TM 5-3895-359-14&P

the pump body so the seal starts straight into the pump

4. Lubricate the pump shaft and insert the square end

flange. Then drive the seal in until it bottoms.

of the shaft into the opening at the gear side of the

pump body and through the oil seals as shown in Fig.

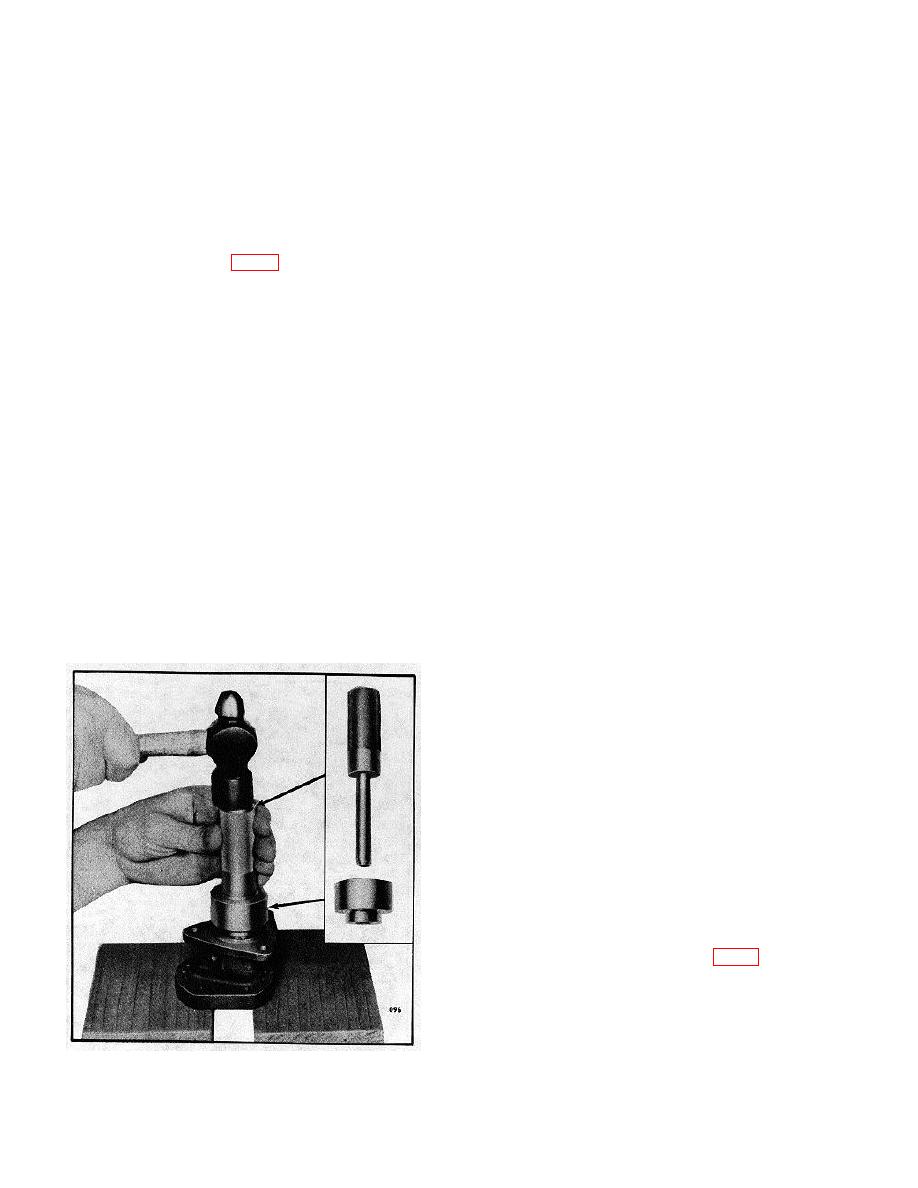

c. Place the shorter end of the adaptor J 1508-9

10.

over the pilot and against the shoulder of the

5. Place the driven shaft and gear assembly in the

installer handle. Place the outer oil seal on the

pump body.

pilot of the installer handle with the lip of the

seal facing the adaptor. Then insert the pilot of

NOTE: The driven gear must be centered on the shaft

the installer handle into the pump body and

to give proper end clearance. Also, the chamfered end

drive the seal in (Fig. 9) until the shoulder of

of the gear teeth of the production gear must face the

the adaptor contacts the pump body. Thus the

pump body. If a service replacement gear with a slot is

oil seals will be positioned so that the space

used, the slot must face toward the pump cover.

between them will correspond with the drain

holes located in the bottom of the pump body.

6. Lubricate the gears and shafts with clean engine oil.

2. Clamp the pump body in a bench vise (equipped with

7. Apply a thin coat of quality sealant on the face of the

soft jaws) with the valve cavity up. Lubricate the outside

pump cover outside of the gear pocket area. Then

diameter of the valve and place it in the cavity with the

place the cover against the pump body with the two

hollow end up. Insert the spring inside of the valve and

dowel pins in the cover entering the holes in the pump

the pin inside of the spring. With a new gasket in place

body. The cover can be installed in only one position

next to the head of the valve plug, place the plug over

over the two shafts.

the spring and thread it into the pump body. Tighten the

1/2"-20 plug to 18-22 lb-ft (24-30 Nm) torque.

NOTE: The coating of sealant must be extremely thin

since the pump clearances have been set up on the

3. Install the fuel pump drive gear over the end of the

basis of metal-to-metal contact. Too much sealant

drive shaft which is not squared (so the slot in the gear

could increase the clearances and affect the efficiency

will face the plain end of the shaft). This operation is

of the pump. Use care that sealant is not squeezed into

very important, otherwise fine score marks caused by

the gear compartment, otherwise damage to the gears

pressing the gear into position from the square end of

and shafts may result.

the shaft may cause rapid wear of the oil seals. Press

the gear beyond the gear retaining ball detent. Then

8. Secure the cover in place with eight bolts and lock

place the ball in the detent and press the gear back until

washers, tightening the bolts alternately and evenly.

the end of the slot contacts the ball.

9. After assembly, rotate the pump shaft by hand to

make certain that the parts rotate freely. If the shaft

does not rotate freely, attempt to free it by tapping a

corner of the pump.

10. Install 1/8" pipe plugs in the upper unused drain

holes.

11. If the pump is not to be installed immediately, place

plastic shipping plugs in the inlet and outlet openings to

prevent dirt or other foreign material from entering the

pump.

Install Fuel Pump

The pump must always be installed with the inlet

opening in the pump cover (marked "RH IN") on the side

toward the cylinder block. Note in Fig. 2 that the

Fig. 9 - Installing Outer Oil Seal

10-3-34