TM 5-3895-359-14&P

The highest pressure reference number shown on gage

2 will be reached just before injection ends. Use the

following reference values to determine the relative

acceptability of the injector. Reference values for

Series 71 injectors, are from 127 minimum to 146

maximum.

NOTE:

The reference value obtained when

pop testing the needle valve

injectors is to be used as a trouble

shooting and diagnosis aid. This

allows

comparative

testing

of

injectors without disassembly. Exact

valve opening pressure values can

only be determined by the Needle

Valve Tip Test using tester J 23010

and tip test adaptor J 23010-129 or

auxiliary tester J 22640.

Injector High Pressure Test

This test checks for leaks at the filter cap gaskets, body

plugs and nut seal ring.

1. Clamp the injector properly and purge the air from

the system.

2. Close the Thru Flow valve. but do not overtighten.

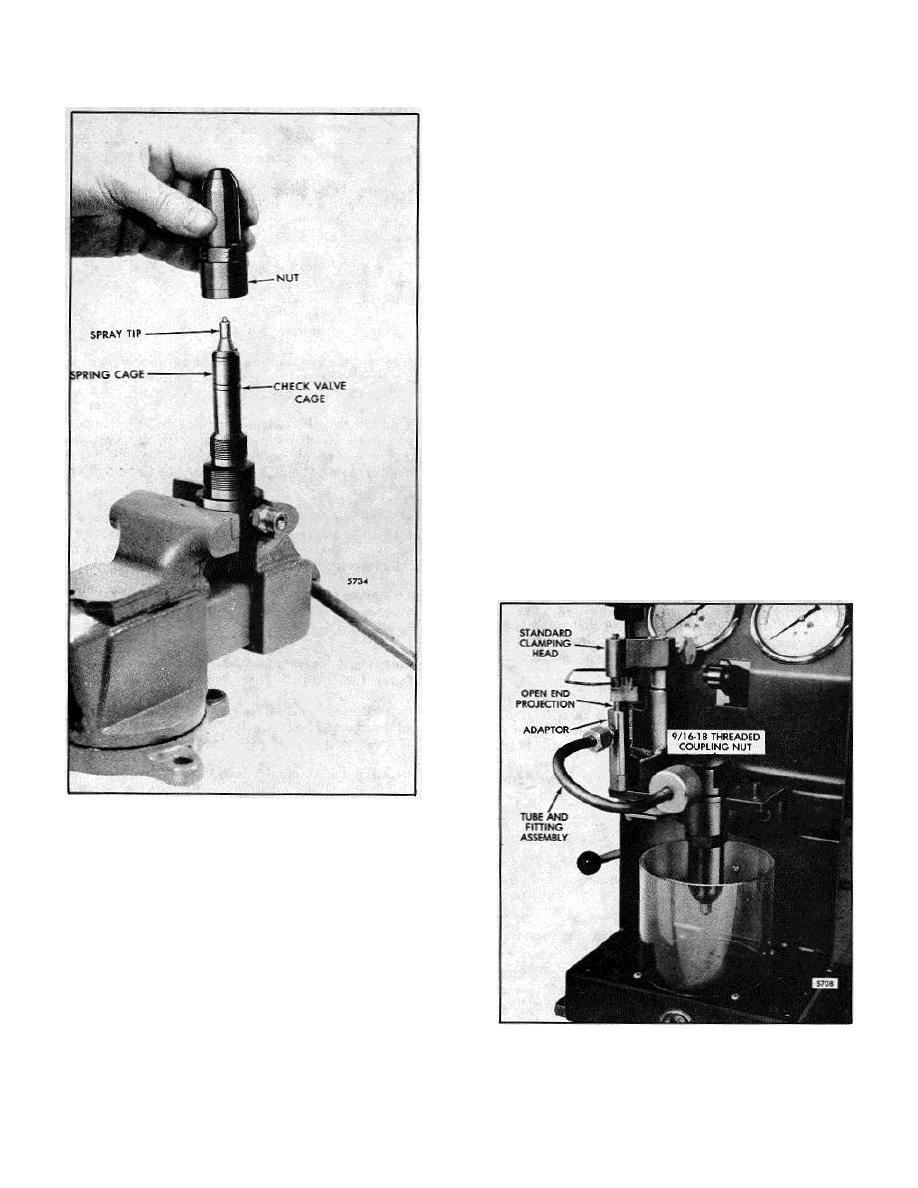

Fig. 14 Assembling Injector Valve Parts on Tip

Tester Adaptor J 23010-129

3. Position the injector rack in the full-fuel position.

4. Place pump lever I in the vertical position.

5. Move lever 3 to the forward detent position.

6. The injector follower should be depressed rapidly (40

to 80 strokes per minute) to simulate operation in the

engine. Observe the spray pattern to see that all spray

orifices are open and dispersing the test oil evenly. The

Fig. 15. Adaptor and Tube Assembly on Injector

beginning and ending of injection should be sharp and

the test oil should be finely atomized with no drops of

Tester J 23010

test oil forming on the end of the tip.

10-3-9