TM 5-3895-359-14&P

CRANKSHAFT MAIN BEARINGS

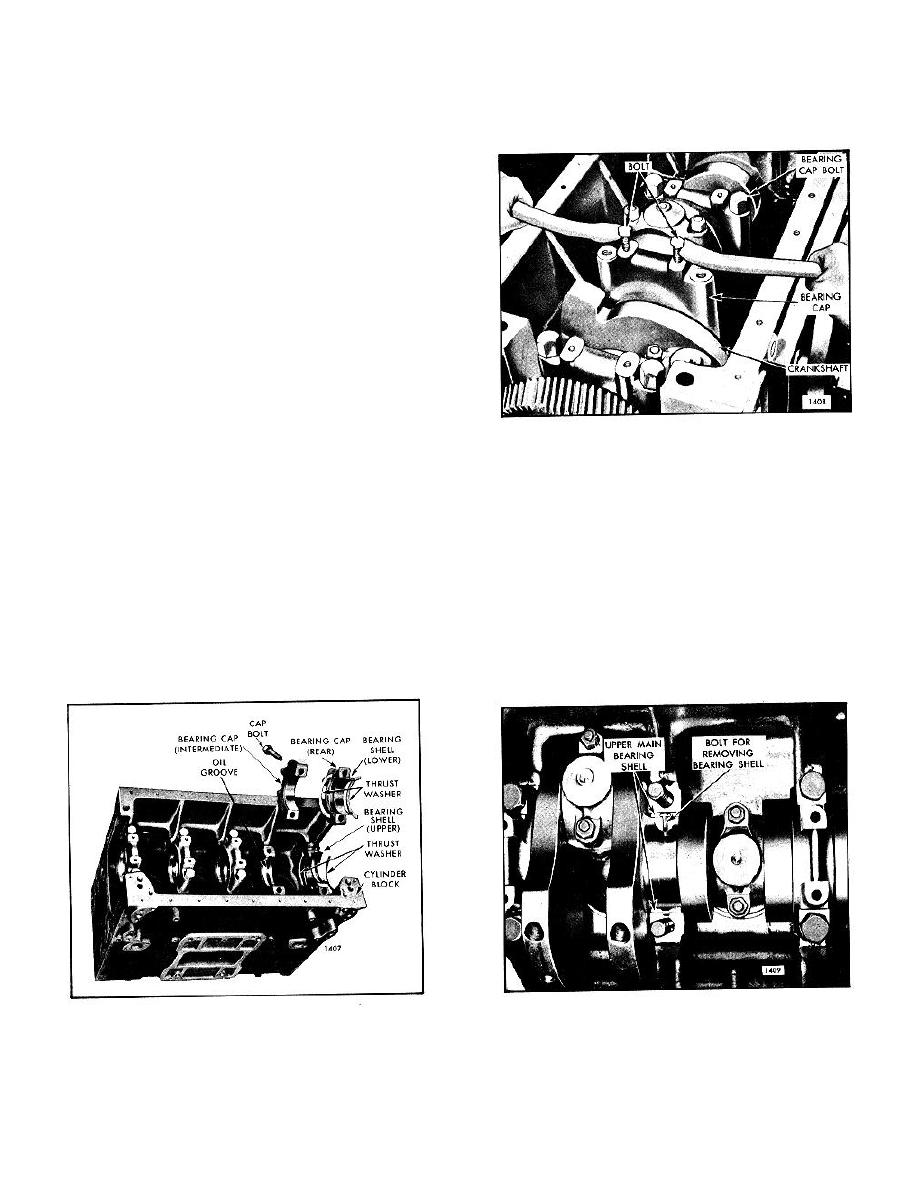

The crankshaft main bearing shells (Fig. I) are precision

made and are replaceable without machining. They

consist of an upper bearing shell seated in each cylinder

block main bearing support and a lower bearing shell

seated in each main bearing cap. The bearing shells

are prevented from endwise or radial movement by a

tang at the parting line at one end of each bearing shell.

The tangs on the lower bearing shells are off-center and

the tangs on the upper bearing shells are centered to aid

correct installation.

Various types of bearings have been used. Currently,

multiple layer copper-lead coplated or aluminum

triplated bearings are in use. These bearings have an

inner surface, called the matrix, of copper-lead or

aluminum. A thin deposit of babbitt is then plated onto

the matrix. This babbitt overlay has excellent resistance

Fig. 2. Removing Main Bearing Cap

to friction, corrosion and scoring tendencies which,

The lower main bearing shells have no oil grooves,

combined with the material of the matrix, provides

therefore, the upper and lower bearing shells must not

improved load carrying characteristics. These bearings

be interchanged.

are identified by the satin silver sheen of the babbitt

when new and a dull gray after being in service. The

Thrust washers (Fig. I), on each side of the rear main

former copper-lead bearings had a copper color when

bearing, absorb the crankshaft thrust. The lower halves

new and turned very dark during engine operation.

of the two-piece washers are doweled to the bearing

cap; the upper halves are not doweled.

An oil hole in the groove of each upper bearing shell,

midway between the parting lines, registers with a

Main bearing trouble is ordinarily indicated by low or no

vertical oil passage in the cylinder block. Lubricating oil,

oil pressure. All of the main bearing load is carried on

under pressure, passes from the cylinder block oil

the lower bearings; therefore, wear will occur on the

gallery by way of the bearing shells to the drilled

lower bearing shells first. The condition of the lower

passages in the crankshaft, then to the connecting rods

bearing shells may be observed by removing the main

and connecting rod bearings.

bearing caps.

Fig. 3. Removing Upper Main Bearing Shell (Except

Fig. 1. Main Bearing Shells, Bearing Caps and

Rear Main)

Crankshaft Thrust Washers

10-2-59