TM 5-3895-359-14&P

6.

Start and run the engine for a short period and

check for oil leaks. After any oil leaks have been

corrected and the engine has been stopped long enough

for oil from the various parts of the engine to drain back

to the crankcase (approximately 20 minutes), add

sufficient oil to raise the oil level to the proper mark on

the dipstick.

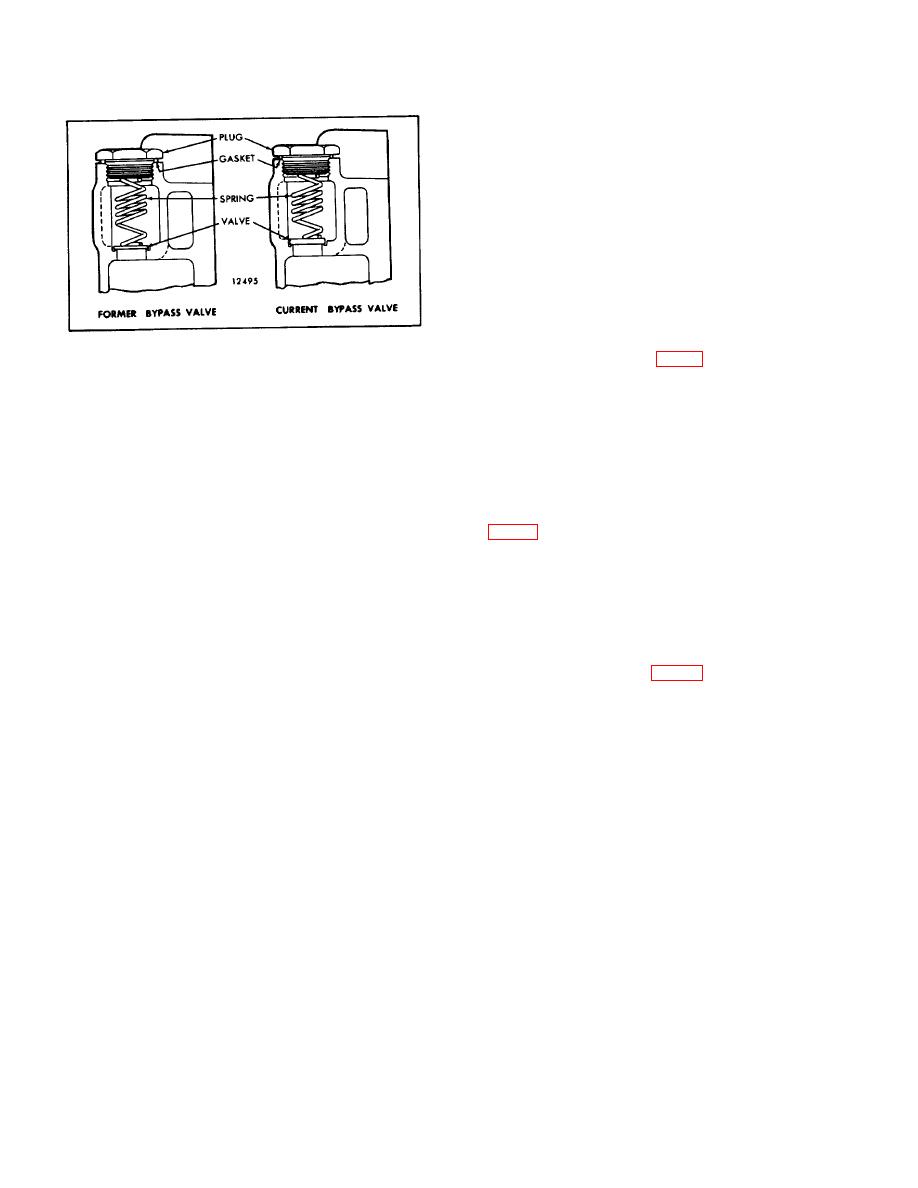

Remove and Install Bypass Valve

1.

If necessary, remove the filter adaptor from the

engine.

2.

Remove the plug and gasket and withdraw the

spring and bypass valve (Fig. 2).

Fig. 3- Bypass Valve

3.

Wash all of the parts in clean fuel oil and dry

Replace Spin-On Filter

them with compressed air.

1.

Remove the oil filter using strap wrench tool J

4.

Inspect the parts for wear. If necessary, install

24783 which must be used with a 1/2" drive socket

new parts.

wrench and extension.

5.

Reassemble and install the bypass valve. Use

2.

Discard the used oil filter.

only the current bypass valve and spring for service

3.

Clean the filter adaptor with a clean, lint-free

increase the bypass pressure from 13-18 psi to 18-21

cloth.

psi (90-124 kPa to 124-145 kPa) to permit more efficient

filtration. Tighten the 1 1/4"-16 bypass valve plug to 95-

4.

Lightly coat the oil filter gasket (seal) with clean

105 lb-ft (129-143 N ) torque.

m

engine oil.

NOTE:

5.

Start the new filter on the adaptor and tighten by

The current and early design bypass valves are not

hand until the gasket touches the mounting adaptor

interchangeable (inset, Fig. 2).

head. Tighten an additional two-thirds turn.

6.

Use a new gasket and install the filter adaptor.

CAUTION:

Mechanical tightening will distort or crack the filter

adaptor.

10-5-15