TM 6-3895-369-14

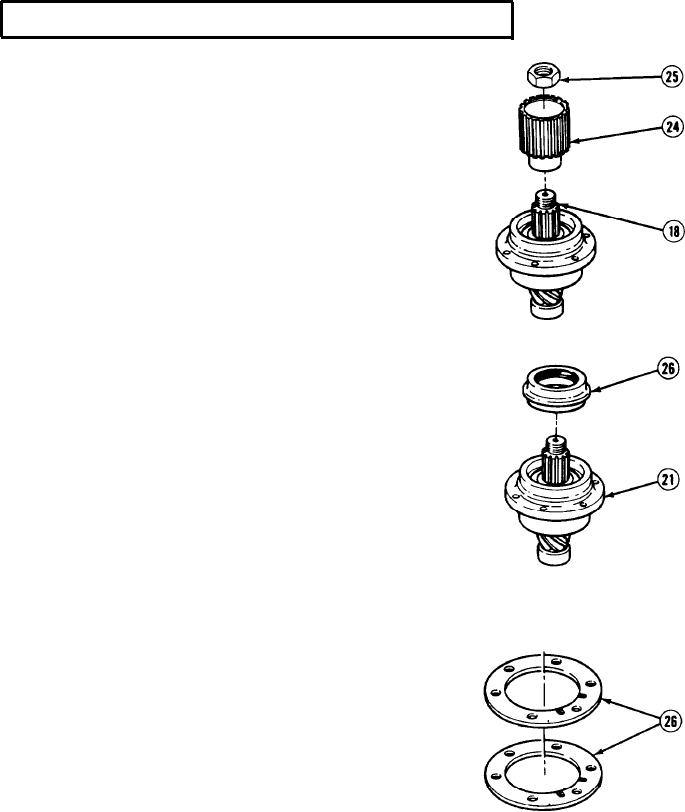

5-69. DIFFERENTIAL ASSEMBLY REPAIR (CONT).

(18) After obtaining spring scale reading of

5 to 14 lbs (2.3 - 6.4 kg), remove pinion

nut (25) and axle input gear (24) from

pinion shaft (18).

(19) Install oil seal (26) in bearing retainer

cap (21).

NOTE

.

If original ring and pinion gear set is

reused, install the same shims as

removed and go to step (23). If new

gear set is used, continue with

step (20).

.

Replace old pinion shims if bent or

mutilated.

(20) Measure thickness of each old pinion

shim (26) separately. Add measurements to

get total thickness of original build-up.

5-408