TM 5-3895-359-14&P

4. Remove the two rocker shaft bracket bolts and swing

An injector that passes all of the tests outlined below

the rocker arms away from the injector and valves (Fig.

may be considered to be satisfactory for service without

disassembly. except for the visual check of the plunger.

5. Remove the injector clamp bolt, special washer and

However, an injector that fails to pass one or more of

clamp.

the tests is unsatisfactory. Perform all of the tests

before disassembling an injector to correct any one

6. Loosen the inner and outer adjusting screws on the

condition.

injector rack control lever and slide the lever away from

the injector.

Identify each injector and record the pressure drop and

7. Lift the injector from its seat in the cylinder head.

fuel output as indicated by the following tests:

8. Cover the injector hole in the cylinder head to keep

Injector Control Rack and Plunger Movement Test

foreign material out.

9. Clean the exterior of the injector with clean fuel oil

Place the injector in the injector fixture and rack

and dry it with compressed air.

freeness tester J 22396. Refer to Fig. 8 and place the

handle on top of the injector follower.

TEST INJECTOR

If necessary, adjust the contact screw in the handle to

WARNING

ensure the contact screw is at the center of the follower

The fuel spray from an injector can

when the follower spring is compressed.

penetrate the skin. Fuel oil which

enters the blood stream can cause a

With the injector control rack held in the no-fuel position,

serious infection. Therefore, follow

push the handle down and depress the follower to the

instructions and use the proper

bottom of its stroke. Then very slowly release the

equipment to test an injector.

pressure on the handle while moving the control rack up

and down as shown in Fig. 8 until the

If inspection does not reveal any external damage, then

perform a series of tests to determine the condition of

the injector to avoid unnecessary overhauling. Tests

must be performed using injector test oil J 26400.

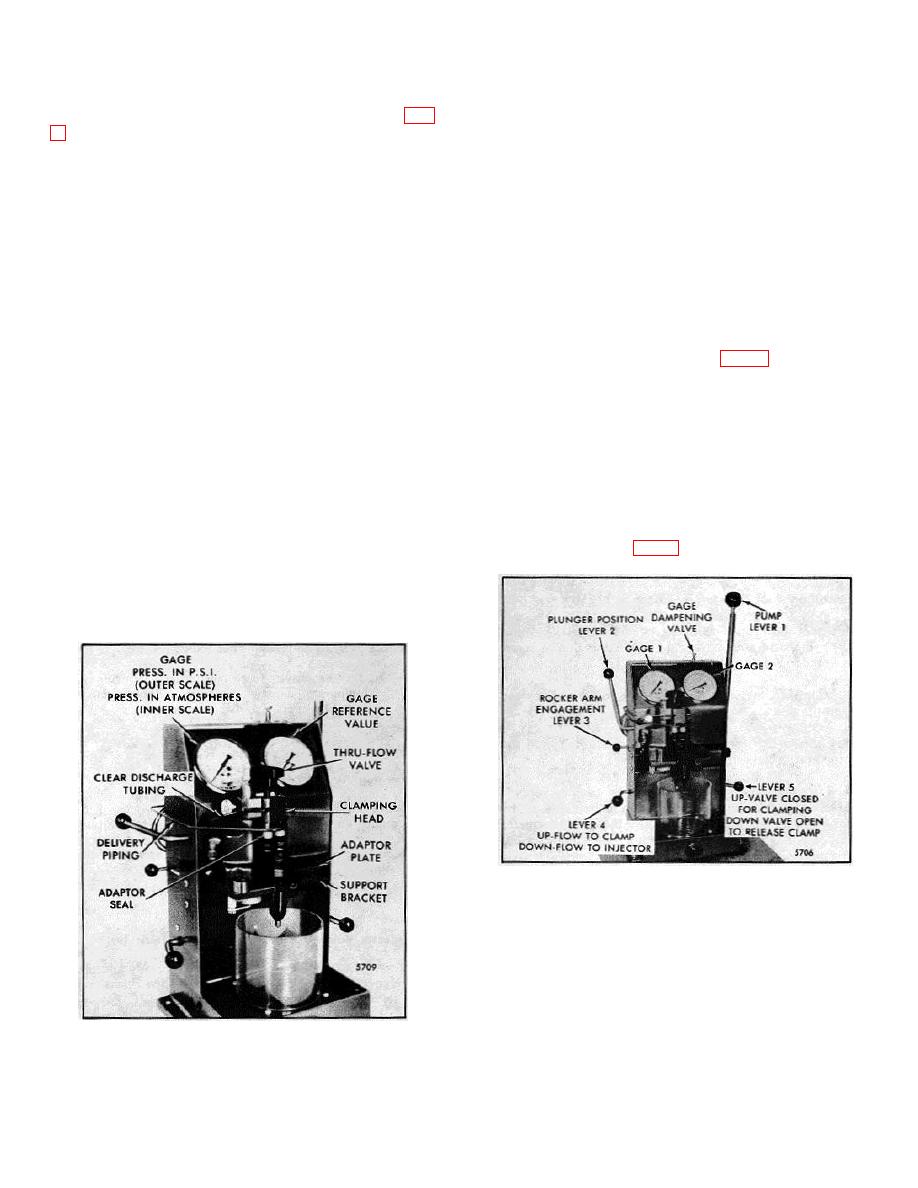

Fig. 13. Injector in Position for Testing with Tester

J 23010

Fig. 12. Injector Installed in Tester J 23010 with

clamping Head

10-3-7