TM 5-3895-359-14&P

After the cylinder block has been thoroughly cleaned

and dried, re-install the core hole plugs. Coat the

threads of the plugs with sealant. Install the core hole

plugs in the sides of the block from 2 " to 2-1/4" below

the machined surface of the block. They must be water

tight. The core hole plugs in the ends of the block are

flanged to provide a positive stop against the

counterbore of the hole, thus preventing the plugs from

entering the water jacket and restricting the flow of

water. Soft aluminum gaskets are used with the plugs.

Coat the threads of the end plugs with sealant and,

using new gaskets, re-install the plugs and tighten them

to 150-180 lb-ft (204-244 Nm) torque.

CAUTION:

Excessive torque applied to the core

hole plugs may result in cracks in

the water jacket.

Pressure Test

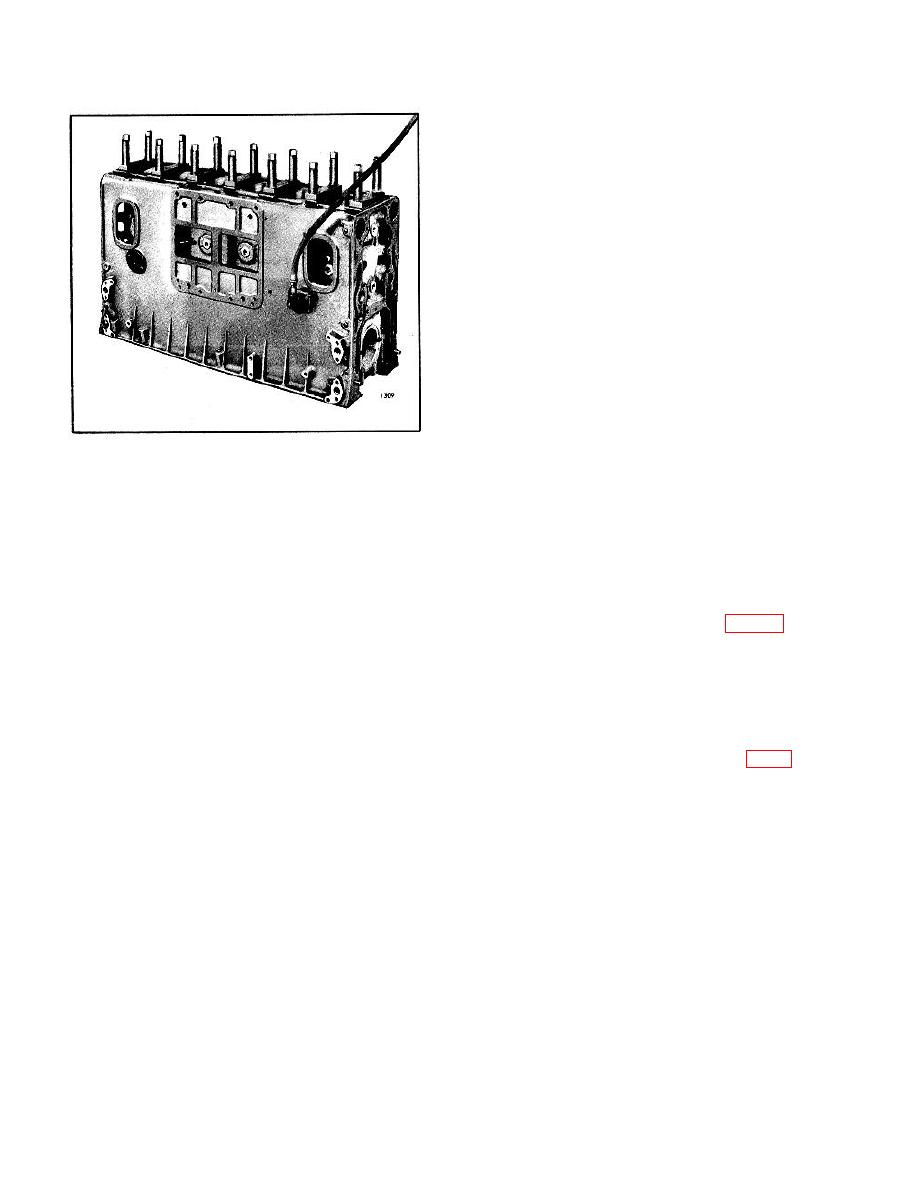

Fig. 9 - Cylinder Block Prepared for Pressure

Test

Cylinder Block Extremely tight fitting cylinder

liners,

a. Agitate the block in a bath of inhibited

severe scoring of the liners and overheating

of the

commercial pickling acid.

engine may result in cracks in the cylinder

bores.

b. Allow the block to remain in the acid bath until

Overheating of the engine may also result in

cracks

the bubbling action stops (approximately 30

between the water jackets and the oil passages.

minutes).

The cylinder block may be pressure tested for cracks or

c. Lift the block, drain it and re-immerse it in the

leaks by either one of two methods. In either method, it

same acid solution for 10 minutes.

will be necessary to make plates (Fig. 8) to seal the

d. Repeat Step "c" until all scale is removed.

water openings in the top of the block. Main bearing

caps may be used to secure the plates to the block with

e. Rinse the block in clear hot water to remove the

the cylinder head bolts or studs and nuts. Cylinder head

acid solution.

seal rings may be used as gaskets between the plates

and the block. It will also be necessary to use water

f. Neutralize the acid that may cling to the casting

hole cover plates and gaskets to cover the water pump

by immersing the block in an alkaline bath.

inlet openings in the block. Drill and tap one cover plate

g. Wash the block in clean water or steam clean it.

to provide a connection for an air line (Fig. 9).

4. Dry the cylinder block with compressed air.

5. Make certain that all water passages, oil galleries

and air box drain holes have been thoroughly cleaned.

NOTE: The above cleaning procedure may

be used on all ordinary cast iron and steel

parts of the engine. Mention will be made

of special cleaning procedures whenever

necessary.

10-2-7