TM 5-3895-359-14&P

LUBRICATING OIL FILTER

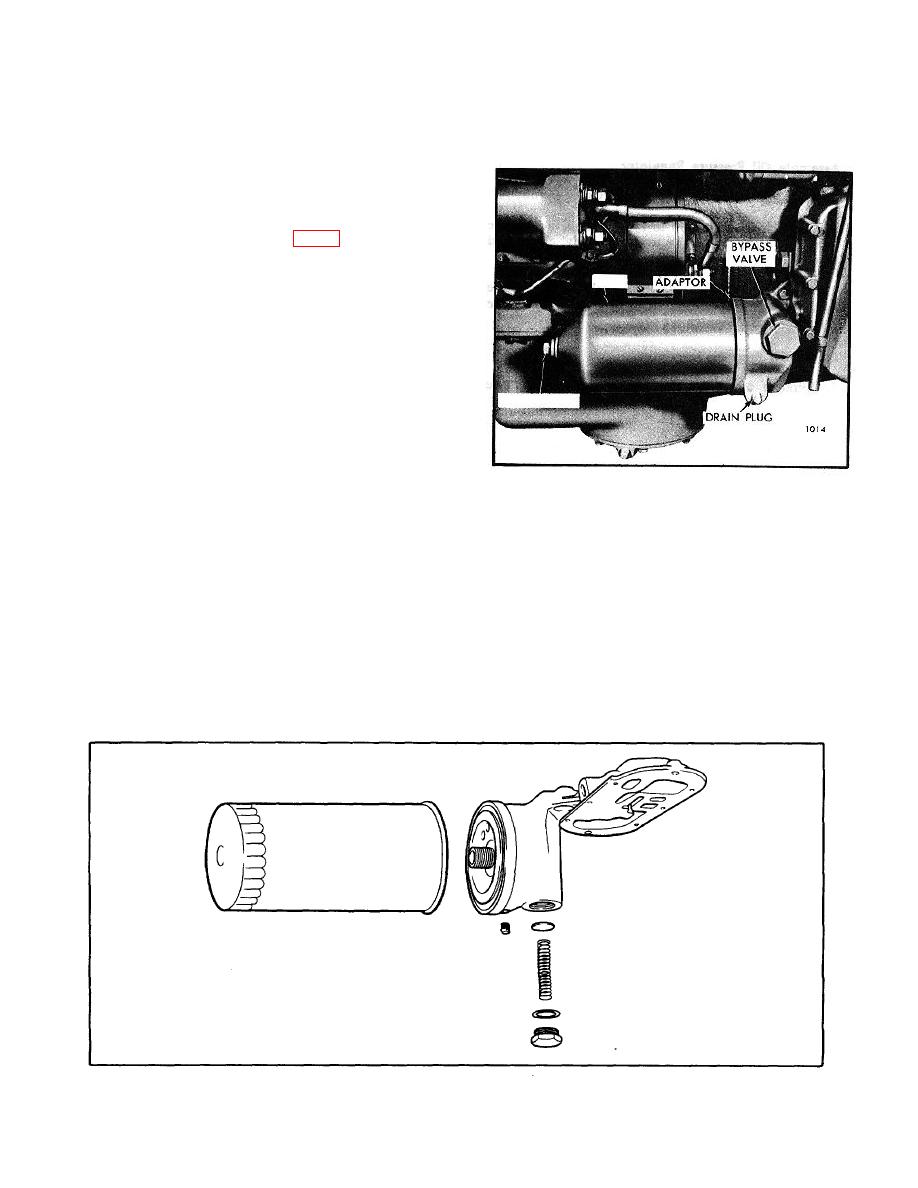

Spin-On Oil Filter

A spin-on type oil filter is installed ahead of the oil cooler

in the lubrication system. The filter is mounted on the

oil cooler adapter plate as shown in Fig. 2.

All of the oil supplied to the engine by the oil pump

passes through the filter before reaching the various

moving parts of the engine. The oil is forced by pump

pressure through a passage in the filter adapter to the

filter. Impurities are filtered out as the oil is forced

through the filter and out through another passage in the

filter adapter and then to the oil cooler.

A valve, which opens at approximately 18-21 psi

(124145 kPa), is located in the filter adapter or base and

will bypass the oil directly to the oil cooler should the

filter become clogged.

Fig. 1 - Typical Oil Filter Mounting.

Oil Filter Maintenance

With the use of detergent lubricating oils, the color of

the lubricant has lost value as an indicator of oil

should be shortened. The removal of abrasive dust,

cleanliness or proper filter action. Due to the ability of

metal particles and carbon must be ensured by

the detergent compounds to hold minute carbon

replacement of the oil filter cartridges at the time the

particles in suspension, heavy duty oils will always

engine oil is changed.

appear dark colored on the oil level dipstick.

Selection of a reliable oil supplier, strict observation of

Heavy sludge deposits found in the filter cartridges at

his oil change period recommendations and proper filter

the time of an oil change must be taken as an indication

maintenance will ensure trouble-free lubrication and

that the detergency of the oil has been exhausted.

longer engine life.

When this occurs, the oil drain interval

Fig. 2 - Full-Flow Oil Filter Details and Relative Location of Parts.

10-5-14