TM 5-3895-369-14

Compressed air used for cleaning purposes must not exceed 30 psi (207 kPa). Use only with effective

chip guarding and personal protective equipment (goggles/shield, gloves, etc).

(2) Use lint-free cloth or compressed air to dry all metal parts except bearings.

(3) Allow bearings to air dry.

(4) Clean all sealing surfaces.

(5) Check all machined surfaces for damage.

(6) Check both case halves for cracks or damage.

(7) Check all threads for peeled or crossed condition.

(8) Replace all oil seals and damaged parts.

(9) Apply petroleum jelly to preformed packing and seals prior to installation.

(10) Replace control kit, if damaged.

c.

Assembly.

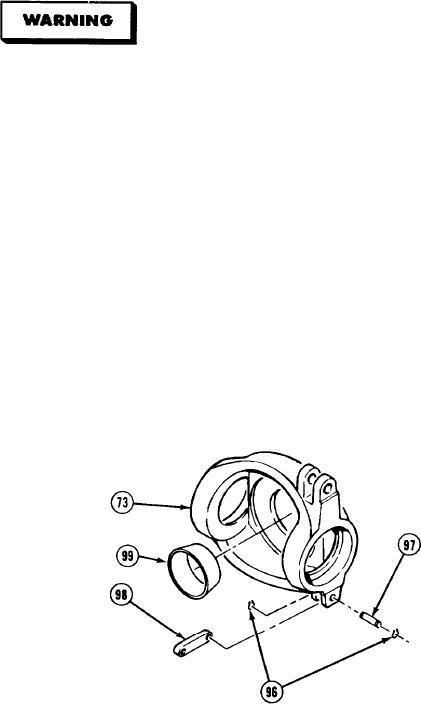

(1) Install bearing race (99) and feedback

links (98) in swash plate (73) with pins (97)

and two retaining rings (96).

5-331