TM 5-3895-359-14&P

remaining plug as outlined in steps "a" through " "

g.

Inspection

Soak the camshaft in clean fuel oil. Then, run a wire

brush through the oil gallery to remove any foreign

material or sludge. Clean the exterior of the camshaft

and blow out the gallery and the oil holes with

compressed air. Clean the gears, camshaft hearings

and related parts with fuel oil and dry them with

compressed air.

Inspect the cams and journals for wear or scoring. If the

cams are scored, inspect the cam followers as outlined

on Page 10-2-31. Also, inspect the camshaft keyways

and threads for damage.

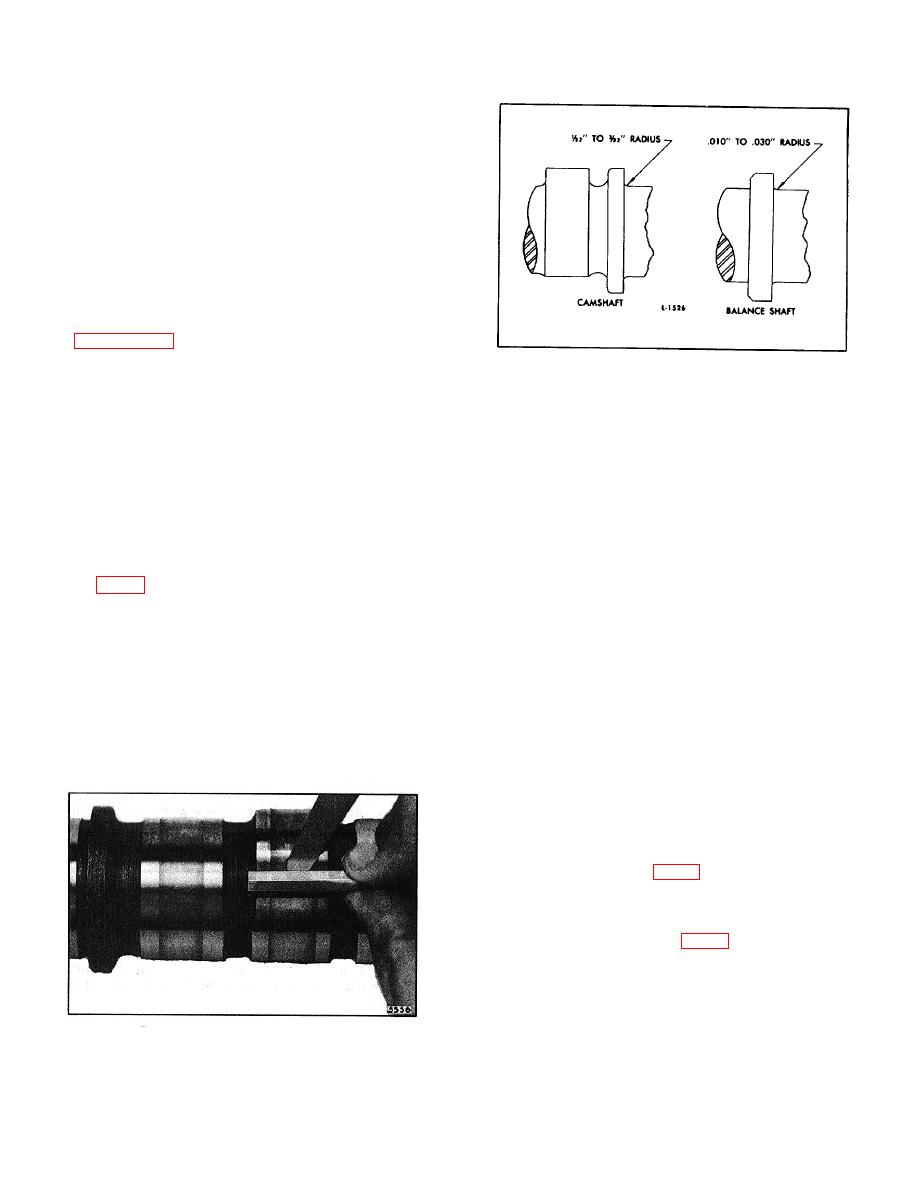

Fig. 9. Camshaft and Balance Shaft Journal Fillets

If there is a doubt as to the acceptability of the camshaft

Examine both faces of each camshaft rear end bearing

for further service determine the extent of cam lobe

and thrust washer. Also, examine the surfaces of each

wear as follows:

camshaft and camshaft gear which contact the thrust

washers. Replace excessively worn or scored parts.

NOTE:

Camshaft or camshaft gear thrust surfaces that are not

The camshaft can be in or out of the

scratched too severely may be smoothed down with an

engine during this inspection.

oil stone.

1. With a tapered leaf set of feeler gages (.0015 " .0100

NOTE:

") and a piece of square hard material 1/8" X 3/8 " X 1 "

If a new camshaft is to be installed,

measure the flat on the injector rise side of the cam

steam clean it to remove the rust

lobes (Fig. 8).

preventive and blow out the oil

passages with compressed air.

2. If the flats measure less than .003 " in depth and

there are no other defects the camshaft is satisfactory

New standard size-thrust washers are .120 " to .122"

for service.

thick. The clearance between the thrust washer and the

thrust shoulder of the camshaft is .004 " to .012 " with

3. A slightly worn lobe still within acceptable limits may

new parts, or a maximum of .018" with used parts.

be stoned and smoothed over with a fine crocus cloth.

Excessive clearance may be reduced by using thrust

washers which are .005 " or .010 " oversize.

Check the runout at the center bearing with the

camshaft mounted on the end bearing surfaces. Runout

When the thrust surfaces of a camshaft or balance shaft

should not exceed .002 ".

are ground undersize, special care must be taken as

follows:

1. Leave a .031 " to .094 " radius between the bearing

surface of the thrust collar shoulder and the bearing

surface of the camshaft (Fig. 9).

2. Leave a .010 " to .030 " radius between the bearing

surface of the thrust collar shoulder and the bearing

surface of the balance shaft (Fig. 9).

Use a fillet radius gage to measure the specified radii.

Fig. 8. Checking Cam Lobe Wear

10-2-110