TM 5-3895-359-14&P

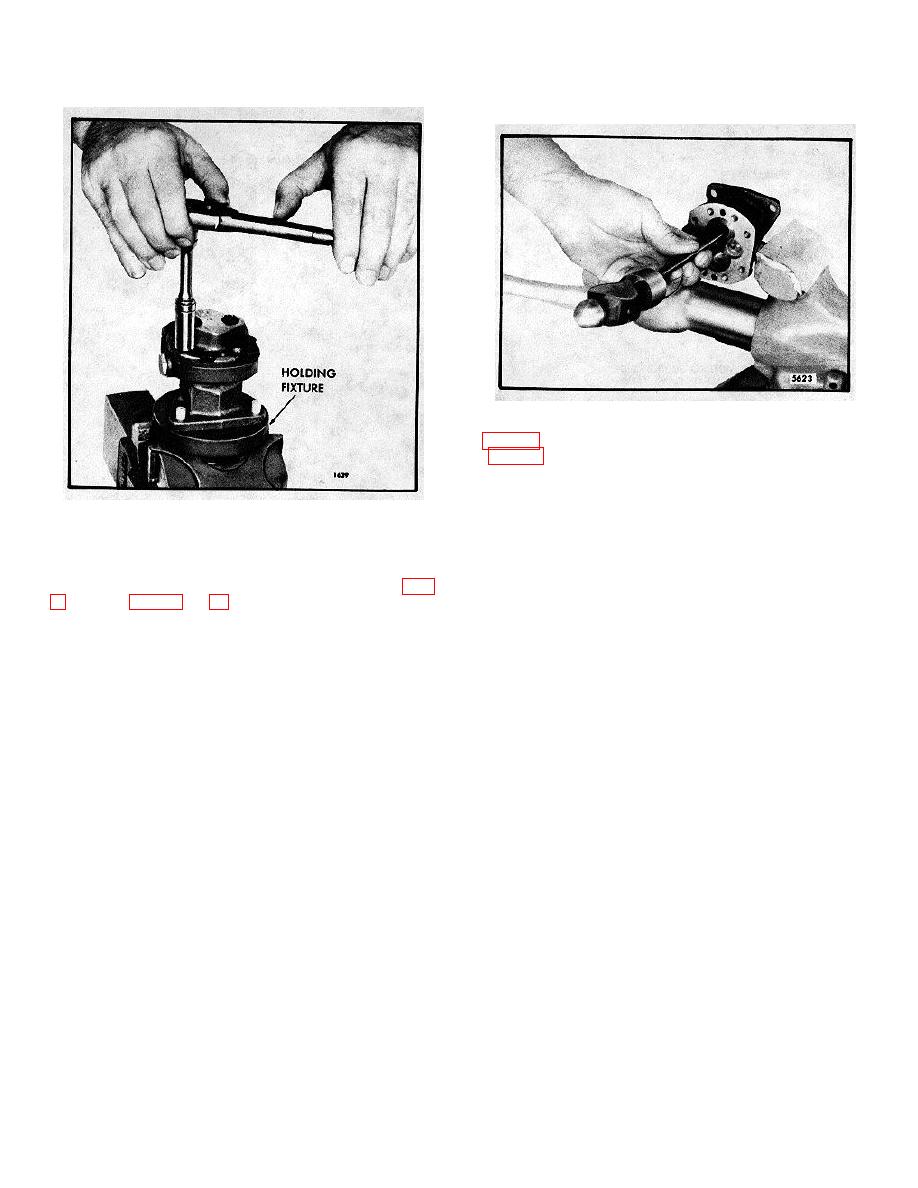

Fig. 6 - Removing Oil Seals

7. If the oil seals need replacing, remove them with oil

the end of the tool with a hammer to remove the outer

and inner seals.

Fig. 5 - Removing Pump Cover

NOTE: Observe the position of the oil seal lips before

removing the old seals to permit installation of the new

Disassemble Fuel Pump

seals in the same position.

With the fuel pump removed from the engine and

Inspection

mounted in holding fixture J 1508-10 as shown in Fig.

Clean all of the parts in clean fuel oil and dry them with

follows:

compressed air.

1. Remove the eight cover bolts and withdraw the pump

Oil seals, once removed from the pump body, must be

cover from the pump body. Use care not to damage the

discarded and replaced with new seals.

finished faces of the pump body and cover.

Check the pump gear teeth for scoring, chipping or

2. Withdraw the drive shaft, drive gear and gear

wear. Check the ball slot in the drive gear for wear. If

retaining ball as an assembly from the pump body.

necessary, replace the gear.

3. Press the drive shaft just far enough to remove the

Inspect the drive and driven shafts for scoring or wear.

steel locking ball. Then invert the shaft and gear

Replace the shafts if necessary. The driven shaft is

assembly and press the shaft from the gear. Do not

serviced as a gear and shaft assembly only.

misplace the steel ball. Do not press the squared end of

the shaft through the gear as slight score marks will

The mating faces of the pump body and cover must be

damage the oil seal contact surface.

flat and smooth and fit tightly together. Any scratches or

slight damage may result in pressure leaks. Also check

4. Remove the driven shaft and gear as an assembly

for wear at areas contacted by the gears and shafts.

from the pump body. Do not remove the gear from the

Replace the pump cover or body if necessary.

shaft. The driven gear and shaft are serviced only as an

assembly.

The relief valve must be free from score marks and

burrs and fit its seat in the pump body. If the valve is

5. Remove the relief valve plug and copper gasket.

scored and cannot be cleaned up with fine emery cloth

or crocus cloth, it must be replaced.

6. Remove the valve spring, pin and relief valve from

the valve cavity in the pump body.

Current standard fuel pumps (with 1/4" wide gears)

incorporate a 1/8" shorter pump body with three drain

holes, a 1/8" shorter drive shaft and a cover with a 3/8"

inlet opening.

10-3-32