TM 5-3895-359-14&P

Revolve the pump shaft bearing slowly by hand.

NOTE:

Replace the shaft and bearing assembly and the seal

Do not mar the polished surface of

assembly.

the ceramic insert.

Inspect the ceramic insert for cracks, scratches and

3. Place the impeller assembly in a level position, with

bond to the impeller. If the insert is damaged, replace it

the ceramic insert up, in an oven preheated to 350

F

as follows:

(177 ) and bake it for one hour.

C

1. Bake the insert and impeller assembly at 500

F

NOTE:

(260C) for one hour. The insert can be removed easily

The face of the ceramic insert must

while the adhesive is hot. After removing the insert,

be square with the axis of the

clean the insert area on the impeller with sandpaper,

tapered bore within .004". The pump

wire brush or a buffing wheel to remove the old

shaft may be used as a mandrel for

adhesive, oxide, scale, etc.

inspection.

2. Examine the studs in the pump body. If it is

4. Remove the impeller from the oven and, after it has

necessary to replace a stud, use a good grade of sealant

cooled to room temperature, install it in the pump. Do

on the threads and drive the stud in to 6-8 lb-ft (8-11

not loosen the clamping bolt until the assembly cools.

Nm) torque.

Make sure the mating surfaces of the water seal and the

ceramic insert are free of dirt, metal particles and oil

Assemble Water Pump

film.

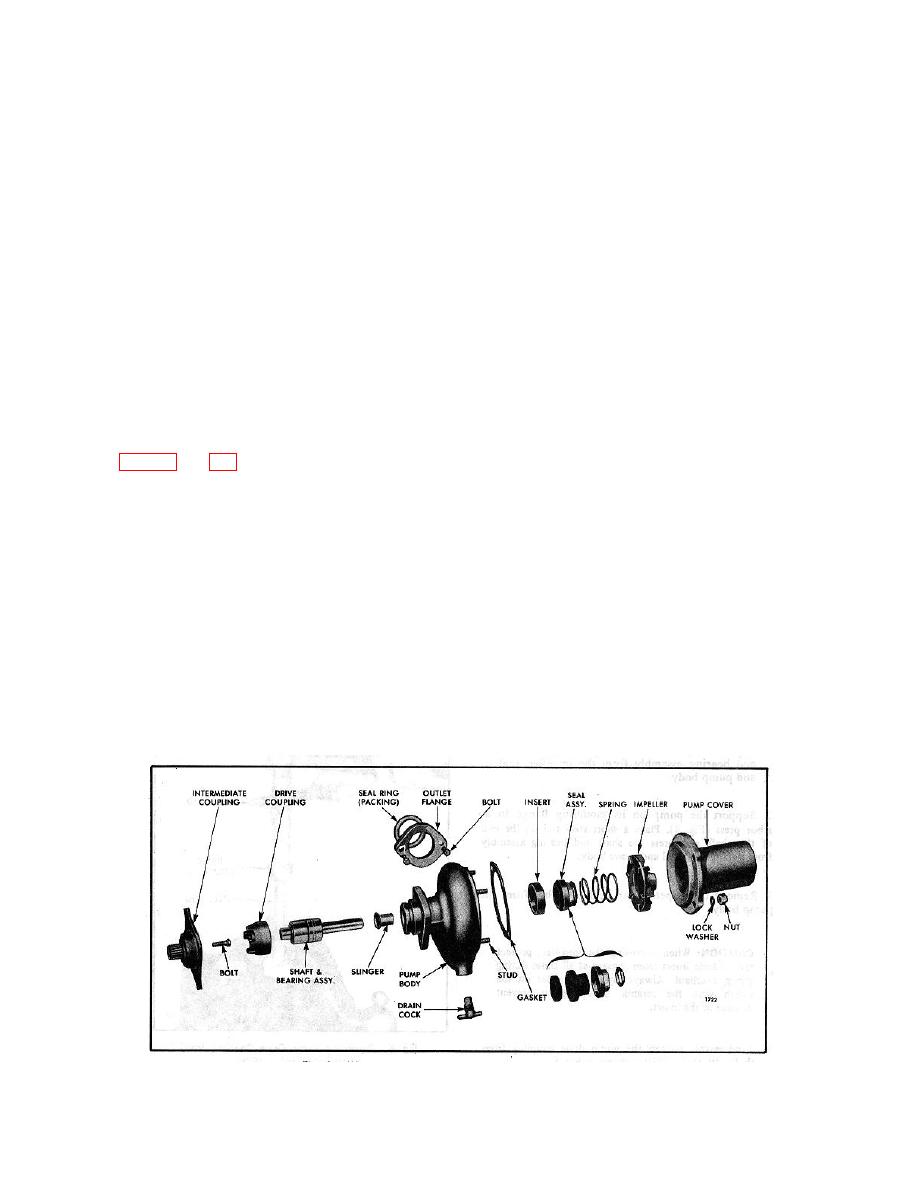

Refer to Figs.

5. Support the impeller end of the pump body on an

follows:

arbor press and insert the coupling end of the shaft and

bearing assembly into the pump body. Then press

1. Wet a clean cloth with a suitable solvent such as

against the outer race of the bearing until the bearing

alcohol and thoroughly clean the impeller insert area

contacts the shoulder in the pump body.

and the grooved side of a new ceramic insert. Then

wipe the parts with a clean, dry cloth.

NOTE:

When installing the shaft and bearing

2. Place the adhesive washer in the impeller bond area

assembly, it will not be necessary to

with the ceramic insert on top. The polished face of the

stake the end of the pump body.

ceramic insert should be visible to the assembler.

Clamp the insert and impeller together with a 3/8" bolt

6. With the surface of the pump seal clean and free

and nut and two smooth .125" thick washers. Tighten

from dirt and metallic particles, apply a thin coat of

the bolt to 10 lb-ft (14 Nm) torque.

liquid soap on the inside diameter of the rubber seal. To

reduce possible coolant leakage, apply a light coat of

non-hardening sealant on the outside diameter of a

Fig. 6 - Water Pump Details and Relative Location of Parts

10-6-8