TM 5-3895-359-14&P

FLYWHEEL

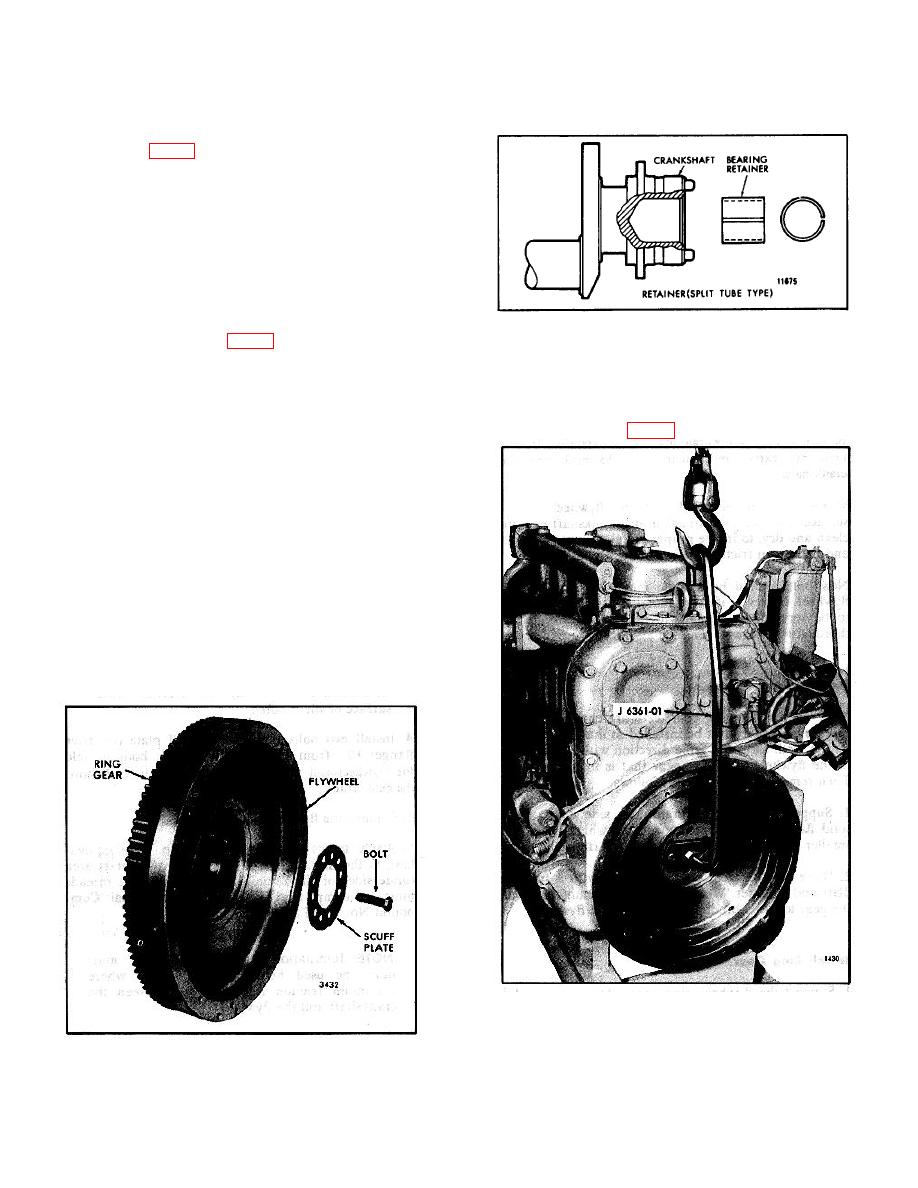

The flywheel (Fig. 1) is attached to the rear end of the

crankshaft with six self-locking bolts. Two dowels in the

end of the crankshaft aid flywheel alignment and

provide support when the flywheel bolts are removed.

scuff plate is used between the flywheel and the bolt

heads to prevent the bolt heads from scoring the

flywheel surface.

A steel ring gear, which meshes with the starting motor

pinion, is shrunk onto the rim of the flywheel.

Fig. 2. Pilot Bearing Retainer

A split tube type retainer (Fig. 2) is driven in the end of

the crankshaft to prevent the pilot bearing from entering

2. Attach flywheel lifting tool J 6361-01 to the flywheel

the crankshaft cavity.

with two 7/16" -14 bolts of suitable length or use tool J

25026. Remove the remaining flywheel attaching bolt.

The flywheel is machined to provide true alignment with

3. Attach a chain hoist to the lifting tool to support the

the clutch, and the center bore provides for installation

flywheel as shown in Fig. 3.

of a clutch pilot bearing. The clutch is bolted to the

flywheel.

The flywheel must be removed for service operations

such as replacing the starter ring gear, crankshaft or

flywheel housing.

Remove Flywheel (Transmission Removed)

1. Remove the six flywheel attaching bolts and scuff

plate.

CAUTION Install one flywheel bolt after removing the

scuff plate to hold the flywheel in place until the lifting

tool is attached.

Fig. 3. Removing Flywheel

Fig. 1. Typical Flywheel Assembly

10-2-71