TM 5-3895-359-14&P

Fig. 7 - Cleaning Cylinder Block

25. Turn the holding lugs crosswise in the air box

openings and tighten the lock nuts, drawing the engine

tight against the adaptor plate.

26. To be sure the engine does not shift on or break

away from the overhaul stand, insert a 7/16"-14 x 2"

bolt, with a plain washer under the head of the bolt,

through the hole in the adaptor plate and into the pad on

the cylinder block.

WARNING

Be sure the engine is securely mounted to the

overhaul stand before releasing the lifting sling.

Severe injury to personnel and destruction of

engine parts will result if the engine breaks

away from the overhaul stand.

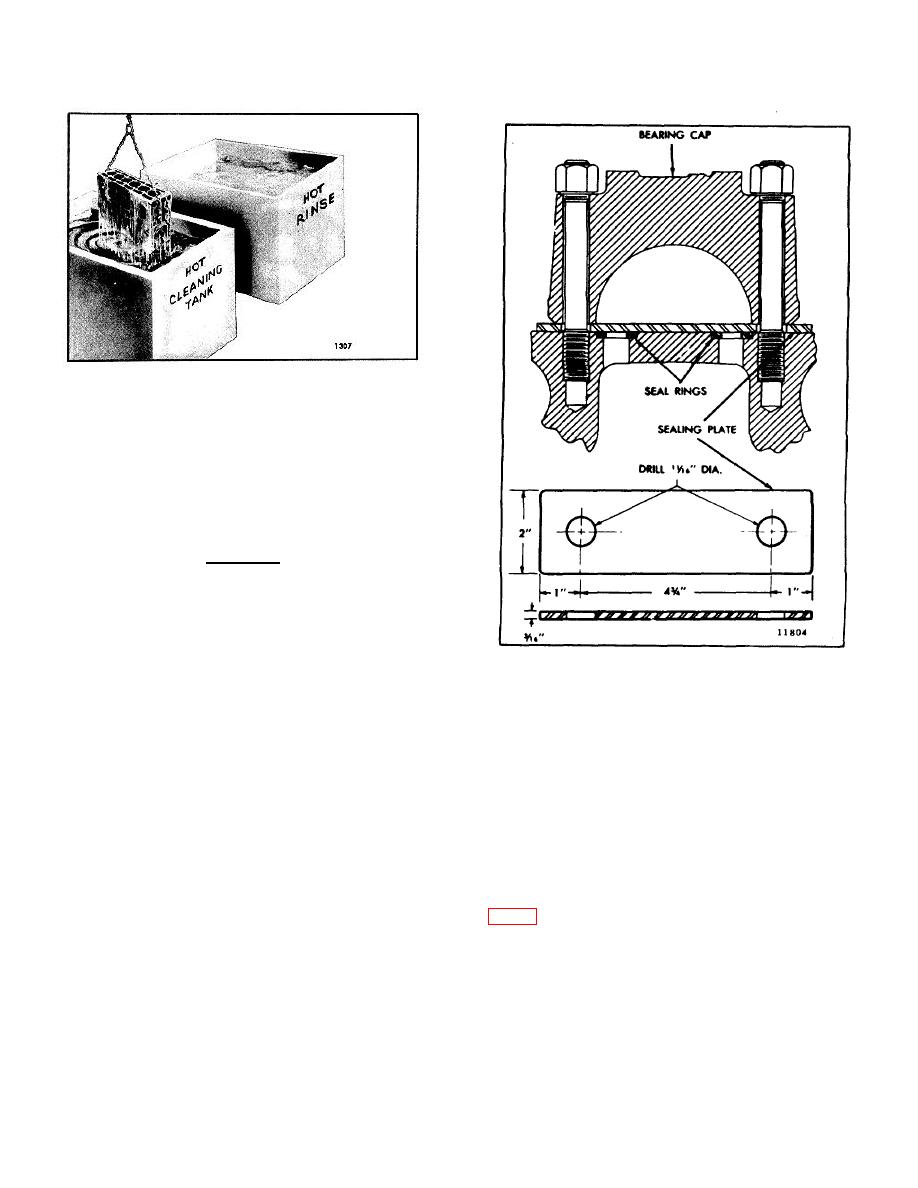

Fig. 8 Sealing Plate Details for Pressure Testing

27.

Place suitable jack under rotor transmission,

Cylinder Block

remove transmission mounting bolts and remove

transmission from engine.

If a core hole plug is difficult to remove, hold a 3/4" drift

against the plug and give it a few sharp blows with a

28. Remove clutch pressure plate mounting bolts and

one-pound hammer. With a I/2 " flexible handle and a

remove clutch assembly from engine flywheel.

short extension placed in the countersunk hole in the

29. Remove cylinder block sub assemblies.

plug, turn the plug slightly in the direction of tightening.

Then turn it in the opposite direction and back the plug

The procedure for removing each sub-assembly from

out.

the cylinder block, together with disassembly,

inspection, repair and re-assembly of each, will be found

Clean the cylinder block as follows:

in the various chapters of this manual.

1. Remove the grease by agitating the cylinder block in

After stripping. the cylinder block must be thoroughly

a hot bath of commercial heavy-duty alkaline solution

cleaned and inspected.

Clean Cylinder Block

2. Wash the block in hot water or steam clean it to

remove the alkaline solution.

Scrape all gasket material from the cylinder block. Then

remove all oil gallery plugs and core hole plugs (except

3. If the water jackets are heavily scaled. proceed as

cup plugs) to allow the cleaning solution to contact the

follows:

inside of the oil and water passages. This permits more

efficient cleaning and eliminates the possibility of the

cleaning solution attacking the aluminum core hole plug

gaskets.

10-2-6