TM 5-3895-359-14&P

the pump driving gear from the front end of the

crankshaft as follows:

a. Screw the crankshaft pulley retaining bolt into the

end of the crankshaft.

b. Place the jaws of the puller behind the gear and

locate the point of the puller screw in the center of

the retaining bolt.

c. Turn the puller screw clockwise and draw the gear

from the crankshaft.

4. Remove the Woodruff key from the crankshaft.

Install Oil Pump Driving Gear on Crankshaft

1. Install the Woodruff key in the crankshaft.

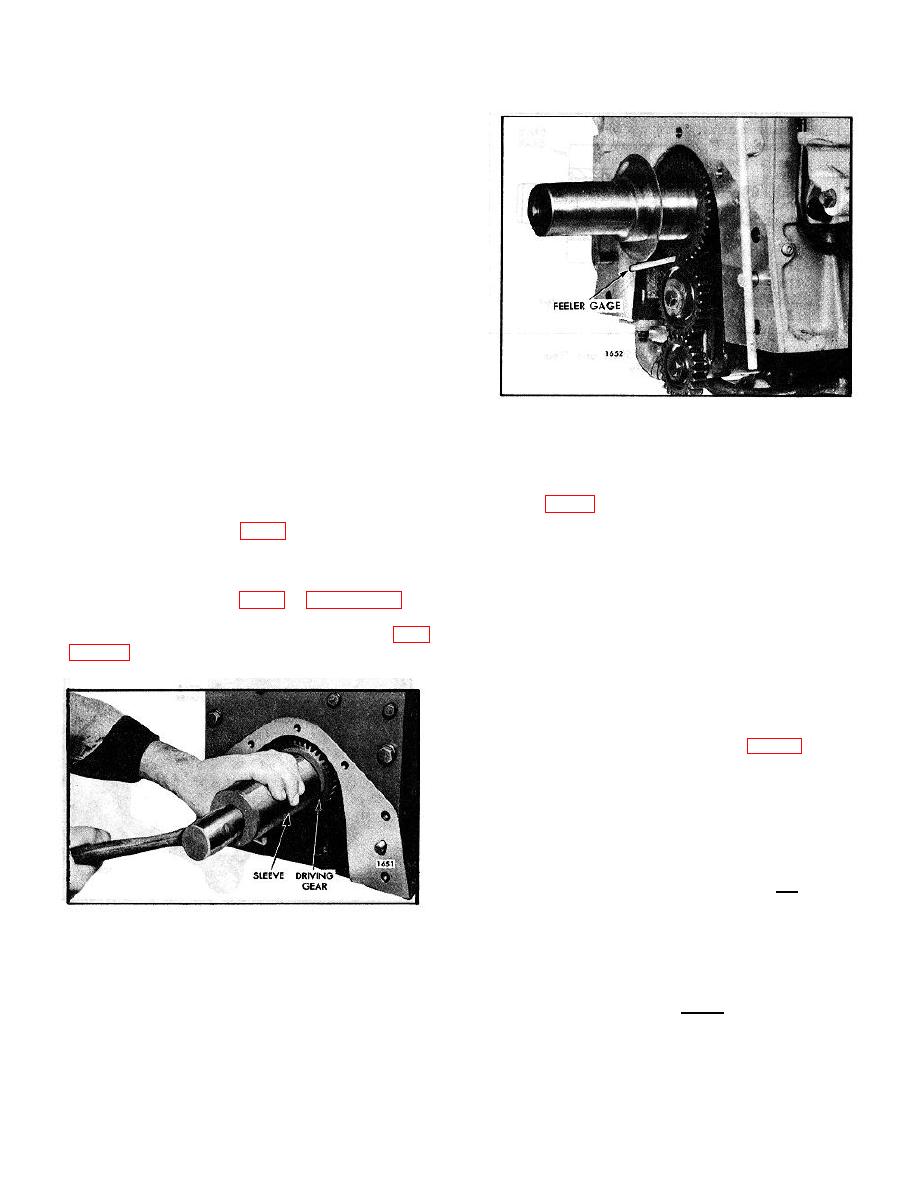

Fig. 10 - Measuring the Clearance Between the

Teeth of the Oil Pump Driven Gears.

2. Position the gear (80) so the chamfer on the gear

hub is toward the main bearing cap and start the gear

Install Oil Pump

on the shaft and over the key.

Refer to Fig. 2 and install the oil pump on the main

3. Slide the gear on the crankshaft or use a sleeve if

bearing caps as follows:

required, as illustrated in Fig. 9, and drive the gear

tight against the shoulder on the crankshaft.

1. Hold the pump assembly against the main bearing

caps so the idler gear (56) meshes with the driving

4. Install the oil slinger with the dished side away from

gear on the crankshaft.

the gear as illustrated in Fig. 1 on Page 10-2-66.

2. Insert the four bolts (55) with lock washers through

5. Install the crankshaft front cover as outlined on Page

the mounting feet of the pump and into the bearing

caps (39). Align the pump so that the teeth of

crankshaft gear and the idler gear are parallel; then

tighten the bolts to 35-39 lb-ft and check clearance

between the gear teeth with a feeler gage. Proper

clearance between the crankshaft gear and idler gear

is .005" minimum, .012" maximum (Fig. 10).

NOTE: Always check the clearance between

the crankshaft gear and the oil pump idler gear

with the engine in the upright or running

position.

If shims were used between the pump mounting feet

and the bearing caps and new gears are not installed,

the same shims (cleaned) or the same number of new

(identical) shims should be installed and the number

Fig. 9 - Installing Oil Pump Driving Gear on

then adjusted to obtain the proper clearance between

Crankshaft.

gear teeth. However, if new gears have been installed,

a larger number of shims will be required under the

mounting feet. In either event, the pump must be

tightened on the bearing cap before

10-5-10