TM 5-3895-369-14

5-90. ROTOR DRIVE ASSEMBLY REPAIR.

This task covers:

c. Assembly

b. Cleaning/Inspection

a. Disassembly

INITIAL SETUP

Materials/Parts

Tools

Studs (12)

Shop equipment, general purpose repair: semi-

Sleeves, thrust (2)

trailer mounted

Rivets (16)

Cloth, lint-free (item 12, appendix E)

Puller, pinion, rotor drive (para F-l, appendix F)

Dye, marking (Prussian Blue) (item 20,

Wrench, torque

Compound, anti-seize (item 13, appendix E)

Lifting device (capacity 500 lb [227 kg])

Personnel Required

MOS62B, Construction equipment repairer (2)

Material/Parts

Locknuts (6)

Equipment Condition

Locknuts, special (2)

TM or Para

Condition Description

Lo&washers (22)

Rotor drive shaft

Lockwashers, special (3)

removed.

Seals (3)

Rotor tine plates

Gaskets (5)

removed.

Packing, preformed (2)

a.

Disassembly.

NOTE

A rotor drive pinion puller is required for

this task and must be fabricated (para F-l,

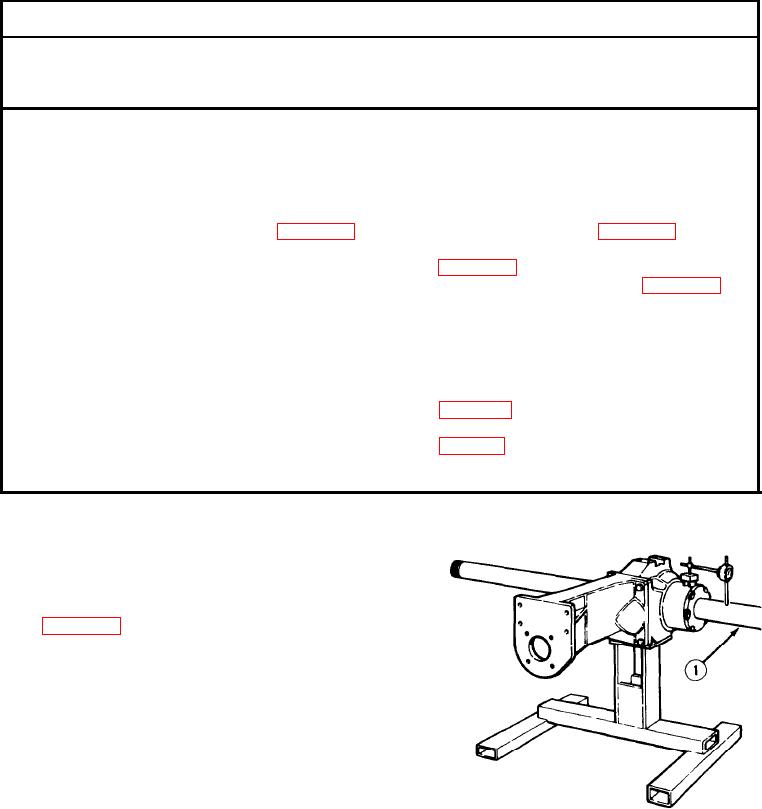

(1) Check ring gear and pinion backlash with

dial indicator on axle (1). Move axle back

and forth to measure backlash. Record

measurement.

5-526