TM 5-3895-369-14

(5) Check sealing surfaces for nicks, burrs, or other damage.

(6) Check machined surfaces for damage.

(7) Check backplate, case, and faceplate for cracks or other damage.

(8) Check shafts for nicks, burrs, excessive wear, or scoring.

(9) Check sleeve bearings for scoring, galling, nicks, excessive wear, or any other damage.

(10) Check threads for peeled or crossed condition.

(11) Replace damaged parts.

c.

Assembly.

NOTE

Aline new or existing sleeve bearing

oil grooves with oil grooves in

faceplate.

If installing new sleeve bearings, do

step (1). If sleeve bearings are not

replaced, go to step (2).

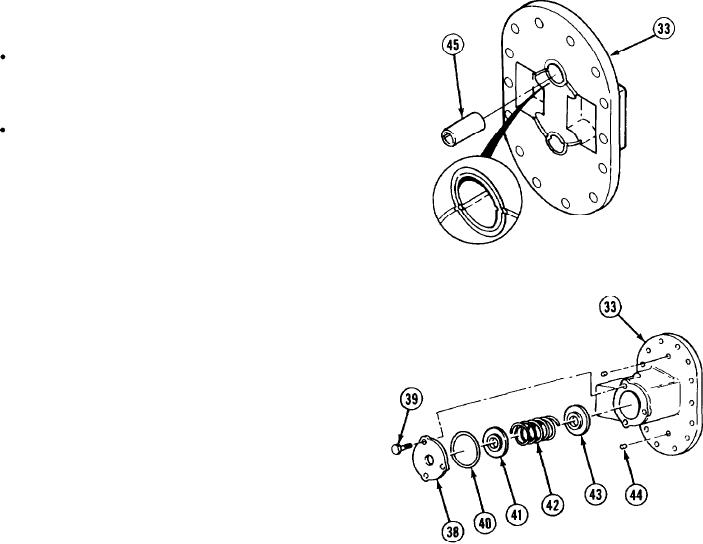

(1) Install and notch two bearing sleeves (45) to

depth of faceplate (33) oil grooves.

(3) Install two pipe plugs (44) in faceplate (33).

(4) Install poppet and guide (43) spring (42),

and poppet and guide (41) in faceplate (33).

(5) Install preformed packing (40) in plug

cap (38).

(6) Install plug cap (38) with three screws (39).

Tighten screws 35 lb-ft (47 N m).

5-521