TM 5-3895-369-14

(a) Loosen adjusting ring (36) five or six notches.

(b) Tighten adjusting ring (35) one notch.

(c) Tighten adjusting ring (36) until adjusting ring resists movement, then tighten two or three more

notches. Check for correct backlash.

NOTE

If the backlash tolerance does not vary more than 0.002 inch (0.050 mm), the setting is acceptable.

(35) Tighten four bearing cap screws (34) 150 to 160 lb-ft (200 - 220 Nm).

(36) Paint l/3 of teeth on ring gear (14) with Prussian Blue dye.

(37) Roll ring gear (14) l/3 turn, then rock ring gear forward and backward to set pattern in dye,

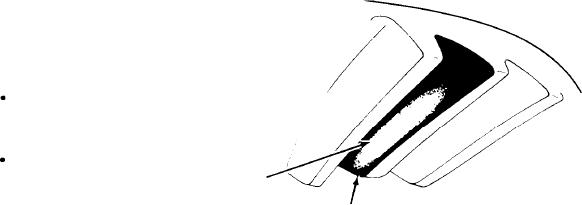

CORRECT PATTERN (NEW GEARING)

COULD VARY IN LENGTH. PATTERN

SHOULD COVER 1/2 TOOTH OR MORE

(FACE WIDTH).

PATTERN SHOULD BE EVENLY

CENTERED BETWEEN TOOTH TOP

LAND AND ROOT.

. PATTERN SHOULD BE CLEAR OF TOOTH TOE.

PATTERN A

NOTE

.

A correct gear pattern for a used pinion and ring gear is clear of the toe and centers evenly along the

face of gear tooth, but can be any length and shape and is acceptable as long as pattern does not run

off gear tooth at any point.

.

If gear pattern was correct at disassembly, then gear pattern after assembly should be the same.

.

If pattern is not the same, review steps (32) through (34) and adjust backlash as required until

pattern that was recorded at disassembly is reached.

.

If pattern was incorrect (pattern runs off gear tooth) at disassembly then, after assembly, review

steps (32) through (34) and adjust backlash as required until correct gear pattern (pattern does not

run off gear teeth) is reached.

.

Remember, a correct gear pattern for a used pinion and ring gear does not have to match PATTERN

A (correct pattern for new gearing).

.

If new pinion and ring gear are used, tooth pattern should be like correct PATTERN A. If tooth

pattern does not look like A, check patterns B through E to find one that looks close to ring gear

tooth pattern, then do step that follows incorrect pattern.

(38) If tooth contact is like pattern A, do not adjust. Go to step (43).

5-413