bottom of the tester (Fig. 17).

2. Assemble cleaned injector parts, including the check

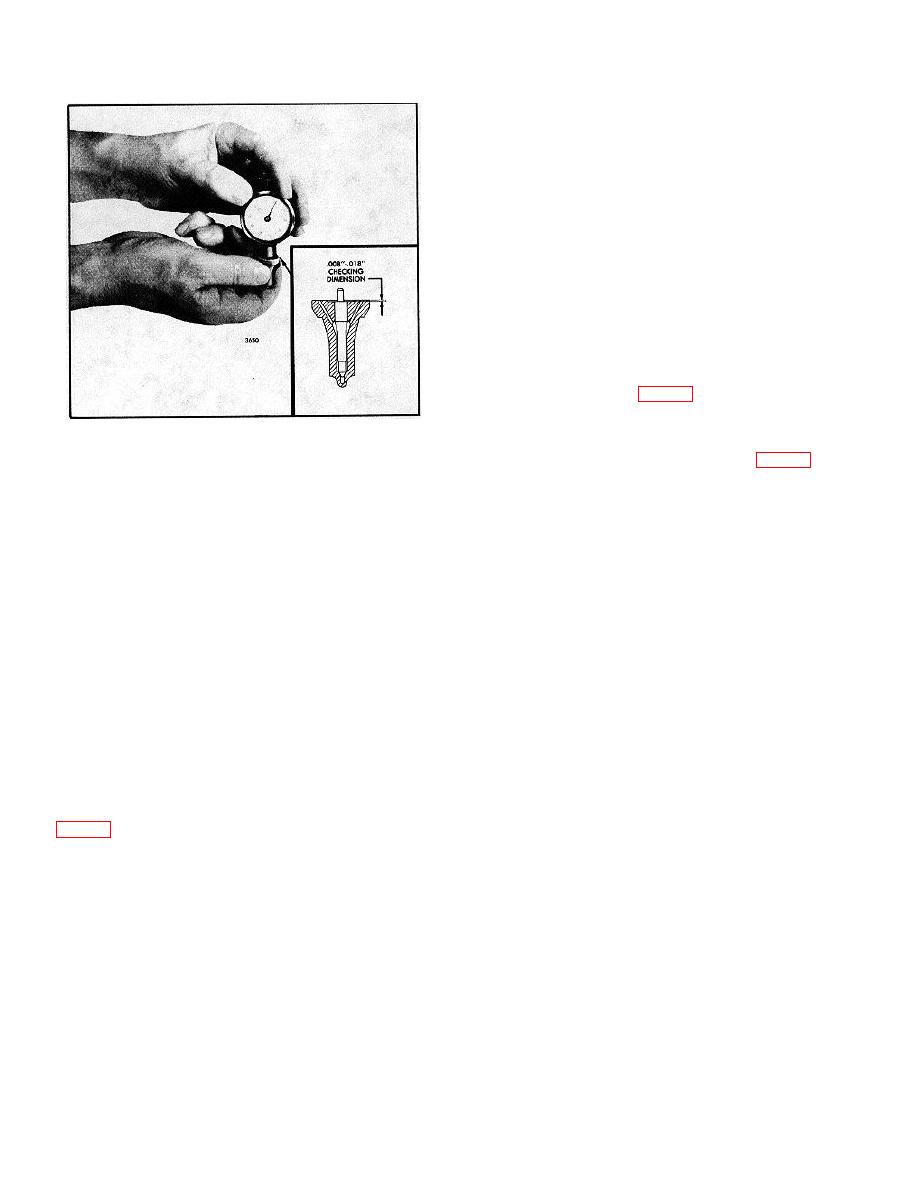

Fig. 16. Checking Needle Valve Lift

valve cage, spring, spring seat, spring cage and spray tip

3300 psi (15 158 and 22 737 kPa). The opening and

assembly, on the auxiliary tester J 22640 (Fig. 18).

closing action should be sharp and produce a normal,

3. Carefully pilot the injector nut over the spray tip and

finely atomized spray pattern.

valve parts and thread it on the auxiliary tester.

If the valve opening pressure is below 2200 psi (15 158

4. Tighten the injector nut.

kPa) and/or atomization is poor, the cause is usually a

weak valve spring or a poor needle valve seat.

5. Open the valve on the auxiliary tester and place lever

4 in the up (horizontal) position.

If the valve opening pressure is within 2200-3300 psi (15

158-22 737 kPa), proceed to check for spray tip leakage

6. Install the shield on the auxiliary tester and operate

as follows:

pump lever 1 until the needle valve has opened several

times to purge the air from the system.

a. Actuate pump lever 1 several times and hold

the pressure at 1500 psi (10 335 kPa) for 15

7. Operate pump lever 1 rapidly with smooth even strokes

seconds.

(40 strokes per minute) simulating the action of the tip

b. Inspect the spray tip for leakage. There should

functioning in the engine. Note the pressure at which the

be no fuel droplets, although a slight wetting at

test oil delivery occurs. Test oil delivery should occur

the spray tip is permissable.

between 2200 and 3300 psi (15 158 and 22 737 kPa).

The beginning and ending of delivery should be sharp and

Needle Valve Lift Test

the test oil should be a finely atomized spray.

To measure the needle valve lift, use tool J 9462-02

If the valve opening pressure is below 2200 psi (15 158

(Fig. 16) as follows:

kPa) and/or atomization is poor, the cause is usually a

weak valve spring or poor needle valve seat.

1. Zero the indicator by placing the bottom surface of

the plunger assembly on a flat surface and zero the

If the valve opening pressure is within 2200-3300 psi (15

indicator dial.

158-22 737 kPa), proceed to check for spray tip leakage

as follows:

2. Place the spray tip and needle valve assembly tight

against the bottom of the gage with the quill of the

a. Actuate the pump lever several times and hold the

needle valve in the hole in the plunger.

pressure at 1500 psi (10 335 kPa) for 15 seconds.

3. While holding the spray tip and needle valve

assembly tight against the gage, read the needle valve

b. Inspect the spray tip for leakage. There should be

lift on the indicator. The lift should be .008 " to .018 ". If

it exceeds .018 ", the tip assembly must be replaced. If

10-3-11