TM 5-3895-359-14&P

FUEL PUMP

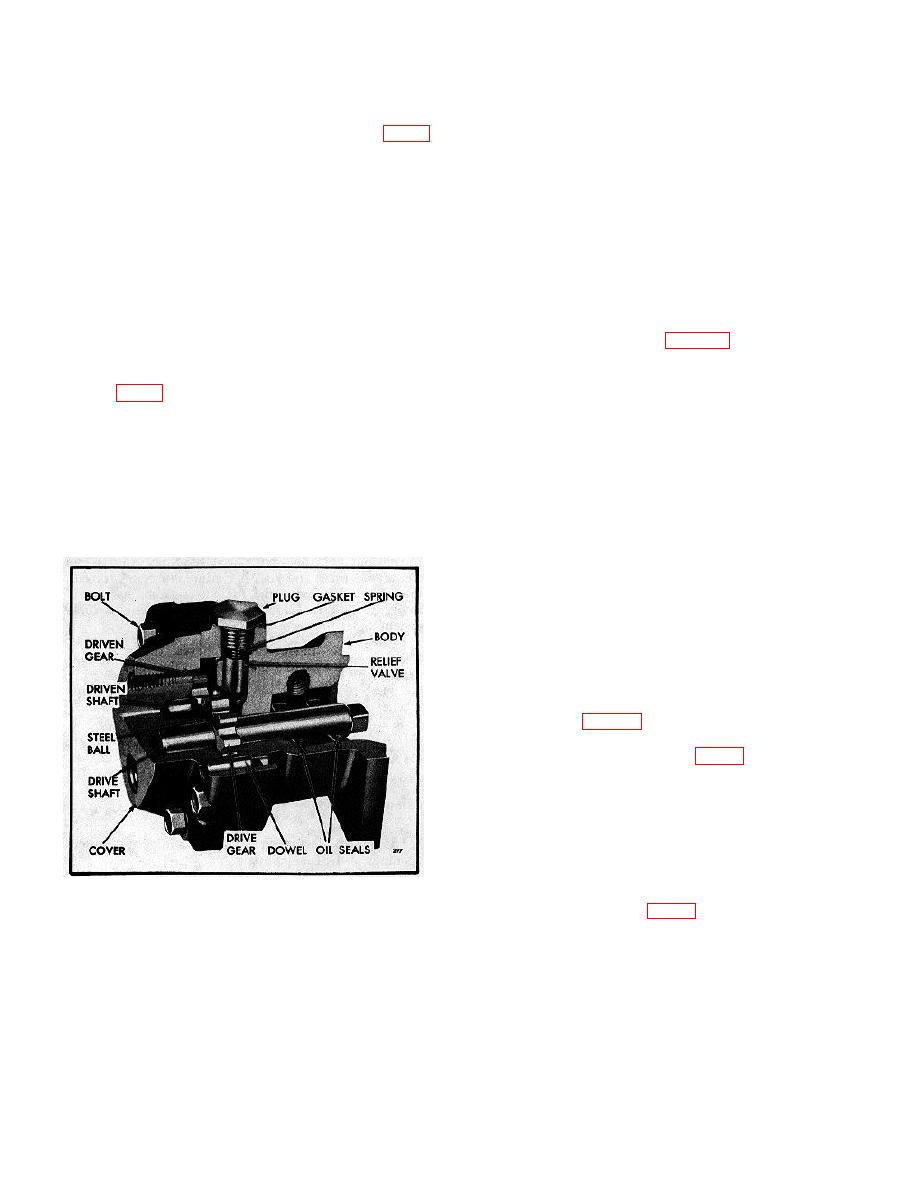

The positive displacement gear-type fuel pump (Fig. 1)

The fuel pump cover and body are positioned by two

transfers fuel from the supply tank to the fuel injectors.

dowels. The dowels aid in maintaining gear shaft

The pump circulates an excess supply of fuel through

alignment. The mating surfaces of the pump body and

the injectors which purges the air from the system and

cover are perfectly flat ground surfaces. No gasket is

cools the injectors. The unused portion of fuel returns to

used between the cover and body since the pump

the fuel tank by means of a fuel return manifold and fuel

clearances are set up on the basis of metal-to-metal

return line.

contact. A very thin coat of sealant provides a seal

against any minute irregularities in the mating surfaces.

The fuel pump is attached to the rear end plate cover of

Cavities in the pump cover accommodate the ends of

the blower assembly with three nylon patch bolts which

the drive and driven shafts.

prevents the oil in the blower cover from seeping out

around the bolt threads. The pump is driven off the end

The fuel pump body is recessed to provide running

of the blower lower rotor by means of a drive coupling

space for the pump gears (Fig. 3). Recesses are also

fork attached to the end of the pump drive shaft and

provided at the inlet and outlet positions of the gears.

mating with a drive disc attached to the blower rotor as

The small hole "A" permits the fuel oil in the inlet side of

shown in Fig. 2.

the pump to lubricate the relief valve at its outer end

and to eliminate the possibility of a hydrostatic lock

which would render the relief valve inoperative.

Fuel pumps are furnished in left-hand or right-hand

Pressurized fuel contacts the relief valve through hole

rotation. Since the engine is right-hand rotation, a right-

"B" and provides for relief of excess discharge

hand pump is used' and is stamped "RH IN". These

pressures. Fuel reenters the inlet side of the pump

pumps are not interchangeable, nor can a pump made

through hole "C" when the discharge pressure is great

for one rotation be rebuilt for the other rotation since the

enough to move the relief valve back from its seat. Part

relief valve can be installed in only one position in the

of the relief valve may be seen through hole "C". The

pump body.

cavity "D" provides escape for the fuel oil which is

squeezed out of the gear teeth as they mesh together on

the discharge side of the pump. Otherwise, fuel trapped

at the root of the teeth would tend to force the gears

apart, resulting in undue wear on the gears, shafts, body

and cover.

Two oil seals are pressed into the bore in the flanged

side of the pump body to retain the fuel oil in the pump

and the lubricating oil in the blower timing gear

compartment (Fig. 4). The oil seals are installed with

the lips of the seals facing toward the flanged end of the

pump body. A small hole "E" (Fig. 3) serves as a vent

passageway in the body, between the inner oil seal and

the suction side of the pump, which prevents building up

any fuel oil pressure around the shaft ahead of the inner

seal.

However, in this application, where the fuel supply tank

is mounted at a level higher than the fuel pump on the

Fig. 1 - Typical Fuel Pump Assembly

engine, the inner seal is installed with the lip of the seal

facing the gear pocket (Fig. 4). In this case, the inner

seal will prevent seepage of fuel oil along the pump

shaft and out the drain hole in the pump body, especially

when the engine is shut down. Fuel pumps with this

seal arrangement are identified by a "star" stamped on

the ground face of the pump cover.

10-3-29