TM 5-3895-359-14&P

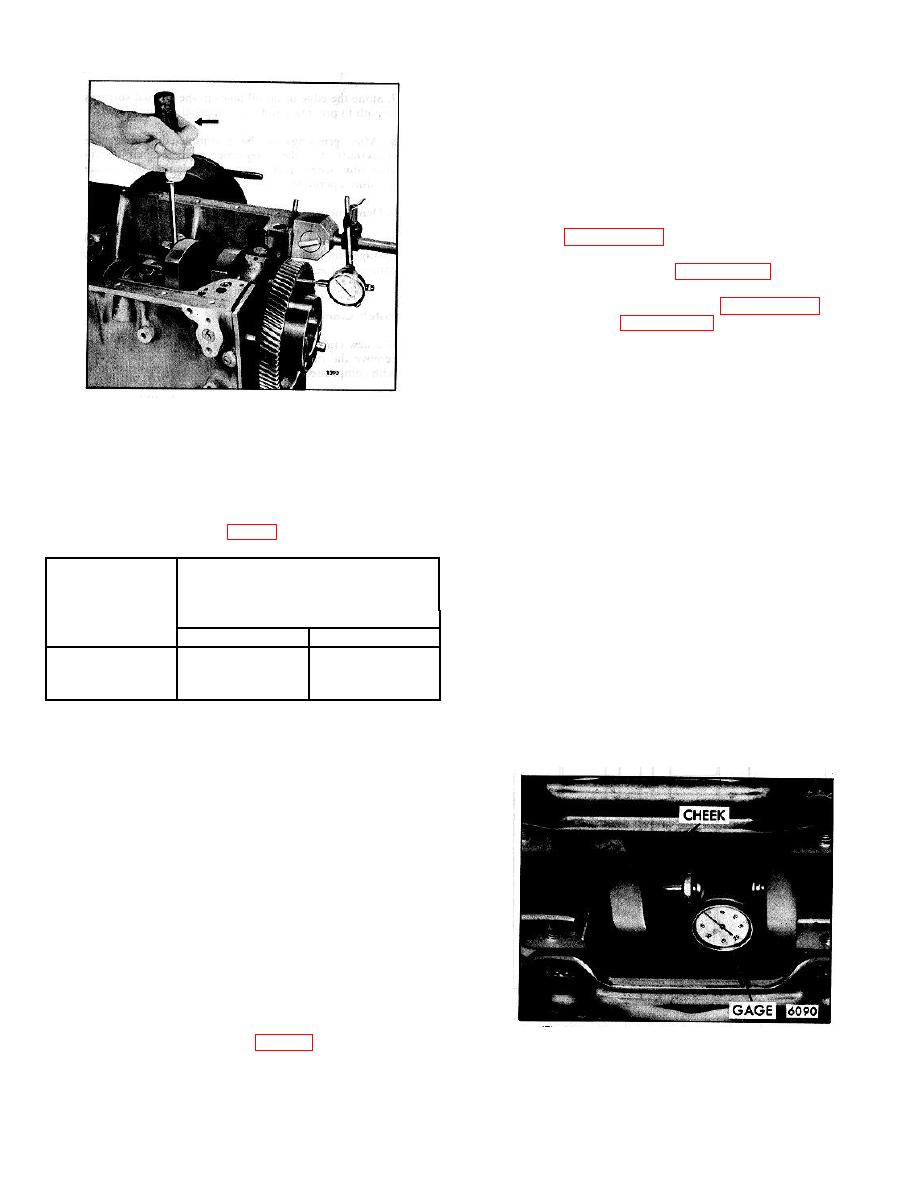

the other side of the bearing cap. Force the crankshaft

in the opposite direction and note the amount of end

play on the dial. The end play should be .004 " to .011 "

with new parts or a maximum of .018 " with used parts.

Insufficient end play can be the result of a misaligned

rear main bearing or a burr or dirt on the inner face of

one or more of the thrust washers.

8. Install the cylinder liner, piston and connecting rod

assemblies (Page 10-2-99).

9. Install the cylinder head (Page 10-2-25).

10. Install the flywheel housing (Page 10-2-76), then

install the flywheel (Page 10-2-72).

11. Install the crankshaft front cover and gasket.

Fig. 10. Checking Crankshaft End Play

CAUTION:

Install the oil seal spacer or inner

NOTE:

cone after the crankshaft front cover

If the crankshaft thrust surfaces were

is in place to avoid damage to the oil

reground, it may be necessary to

seal lip.

install oversize thrust washers on

one or both sides of the rear main

12. Install the engine front support.

journal. Refer to Fig. 9 and Table 3.

13. Install the vibration damper inner cone or oil seal

Thrust Washer

spacer.

Nominol

Thickness

14. Install the vibration damper assembly.

Size

15. Install the crankshaft pulley.

Min.

Max.

Standard

.1190"

.1220"

16. Install the lubricating oil pump assembly (Page 10-

.005" Oversize

.1240"

.1270"

5-10).

.010" Oversize

.1290"

.1320"

TABLE 3

17. Check the crankshaft for distortion at the rear

connecting rod journal counterweights before and after

5. Install the lower bearing shells (no oil grooves) in the

installing the transmission. An improperly installed

bearing caps. It' the old bearing shells are to be used

again, install them in the same bearing caps from which

they were removed.

6. Install the bearing caps and lower bearing shells as

outlined under install Main Bearing Shells on Page 10-2-

62.

NOTE:

If the hearings have been installed

properly, the crankshaft will turn

freely with all of the main bearing

cap bolts drawn to the specified

7. Check the crankshaft end play by moving the

Fig. 11. Crankshaft Distortion Measuring Gage

crankshaft toward the gage (Fig. 10) with a pry bar.

Mounted on Crankshaft.

Keep a constant pressure on the pry bar and set the dial

indicator to zero. Then remove and insert the pry bar on

10-2-54