TM 5-3895-359-14&P

OIL COOLER

In order to perform its functions satisfactorily, the

Remove Lubricating Oil Cooler

lubricating oil must be kept within the proper

temperature limits. If the oil is too cold, it will not flow

I.

Drain the cooling system by opening the drain

freely. If the oil is too hot, it cannot support the bearing

valve at the bottom of the oil cooler housing (Fig. 1).

loads, it cannot carry away enough heat, and it may

result in too great an oil flow. As a consequence, oil

2.

Remove the bolts and lock washers that attach

pressure may drop below acceptable limits and oil

the water inlet connector to the oil cooler housing.

consumption may become excessive.

3.

Loosen the clamp on the water pump inlet seal.

In performing its lubricating and cooling functions, the oil

absorbs a considerable amount of heat and this heat

4.

Remove the bolts attaching the oil cooler

must be dissipated by an oil cooler.

housing to the adaptor, and remove the housing and

core as an assembly. Be careful when withdrawing the

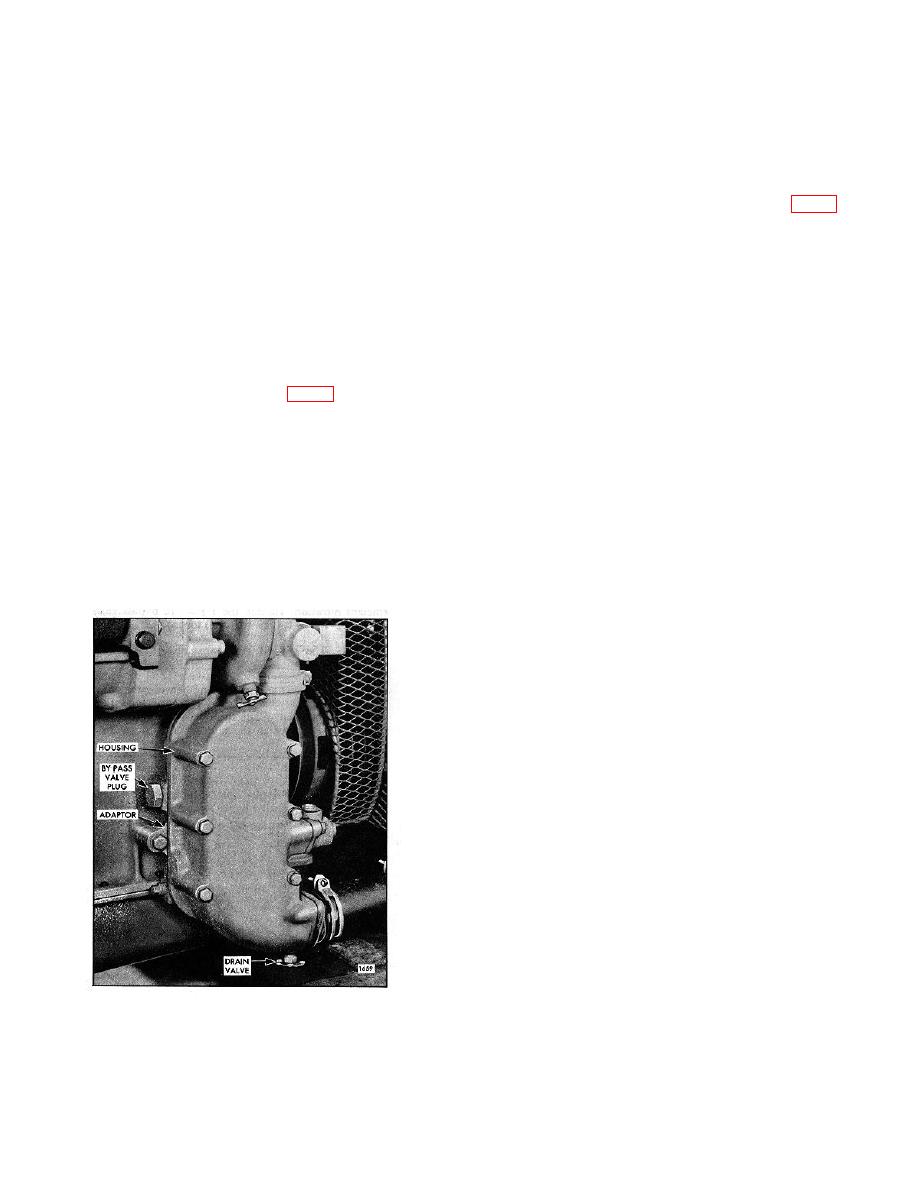

The lubricating oil cooler is located on the side of the

assembly not to drop or damage the oil cooler core.

engine just below the water pump (Fig. 1).

5.

Remove all traces of gasket material from the

To assure engine lubrication if the oil cooler becomes

oil cooler components.

clogged, a bypass valve located at the oil inlet to the

cooler bypasses oil around the cooler directly to the oil

6.

If the core openings are not marked IN and

gallery in the cylinder block.

OUT, mark the openings.

The core through which the oil passes while being

7.

If the adaptor is to be removed, remove the

cooled is sealed to prevent coolant from getting into the

bolts that hold the adaptor to the cylinder block and

oil. Whenever an oil cooler is assembled, special care

remove the adaptor and gaskets.

must be taken to have the proper gaskets in place and

the retaining bolts tight.

8.

Clean the oil cooler core as outlined under

Clean Oil Cooler Core.

9.

Pressure check the oil cooler core as outlined

under Pressure Check oil Cooler Core.

Clean Oil Cooler Core

1.

Clean Oil Side of Core - Circulate a solution of

trichloroethylene through the core passages with a force

pump to remove carbon and sludge.

WARNING

This operation should be done in the open or in a

well ventilated room when trichloroethylene or other

toxic chemicals are used for cleaning.

Clean the core before the sludge hardens. If the oil

passages are badly clogged, circulate an Oakite or

alkaline solution through the core and flush thoroughly

with clean hot water.

2.

Clean Water Side of Core - After cleaning oil

side of the core, immerse it in the following solution:

add one-half (1/2) pound of oxalic acid to each two and

Figure 1. Typical Lubricating Oil Cooler

one-half (2 1/2) gallons of solution composed of one-

Mounting-Radiator Cooled Engine

third (1/3) muriatic acid and two-thirds (2/3) water.

The cleaning action is evidenced by bubbling and

10-5-16