TM 5-3895-359-14&P

4. If necessary, bore the cylinder block as follows:

the hone and makes it difficult to feel the high

a. Each bore in a used block must not be out-of-

spots. Therefore, use a light cut with frequent

stone adjustments.

round or tapered more than .002 ". If the

average block bore is over 4.6285," the block

e. Wash the cylinder block thoroughly after the

should be bored oversize (refer to Tables 1 and

honing operation is completed.

2).

2. The cylinder liner is alternately expanding and

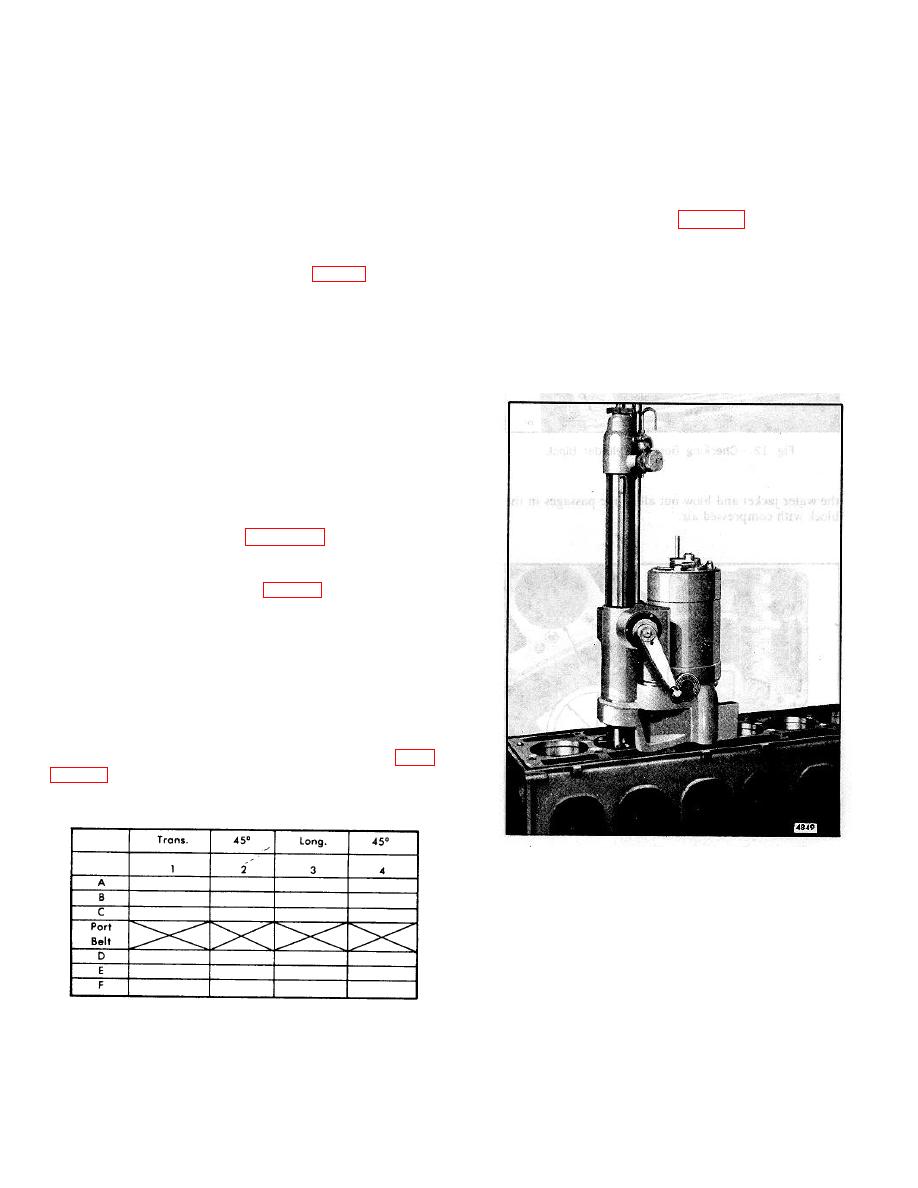

b. A typical commercially available portable boring

contracting, during engine operation.

due to

bar is illustrated in Fig. 15. Instructions on

temperature variations. This may result in irregularities

correct use of the boring bar are provided by the

in the block bores (out-of-round and taper), the effects

manufacturer.

of which will be seen as high pressure areas on the

outside diameter of the cylinder liner (Fig. 11). A slight

c. After boring the block for an oversize cylinder

increase in block bore size is normal with high mileage

liner, check the bore finish to be sure it is

or long period: o)I engine operation.

smooth (120 RMS). Heat transfer from the

cylinder liner to the block will be adversely

a. Visually check the contact area as revealed by

affected if the block bore isn't smooth.

the honed surface. There must not be any low

spots which are larger in area than a half dollar.

d. Wash the block thoroughly after the boring

operation.

b. Measure the entire bore of each cylinder with

cylinder bore gage J 5347-01 (Fig. 12) which

has a dial indicator calibrated in .0001 "

increments. The standard block bore is 4.6260"

to 4.6275." Place the bore gage in the master

ring gage J 8386-01 which has an I.D. of

4.6270" and set the dial to zero.

Take

measurements on the cleaned-up surface only

at positions A, B, C, D, E and F in the bore on

axes 45 apart (Fig.

Read the

measurements from the zero mark on the gage.

The readings may be recorded on a form similar

to the one illustrated in Fig. 14.

NOTE: Dial bore gage setting master

tool J 23059-01 may be used in place of

the master ring gage.

3. The liner-to-block clearance with new parts is zero to

.0015." With used parts, the maximum clearance is

.0025." After measuring the bores, measure the outside

diameter of the cylinder liners (Page 10-2-94). Then

determine the block-to-liner clearances (refer to Page

be necessary to bore the block for oversize cylinder

liners.

Fig. 15. Boring Cylinder Block with Portable Boring

Bar

Fig. 14. Block Bore Measurement Record Form

10-2-10