TM 5-3895-359-14&P

Inspect Cylinder Block

After cleaning and pressure testing, inspect the cylinder

block.

Since most of the engine cooling is accomplished by

heat transfer through the cylinder liners to the water

jacket, a good liner-to-block contact must exist when the

engine is operating. Whenever the cylinder liners are

removed from an engine, the block bores must be

inspected.

NOTE: Before attempting to check the

block bores, hone them throughout their

entire length until about 75% of the area

above the ports has been "cleaned-up"

1. Hone the block bores as follows:

a. Use a hone in which the cutting radius of

the stones can be set in a fixed position to

remove irregularities in the bore rather

than following the irregularities as with a

spring-loaded hone. Clean the stones

frequently with a wire brush to prevent

stone loading.

Follow the hone

manufacturer's instructions regarding the

use of oil or kerosene on the stones. Do

not use such cutting agents with a dry

hone. Use 120 grit stones J 5902-14.

b. Insert the hone in the bore (Fig. 10) and

adjust the stones snugly to the narrowest

section. When correctly adjusted, the

hone will not shake in the bore. but will

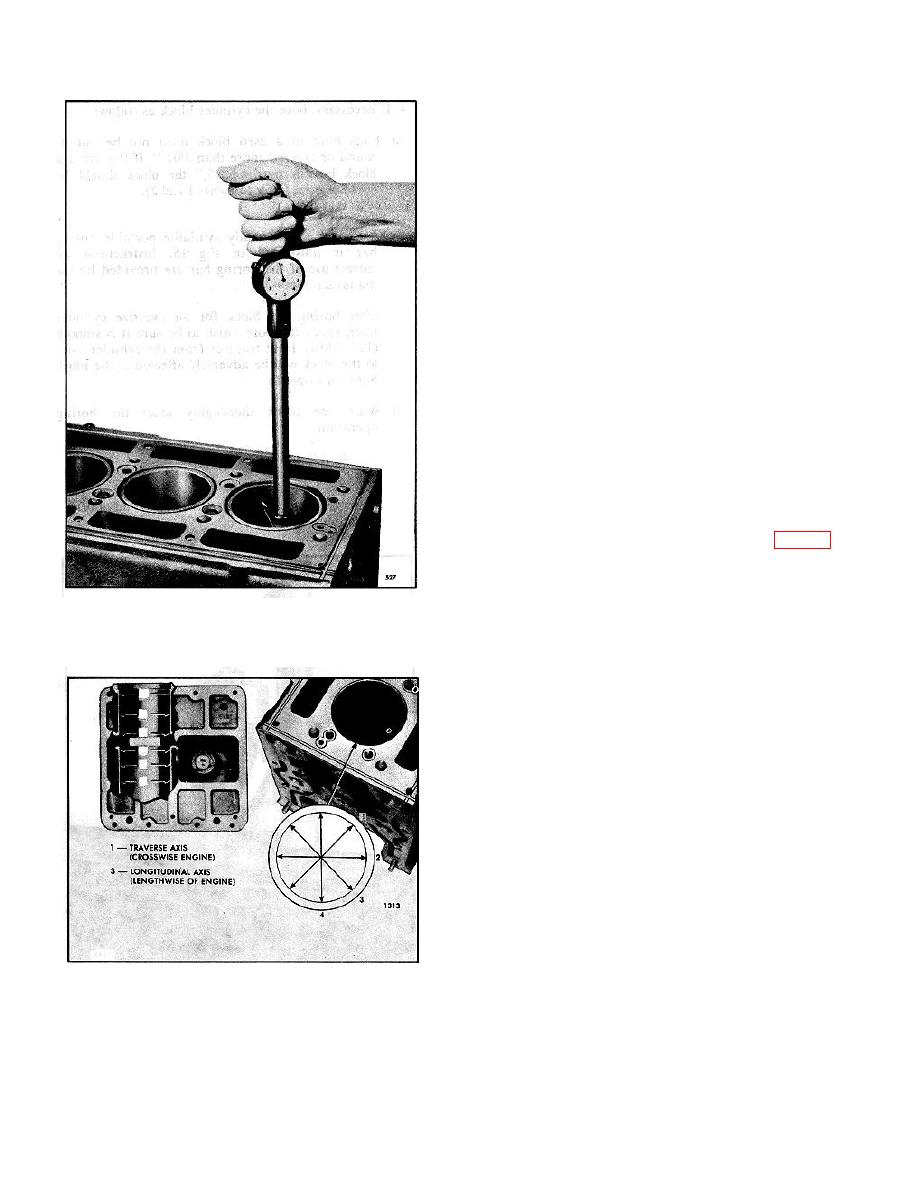

Fig. 12. Checking Bore of Cylinder Block

drag freely up and down when the hone is

not running.

the water jacket and blow out all of the passages in the

c. Start the hone and "feel out" the bore for

block with compressed air.

high spots which will cause an increased

drag on the stones. Move the hone up

and down the bore with short overlapping

strokes about I " long. Concentrate on the

high spots in the first cut. As these are

removed, the drag on the hone will

become lighter and smoother. Do not

hone as long at the air inlet port area as in

the rest of the bore because this area, as

a rule, cuts away more rapidly. Feed

lightly to avoid an excessive increase in

the bore diameter. Some stones cut

rapidly even under low tension.

d. When the bore is fairly clean, remove the

hone, inspect the stones and measure the

bore. Determine which spots must be

honed most. Moving the hone from the

top to the bottom of the bore will not

correct an out-of-round condition. To

Fig. 13. Cylinder Bore Measurement Diagram

remain in one spot too long will cause the

bore to become irregular. Where and how

much to hone can be judged by feel. A

heavy cut in a distorted bore produces a

steady drag on

10-2-9