TM 5-3895-369-14

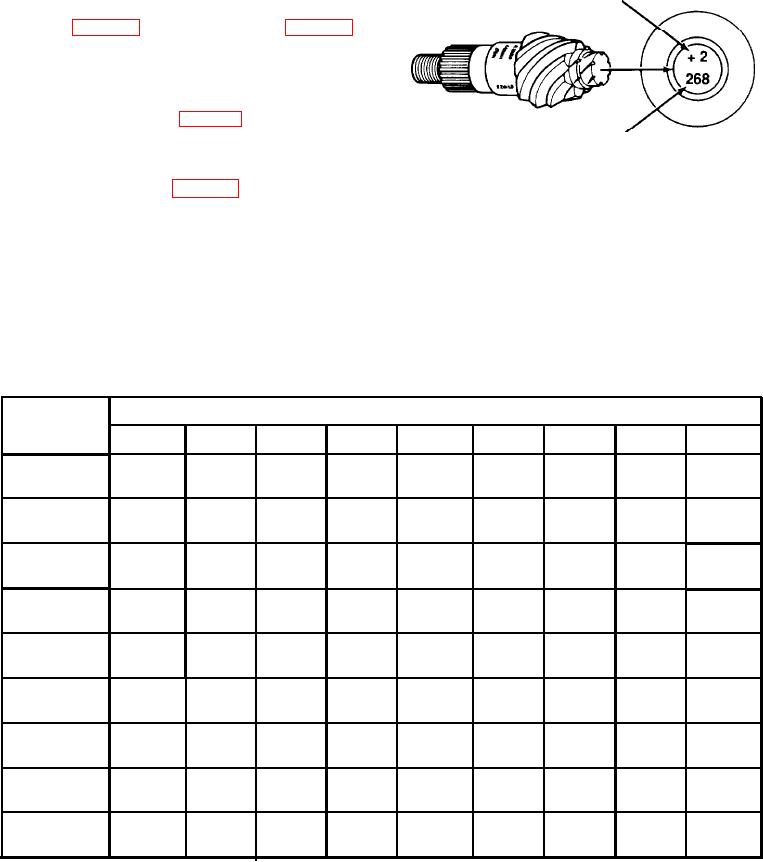

(21) Note +, -, or 0 etched on bottom of both

new and original ring and pinion gear sets.

Adjust shim thickness to compensate for the

PINION ETCH

difference between both figures as shown in

Table 5-4, Pinion Markings. Use Table 5-4

as follows:

(a) Locate +, -, or 0 number, from bottom

of original pinion shaft, in appropriate

column in Table 5-4.

MATCHED SET

(b) Locate +, -, or 0 number, from bottom

NUMBER

of new pinion shaft, in appropriate

column in Table 5-4.

(c) Find the box where original and new

numbers intersect.

(d) Either add to, or subtract from, original shim build-up as recorded in step (20). For example: If

the original pinion shaft is etched +2, and new pinion shaft is etched -1, subtract 0.003 inch

(0.076 mm) from total thickness of original shims. Remove or replace shims as appropriate.

Table 5-4. Pinion Markings

Old Pinion

New Pinion Marking

+1

+2

Marking

-1

0

+4

+3

-3

-2

-4

-0.003

-0.005

-0.004

-0.002

-0.001

-0.006

-0.008

-0.007

+4

0

.076

.051

.025

.127

.102

.178

.152

.203

-0.002

+0.001

-0.004

-0.003

-0.005

-0.001

-0.007

-0.006

0

+3

.051

.102

.076

.152

.127

.025

.178

.025

-0.001

+0.001

-0.003

-0.002

-0.004

+0.002

-0.006

- 0.005

0

+2

.025

.076

.051

.025

.051

.127

.102

.152

+0.001

+0.002

-0.002

-0.001

+0.003

-0.003

-0.005

-0.004

0

+1

.051

.025

.127

.076

.102

.025

.051

.076

+0.001

+0.002

+0.003

+0.004

-0.001

-0.002

-0.004

-0.003

0

.025

.025

0

.051

.076

.102

.076

.051

.102

+0.002

+0.001

+0.003

+0.004

+0.005

-0.001

-0.003

-0.002

-1

.051

O

.025

.076

.102

.05 1

.025

.127

.076

- 0.002

-0.001

+0.001

+0.002

+0.003

+0.004

+0.005

+0.006

-2

0

076

.025

.051

.102

.127

.152

.025

.051

+0.001

+0.002

+0.003

+0.004

+0.006

-0.001

+0.005

+0.007

-3

0

.127

.152

.102

.051

.076

.178

.025

.025

+0.005

+ 0.004

+0.006

+0.007

+0.003

+0.002

+0.008

+0.001

-4

0

.127

.076

.102

.152

.178

.203

.025

.051

0.000 TOP (INCHES)

.000 BOTTOM MM)

5-409