TM 5-3895-359-14&P

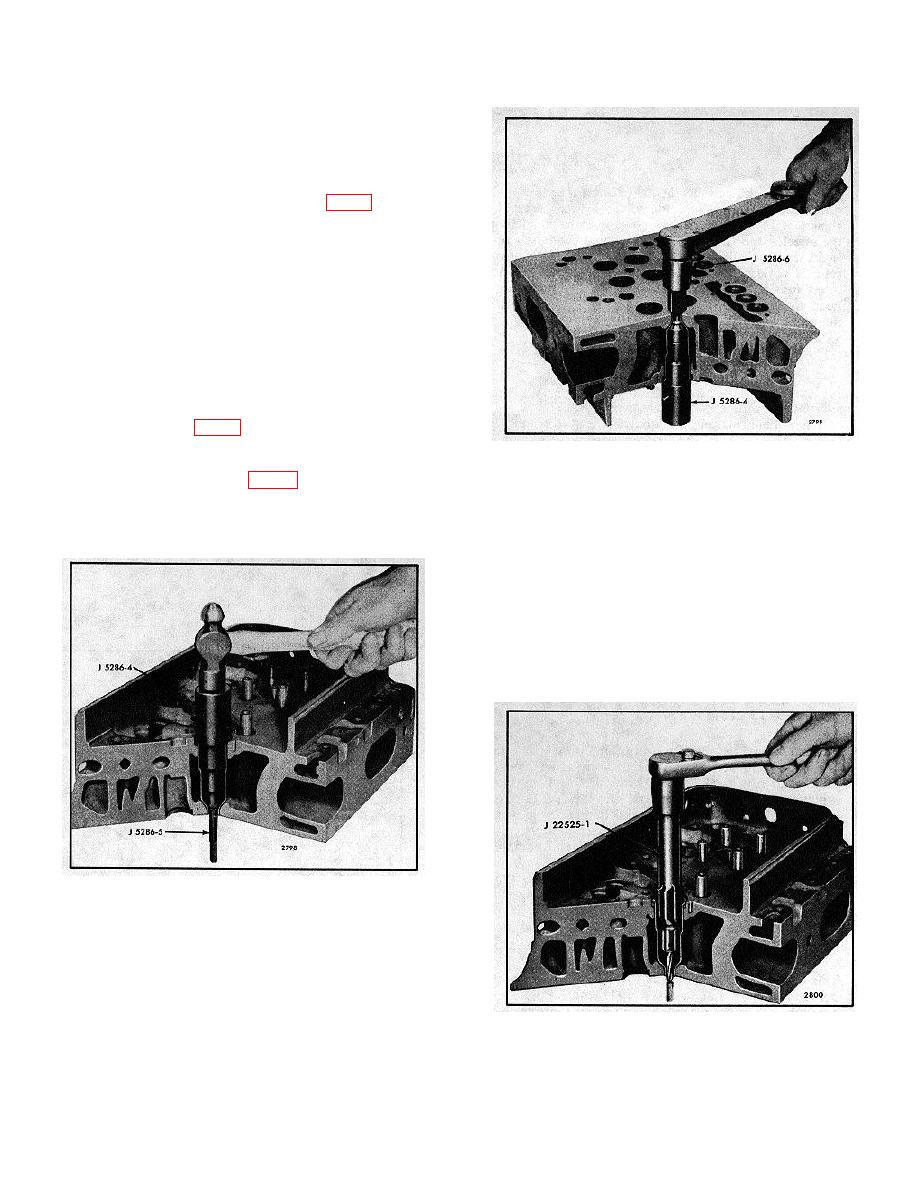

4. With the injector tube properly positioned in the

cylinder head, upset (flare) the lower end of the injector

tube as follows:

a. Turn the cylinder head bottom side up, remove the

pilot J 5286-5 and thread the upsetting die J 5286-6 into

the tapped end of the installer J 5286-4 (Fig. 3).

b. Then, using a socket and torque wrench, apply

approximately 30 Ib-ft (41 Nm) torque on the upsetting

die.

c. Remove the installing tools and ream the injector

tube as outlined below.

Ream Injector Tube

After an injector tube has been installed in a cylinder

head, it must be finished in three operations: First, hand

nut and spray tip; second, spot-faced to remove excess

Fig. 3 - Upsetting Injector Tube

stock at the lower end of the injector tube; and third,

NOTE: The reamer should be turned in a clockwise

direction only, both when inserting and when

seating surface for the bevel or the lower end of the

withdrawing the. reamer, because movement in the

injector nut. Reaming must be done carefully and

opposite direction will dull the cutting edges of the flutes.

without undue force or speed so as to avoid cutting

through the thin wall of the injector tube.

1. Ream the injector tube for the injector nut and spray

tip. With the cylinder head right side up and the injector

tube free from dirt, proceed with the first reaming

operation as follows:

a. Place a few drops of light cutting oil on the

reamer flutes, then carefully position the reamer

J 22525-1 in the injector tube.

Fig. 2 - Installing Injector Tube

Fig. 4 - Reaming Injector Tube for Injector Body Nut

and Spray Tip

10-3-26